TWIN ROTARY ASSEMBLIES

Tiger Corporation

3301 N. Louise Ave Sioux Falls, SD

PARTS LISTING WITH MOUNTING AND OPERATING INSTRUCTIONS

TO THE OWNER / OPERATOR / DEALER

Tiger Corporation

FORWARD

Page

ASSEMBLY / MOUNTING SECTION

TABLE OF CONTENTS

CAUTION - YOUR SAFETY IS AT RISK

This symbol means

Page

SAFETY

SAFETY SECTION

Practice all usual and customary safe working precautions and

General Safety Instructions and Practices

SAFETY

LEA EL INSTRUCTIVO

SAFETY

DANGER

SG-10

SAFETY

DANGER DANGER

DANGER DANGER DANGER

sure you abide by the following rules

SAFETY

SG-23

SAFETY

DANGER DANGER

SG-20

DANGER

SAFETY

DANGER

DANGER

DANGER

SAFETY

DANGER

Do not put hands or feet under mower decks. Blade Contact can result

DANGER

SAFETY

STOP MOWING IF PASSERSBY ARE WITHIN 100 YARDS UN- LESS

DANGER

SAFETY

DANGER

DANGER

In addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also to Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. SG-18

SEE YOUR

DEALER

SAFETY

LOCATION 22839 MOWER DECK 22840 INSIDE OF CAB 24028 MOWER DECK

SAFETY

10” x 5.5” MOWER DECK 18.25” x10” HYDRAULIC TANK

LOCATION 42350 MOWER DECK 33743 INSIDE OF CAB 42399 MOWER DECK

SAFETY

42400 MOWER DECK

LOCATION 6T3217 MOWER DECK 6T3219 INSIDE OF CAB

SAFETY

6T3220 FRONT PUMP MOUNT 6T3221 INSIDE OF CAB

LOCATION 6T3222 INSIDE OF CAB INSIDE OF CAB 6T3224 MOWER DECK

SAFETY

6T3230 INSIDE OF CAB

LOCATION 6T3233 HYDRAULIC TANK 6T3234 INSIDE OF CAB

SAFETY

6T3236 MOWER DECK HYDRAULIC TANK 6T3243 INSIDE OF CAB

LOCATION 6T3249A MOWER DECK 6T3261 MOWER DECK TB1011 MOWER DECK

SAFETY

34852 HYDRAULIC TANK

SAFETY

50023

SAFETY

DRILLING HOLES INTO UNKNOWN AREAS, wires and other parts may

DESCRIPTION

DUTIES

SAFETY FEDERAL LAWS AND REGULATIONS

Employer-Employee Operator Regulations

This Act Seeks

Assembly Section

ASSEMBLY SECTION

TRACTOR PREPARATION

ASSEMBLY

CRANKSHAFT ADAPTER

ASSEMBLY ADJUSTING REAR WHEELS

CABLE CONTROL LEVER STAND

MAIN FRAME MOUNTING

ASSEMBLY LIFT VALVE MOUNT

SOLENOID BRAKE VALVE

ASSEMBLY

WEATHER-PACK/METRI-PACK ASSEMBLY

ASSEMBLY POLY-CARBONATE SAFETY WINDOW

FRONT WORKLAMP RELOCATION

ASSEMBLY INSTALLING MIRROR BRACKET

EXAUST SUPPORT BRACKET MUFFLER MUFFLER SHIELD MIRROR BRACKET

ASSEMBLY EXHAUST MOUNT

Picture # Picture #

ASSEMBLY

AFTER WIRING

ASSEMBLY SWITCH MOUNTING

HYDRAULIC TANK INSTALLATION

BEFORE WIRING

Assembly Section

ASSEMBLY

ASSEMBLY

GENERAL HOSE INSTALLATION

TEMPERATURE GAUGE MOUNTING

FRONT PUMP MOUNTING

Installing straight, 45 degree and 90 degree O-ring fittings requires that the O- ring, washer and nut A be up against the swivel body B. Insert the swivel and turn in until the swivel is pointed in the right direction and the O-ring contact is made. Hold swivel in set direction with a wrench and turn the O-ring nut away from the swivel body and carefully tighten

