MAINTENANCE

GREASING INNER AND OUTER DRAFT BEAM

PIVOT POINTS

Locate the grease zerks on the inner and outer draft beam pivot bosses. Inject

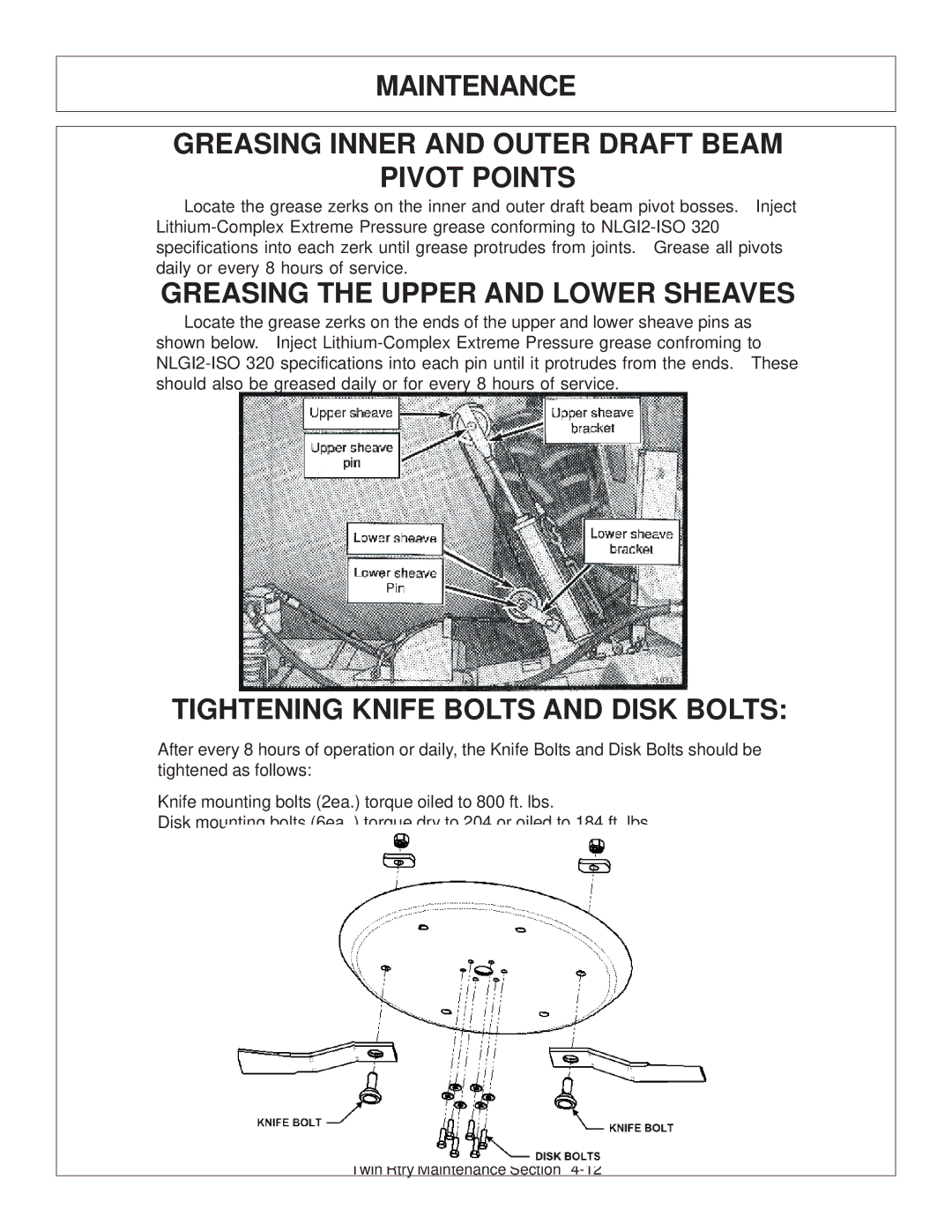

GREASING THE UPPER AND LOWER SHEAVES

Locate the grease zerks on the ends of the upper and lower sheave pins as shown below. Inject

TIGHTENING KNIFE BOLTS AND DISK BOLTS:

After every 8 hours of operation or daily, the Knife Bolts and Disk Bolts should be tightened as follows:

Knife mounting bolts (2ea.) torque oiled to 800 ft. lbs.

Disk mounting bolts (6ea. ) torque dry to 204 or oiled to 184 ft. lbs.

Twin Rtry Maintenance Section