5-4) REASSEMBLY PROCEDURES

5-4-1 MOUNT RUBBERS

Attach the four Mount Rubbers to the frame. Insert the locating tab of mount rubber into the locating hole of the frame and fix it by tightening M8 flange nut.

M8 Flange nut : 4pcs.

Tightening torque :

NOTE : The mount rubbers are designed to isolate the vibration most effectively by their original stiffness and shape of rubber. Be sure to use the correct mount rubbers attaching them to the correct position.

5-4-2 SOUND INSULATOR

for SOUND-PROOF MODELS

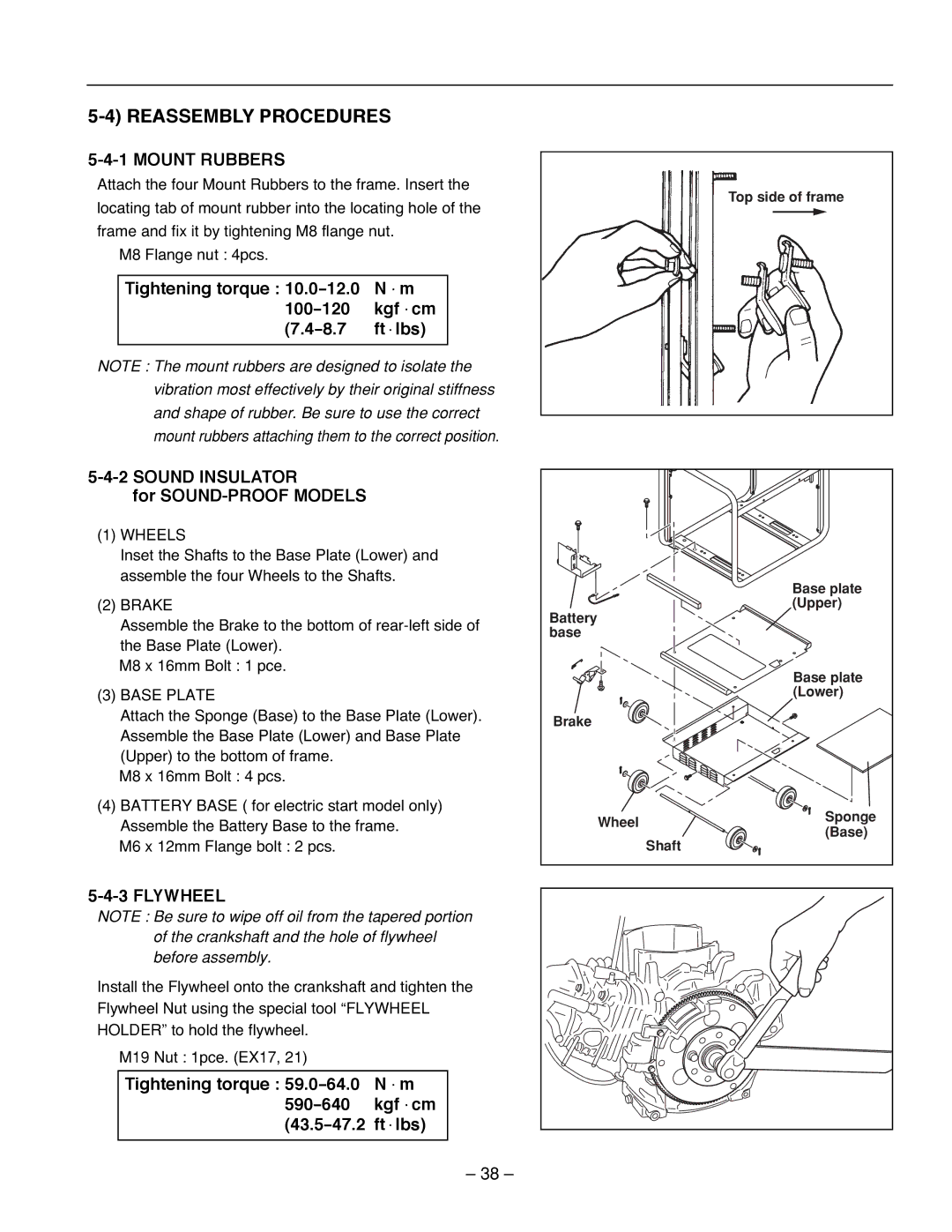

(1)WHEELS

Inset the Shafts to the Base Plate (Lower) and assemble the four Wheels to the Shafts.

(2)BRAKE

Assemble the Brake to the bottom of

M8 x 16mm Bolt : 1 pce.

(3)BASE PLATE

Attach the Sponge (Base) to the Base Plate (Lower). Assemble the Base Plate (Lower) and Base Plate (Upper) to the bottom of frame.

M8 x 16mm Bolt : 4 pcs.

(4)BATTERY BASE ( for electric start model only) Assemble the Battery Base to the frame.

M6 x 12mm Flange bolt : 2 pcs.

5-4-3 FLYWHEEL

NOTE : Be sure to wipe off oil from the tapered portion of the crankshaft and the hole of flywheel before assembly.

Install the Flywheel onto the crankshaft and tighten the Flywheel Nut using the special tool “FLYWHEEL HOLDER” to hold the flywheel.

M19 Nut : 1pce. (EX17, 21)

Tightening torque :

Top side of frame

| Base plate | |

Battery | (Upper) | |

| ||

base |

| |

| Base plate | |

| (Lower) | |

Brake |

| |

Wheel | Sponge | |

(Base) | ||

| ||

| Shaft |

– 38 –