INSTALLING O-RING FITTINGS

SUB-FRAME AXLE BRACE MTG

ASSEMBLY

ASSEMBLY

CABLE LIFT DRAFT BEAM INSTALLATION

Install ½” O-ring breather into butt port of inboard cylinder. In all fittings in the rod end of the cylinder according to diagrams in parts section. These fittings should be positioned to face the butt end of the cylinder

LIFT CONTROL FEEDLINES

ASSEMBLY DRAFT BEAM MOUNTING

DECK / MOTOR FEEDLINE

ASSEMBLY

DECK MOUNTING AND LIFT ASSEMBLY

Check for oil leaks at all fittings and connections using a piece of paper or cardboard. DO NOT USE HANDS TO CHECK FOR FLUID LEAKS

MOWER TESTING

ASSEMBLY TURNBUCKLE ADJUSTMENT

FINAL PREPARATION FOR OPERATION

DRAFT BEAM MOUNTING

ASSEMBLY COMBO LIFT DRAFT BEAM INSTALLATION

Assembly Section

Check that all grease zerks have been installed in the draft beams pivot arm, left linkage arm, right linkage arm, and cylinder mounting ears

ASSEMBLY DECK MOUNTING

DECK / MOTOR FEEDLINE

CHECK FOR FLUID LEAKS

ASSEMBLY DECK / MOTOR FEEDLINE MOUNTING cont

STOP BOLT ADJUSTMENT

3-POINT DECK TILT CYLINDER

MOWER TESTING

ASSEMBLY FINAL PREPARATION FOR OPERATION

Assembly Section

ASSEMBLY

OPERATION

OPERATION SECTION

Twion Rtry Operation Section

OPERATION

OPERATION STARTING TRACTOR AND MOWER

MOWER OPERATION

OPERATION CONTROL LOCATION AND FUNCTIONS

Once on location, lower the mower deck slightly above the material to be cut, so the mower does not have to start under a load. Bring the R.P.M. of the tractor up to 1200 and engage the side mower. If a rear mower is being used, allow the R.P.M. to return to 1200 before engaging the rear mower

OPERATION

3. Push switch DOWN to reverse 4. Allow chaff to clear

REVERSE FAN OPERATION

1. Normal operating position is with fan switch ON upper position

2. Turn fan switch OFF center position, wait at least 3 seconds

Transporting under the units own power

OPERATION TRANSPORTING MOWER

Transporting unit by flatbed trailer

OPERATION

Next, switch the hose ends and reconnect to form two separate closed loops, see diagram below. Disconnect the lift cable from the head and secure the loose end back onto the cable with the cable clevis. Remove the keeper bolt and draft beam outer pivot pin. Separate the mower head from the tractor. Now reinstall the pivot pin and keeper bolts into the draft beam to prevent loss. OPEN THE BALL VALVES ON THE HYDRAULIC RESERVOIR BEFORE STARTING TRACTOR AGAIN! Serious damage will be caused if tractor is started with the ball valves closed

OPERATION

INSPECTION SHEETS

OPERATION

Rotary Mower PRE-OPERATION Inspection

Tractor ID# Make Date Shift

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION Inspection

OPERATION

Tractor ID# Make Date Shift

OPERATION

FRONT END LOADER PRE-OPERATION Inspection

Mower ID# Make Date Shift

DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER

DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER

OPERATION

TRACTOR PRE-OPERATION Inspection

Tractor ID# Make Date Shift

Twion Rtry Operation Section

OPERATION

MAINTENANCE

MAINTENANCE SECTION

Tiger Mowers are designed for high performance and rugged durability, yet with simplified maintenance. The purpose of this section of the manual is to help the operator in the regular servicing of the mower. Regular maintenance at the intervals mentioned will result in the maximum efficiency and long life of the Tiger Mower

