|

| Diagnostics |

|

| |

|

|

|

|

| |

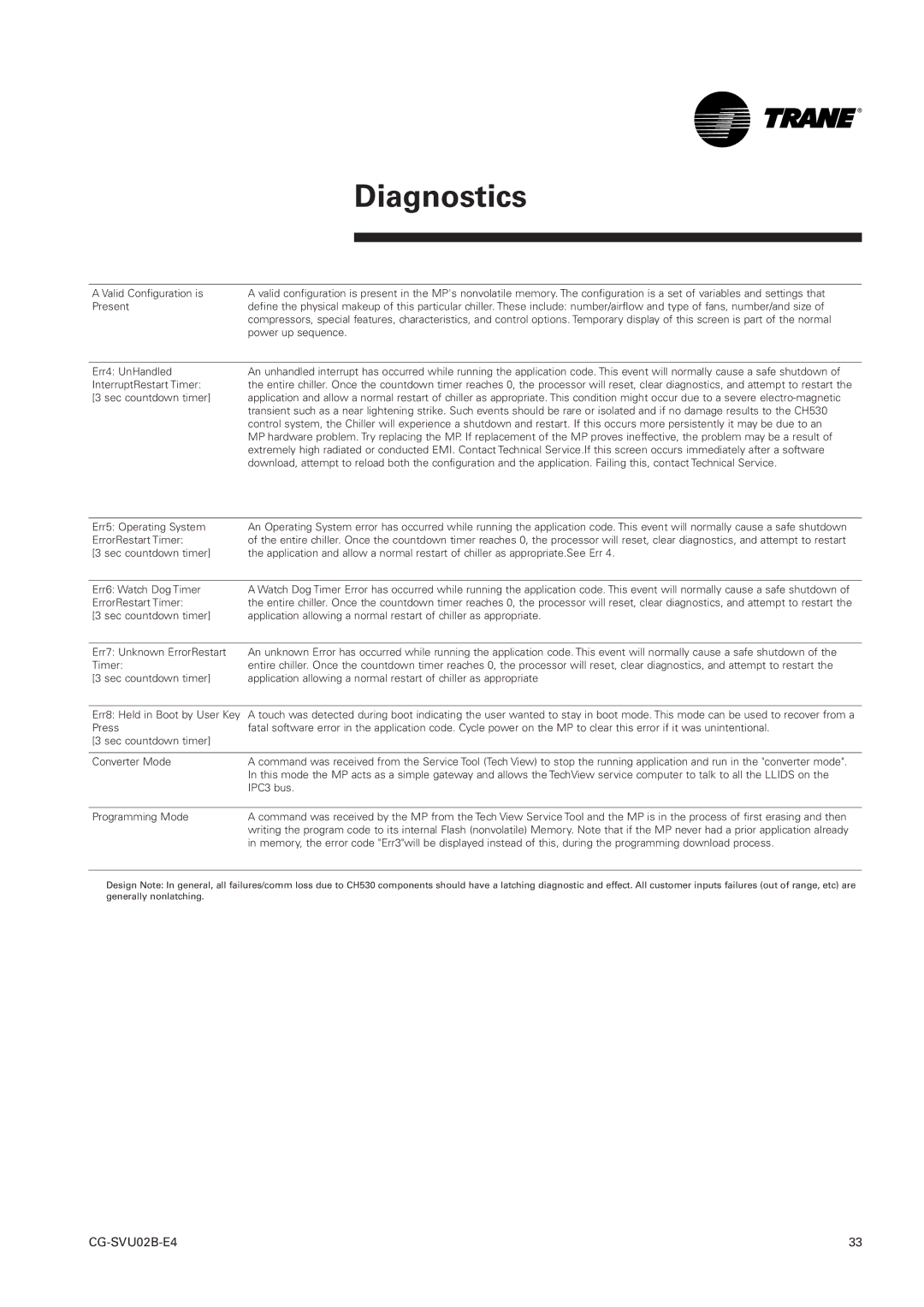

A Valid Configuration is | A valid configuration is present in the MP's nonvolatile memory. The configuration is a set of variables and settings that | |

Present | define the physical makeup of this particular chiller. These include: number/airflow and type of fans, number/and size of | |

| compressors, special features, characteristics, and control options. Temporary display of this screen is part of the normal | |

| power up sequence. | |

|

| |

Err4: UnHandled | An unhandled interrupt has occurred while running the application code. This event will normally cause a safe shutdown of | |

InterruptRestart Timer: | the entire chiller. Once the countdown timer reaches 0, the processor will reset, clear diagnostics, and attempt to restart the | |

[3 sec countdown timer] | application and allow a normal restart of chiller as appropriate. This condition might occur due to a severe | |

| transient such as a near lightening strike. Such events should be rare or isolated and if no damage results to the CH530 | |

| control system, the Chiller will experience a shutdown and restart. If this occurs more persistently it may be due to an | |

| MP hardware problem. Try replacing the MP. If replacement of the MP proves ineffective, the problem may be a result of | |

| extremely high radiated or conducted EMI. Contact Technical Service.If this screen occurs immediately after a software | |

| download, attempt to reload both the configuration and the application. Failing this, contact Technical Service. | |

|

| |

Err5: Operating System | An Operating System error has occurred while running the application code. This event will normally cause a safe shutdown | |

ErrorRestart Timer: | of the entire chiller. Once the countdown timer reaches 0, the processor will reset, clear diagnostics, and attempt to restart | |

[3 sec countdown timer] | the application and allow a normal restart of chiller as appropriate.See Err 4. | |

|

| |

Err6: Watch Dog Timer | A Watch Dog Timer Error has occurred while running the application code. This event will normally cause a safe shutdown of | |

ErrorRestart Timer: | the entire chiller. Once the countdown timer reaches 0, the processor will reset, clear diagnostics, and attempt to restart the | |

[3 sec countdown timer] | application allowing a normal restart of chiller as appropriate. | |

|

| |

Err7: Unknown ErrorRestart | An unknown Error has occurred while running the application code. This event will normally cause a safe shutdown of the | |

Timer: | entire chiller. Once the countdown timer reaches 0, the processor will reset, clear diagnostics, and attempt to restart the | |

[3 sec countdown timer] | application allowing a normal restart of chiller as appropriate | |

|

| |

Err8: Held in Boot by User Key | A touch was detected during boot indicating the user wanted to stay in boot mode. This mode can be used to recover from a | |

Press | fatal software error in the application code. Cycle power on the MP to clear this error if it was unintentional. | |

[3 sec countdown timer] |

|

|

|

| |

Converter Mode | A command was received from the Service Tool (Tech View) to stop the running application and run in the "converter mode". | |

| In this mode the MP acts as a simple gateway and allows the TechView service computer to talk to all the LLIDS on the | |

| IPC3 bus. | |

|

| |

Programming Mode | A command was received by the MP from the Tech View Service Tool and the MP is in the process of first erasing and then | |

| writing the program code to its internal Flash (nonvolatile) Memory. Note that if the MP never had a prior application already | |

| in memory, the error code "Err3"will be displayed instead of this, during the programming download process. | |

Design Note: In general, all failures/comm loss due to CH530 components should have a latching diagnostic and effect. All customer inputs failures (out of range, etc) are generally nonlatching.

33 |