MAINTENANCE PRECAUTIONS

BREAK IN PERIOD

MAINTENANCE

COMMENTS

MAINTENANCE REGULAR MAINTENANCE

DAILY OR EVERY 8 HOURS

SERVICE

YEARLY OR EVERY 500 HOURS

MAINTENANCE WEEKLY OR EVERY 50 HOURS

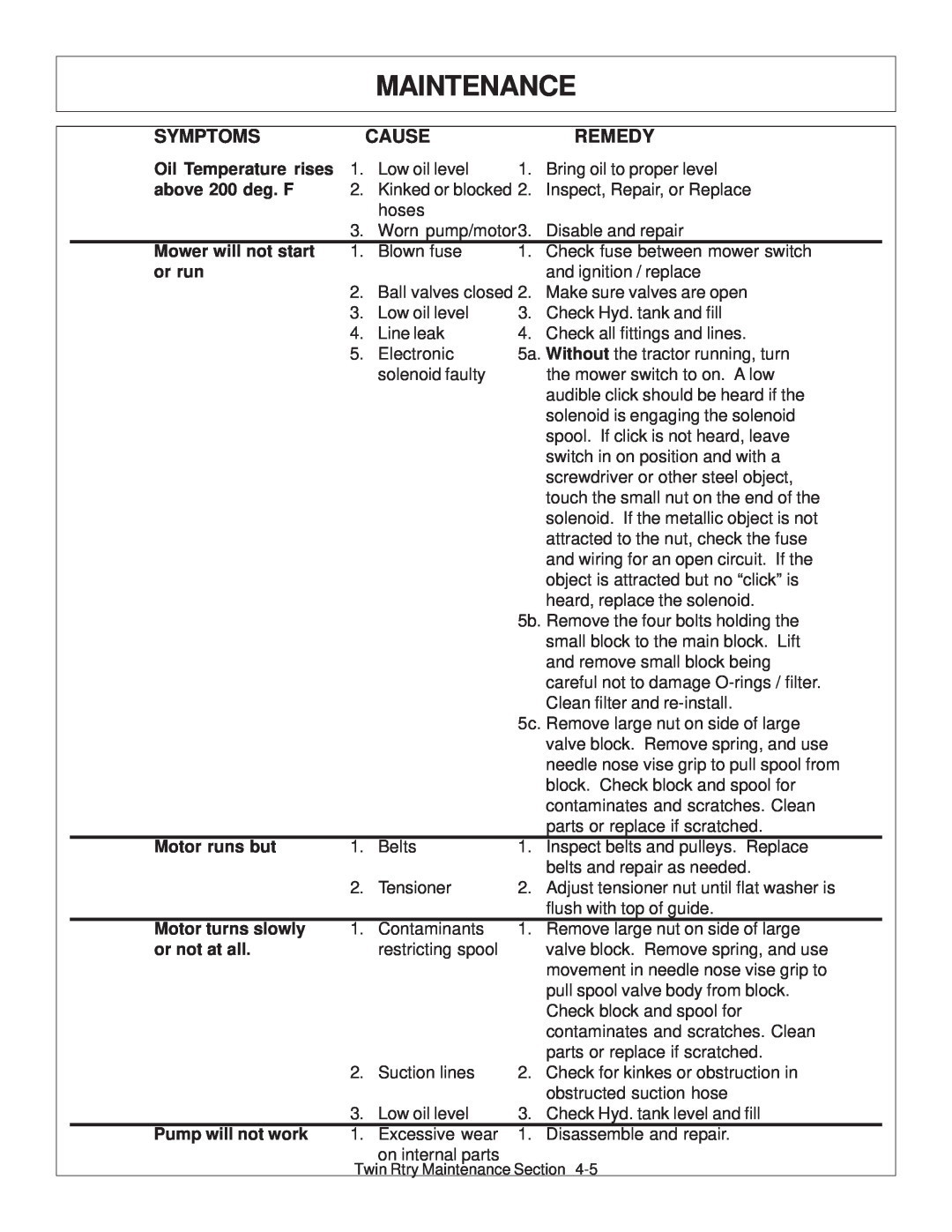

TROUBLESHOOTING

MONTHLY OR EVERY 150 HOURS

CAUSE

MAINTENANCE

SYMPTOMS

Oil Temperature rises

Motor will not work

MAINTENANCE

MAINTENANCE TORQUE SPECIFICATIONS

Description

LUBRICATION RECOMMENDATIONS

MAINTENANCE

General Specification

CLEANING THE SUPERCOAT HARD-COAT

MAINTENANCE POLYCARBONATE CARE & MAINTENANCE

GRAFFITI REMOVAL

REPLACEING IN-TANK HYDRAULIC FILTER

DETAILED MAINTENANCE

RECOMMENDED FILLING INSTRUCTIONS FOR HYDRAULIC RESERVIORS

MAINTENANCE

REPLACEING HIGH PRESSURE HYDRAULIC FILTER ELEMENT

MAINTENANCE DETAILED MAINTENANCE

HEAD BOWL

GREASING THE UPPER AND LOWER SHEAVES

MAINTENANCE GREASING INNER AND OUTER DRAFT BEAM PIVOT POINTS

TIGHTENING KNIFE BOLTS AND DISK BOLTS

DRIVE SHAFT YOKE, U-JOINT & STUB SHAFT

MAINTENANCE GREASING PUMP DRIVE SHAFT COUPLER

GREASING THE CASTER WHEEL SWIVEL

MAINTENANCE ADJUSTING THE CABLE LIFT

BALL VALVES

MAINTENANCE GREASING CASTER FRAME PIVOT POINTS

TIGHTENING SPINDLE BOLTS

MAINTENANCE GREASING SPINDLE

Failure to follow the following warnings and instructions may result

ROTARY KNIFE REPLACEMENT

INSPECTION OF ROTARY KNIVES

MAINTENANCE

serious injury or damage to the equipment or property

REPLACEMENT OF ROTARY DISK

MAINTENANCE

Failure to follow the following warnings and instructions may result

INSTALLATION AND BEARING ADJUSTMENT

MAINTENANCE HEAVY DUTY SPINDLE ASSEMBLY

THE SPINDLE ASSEMBLY

MAINTENANCE BEARING INSTALLATION

MAINTENANCE BEARING ADJUSTMENT

Maintenance Section

MAINTENANCE DAILY MAINTENANCE SCHEDULE

FORD TS 115-135A CAB, WOC, TWIN ROTARY

PARTS SECTION

Direct any questions regarding parts to

PARTS ORDERING GUIDE

Tiger Corporation

3301 N. Louise Ave Sioux Falls, SD

ASSEMBLY

PARTS SECTION TABLE OF CONTENTS

SECTION

Parts Section

TRACTOR MOUNT KIT - MAIN FRAME

AVAIL

TRACTOR MOUNT KIT - MAIN FRAME

DESCRIPTION

06700006

Parts Section

TRACTOR MOUNT KIT - HYDRAULICS, TRR

FRONT PUMP - REFER TO MAIN FRAME PARTS

TRACTOR MOUNT KIT - HYDRAULICS, TRR

DESCRIPTION

MAIN FRAME - REFER TO MAIN FRAME PARTS

Parts Section

TRACTOR MOUNT KIT - HYDRAULICS, TRAILKAT

FRONT PUMP - REFER TO MAIN FRAME PARTS

TRACTOR MOUNT KIT - HYDRAULICS, TRAILKAT

DESCRIPTION

MAIN FRAME - REFER TO MAIN FRAME PARTS

Parts Section

TRACTOR MOUNT KIT - BRACE/BATT, CAB/WOC

DESCRIPTION

TRACTOR MOUNT KIT - BRACE/BATT, CAB/WOC

MAIN FRAME - REFER TO MAIN FRAME PARTS

Parts Section

CABLE LIFT VALVE - 2SP, CAB/WOC

DESCRIPTION

CABLE LIFT VALVE - 2SP, CAB/WOC

Parts Section

COMBO LIFT VALVE - 2SP, CAB/WOC

DESCRIPTION

COMBO LIFT VALVE - 2SP, CAB/WOC

Parts Section

CABLE LIFT VALVE - 3SP, CAB/WOC

DESCRIPTION

CABLE LIFT VALVE - 3SP, CAB/WOC

Parts Section

COMBO LIFT VALVE - 3SP, CAB/WOC

DESCRIPTION

COMBO LIFT VALVE - 3SP, CAB/WOC

Parts Section

MIRROR BRACKET

DESCRIPTION

MIRROR BRACKET

COLLAR,CLAMP,EXHAUST,TS115A

Parts Section

HYDRAULIC COOLER ASSEMBLY, CAB

AVAIL

HYDRAULIC COOLER ASSEMBLY, CAB

DESCRIPTION

06510029

DESCRIPTION

BOOM POLYCARBONATE CAB SAFETY WINDOW KIT

POLYCARBONATE, NHTSA 115, DOOR, RH

U-BOLT,3.25x5.00x.50,20NF,GR8

NON-CAB STEEL CANOPY - OPTIONAL

DESCRIPTION

DESCRIPTION

EXHAUST MOUNT

TUBE,EXHAUST RELOCATE,TSA,6CYL

DESCRIPTION

OPTIONAL PUMP AND GRILL GUARD KIT

DESCRIPTION

BRAKE VALVE SOLENOID

AVAIL

SOLENOID VALVE SWITCH AND WIRING

DESCRIPTION

06510027

Parts Section

TWIN ROTARY COMMON SECTION

COMMON PARTS SECTION

PAGE

TABLE OF CONTENTS

ASSEMBLY

SECTION

Tiger Corporation

PARTS ORDERING GUIDE

3301 N. Louise Ave Sioux Falls, SD

Twin Rotary Common Section

REAR ROTARY DECK ASSEMBLY

CURRENT MOTOR, M365 - 2 GEAR

REAR ROTARY DECK ASSEMBLY

DESCRIPTION

06504011

NOTE ORIENTATION OF ITEM 34, LARGE ZERK FORWARD

TRAILKAT REAR ROTARY DECK ASSY

06320002

TRAILKAT REAR ROTARY DECK ASSY

Twin Rotary Common Section

REAR ROTARY CASTER WHEEL & 3PT ASSEMBLY

BEARING, CONE, CASTER WHEEL

REAR ROTARY CASTER WHEEL & 3PT ASSEMBLY

DESCRIPTION

NOT SHOWN

Twin Rotary Common Section

REAR ROTARY HYDRAULICS

VALVE,BRAKE,SOL,3000PSI,METRI

REAR ROTARY HYDRAULICS

DESCRIPTION

RTRY, 60” CPLT - HP W/FBAR TRR

Twin Rotary Common Section

60” ROTARY MOTOR

06504016

MOTOR ASSEMBLY 2 1/4” COMPLETE TRB60

60” ROTARY MOTOR

DESCRIPTION

Twin Rotary Common Section

PUMP - SERVICE PARTS

DESCRIPTION

PUMP - SERVICE PARTS

Twin Rotary Common Section

2 SP HUSCO - LOAD SENSE

DESCRIPTION

2 SP HUSCO - LOAD SENSE

Twin Rotary Common Section

2 SP HUSCO - LOAD SENSE

DESCRIPTION

2 SP HUSCO - LOAD SENSE

Twin Rotary Common Section

3 SP HUSCO - LOAD SENSE CABLE

DESCRIPTION

3 SP HUSCO - LOAD SENSE CABLE

Twin Rotary Common Section

3 SP HUSCO - LOAD SENSE COMBO

DESCRIPTION

3 SP HUSCO - LOAD SENSE COMBO

Twin Rotary Common Section

SIDE COOLER

DESCRIPTION

SIDE COOLER

DESCRIPTION

SAFETY STAND

DESCRIPTION

CASTER WHEEL ASSEMBLY

RIM, OUTER/RR RTRY CASTER ASSY

DESCRIPTION

BRAKE VALVE ASSEMBLY W/ METRI PAK

SWITCHBOX SERVICE PARTS

Twin Rotary Common Section

SWITCHBOX SCHEMATIC

Warranty Section

WARRANTY SECTION

Page

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THOSE EXPRESSED HEREIN

WARRANTY INFORMATION

SAFETY IS YOU

ONE LAST WORD

OWNER REQUIREMENTS

TO THE OWNER / OPERATOR / DEALER

OPERATOR REQUIREMENTS

Printed in USA Tiger Corporation