IV. OPERATION

IV. a - REFRIGERATORS:

Both refrigerators and freezers do not require manual defrosting. During normal operation, a refrigerator continuosly circulates above freezing cabinet air through the coil. A compressor “OFF” cycle occurs every hour to melt any frost which may accumulate on the coil during the compressor “ON” cycle. The control will read “dEF” when this occurs. With standard holding refrigerators, high relative humidity is also maintained to prevent dehydration of stored product.

IV. b - FREEZERS:

During normal operation, a freezer continuously circulates below freezing cabinet air through the coil. The coil requires a periodic defrosting for proper operation. This is accomplished by an automatic, time activated, temperature/time terminated, defrost program. The controller is preset at the factory for six equally spaced defrost cycles within each

At the start of a freezer defrost cycle, both the compressor and evaporator fans are OFF. The

The total refrigeration system operation is then resumed.

IV. c- HOT FOOD CABINETS:

Hot food cabinet operation is governed by the

Hot food cabinets are delivered from the factory with the control set to the “OFF” position. Follow the instructions in section “VII. t” to get started.

NOTE: A vent is included at the top of all hot food cabinets. The vent opening is factory set and secured for best position. Be certain to make sure this vent is kept free of any obstruction.

V. CARE & MAINTENANCE

WARNING

DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY PARTS OF THE UNIT

V. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long, reliable service life for your Traulsen is to regularly clean the condenser coil.

The condensing unit requires regularly scheduled cleaning to keep the finned condenser clean of lint and dust accummulation. The

°F°C

![]() SET

SET ![]()

![]() )))

)))

°F°C

![]() SET

SET ![]()

![]() )))

)))

efficiently and use less energy.

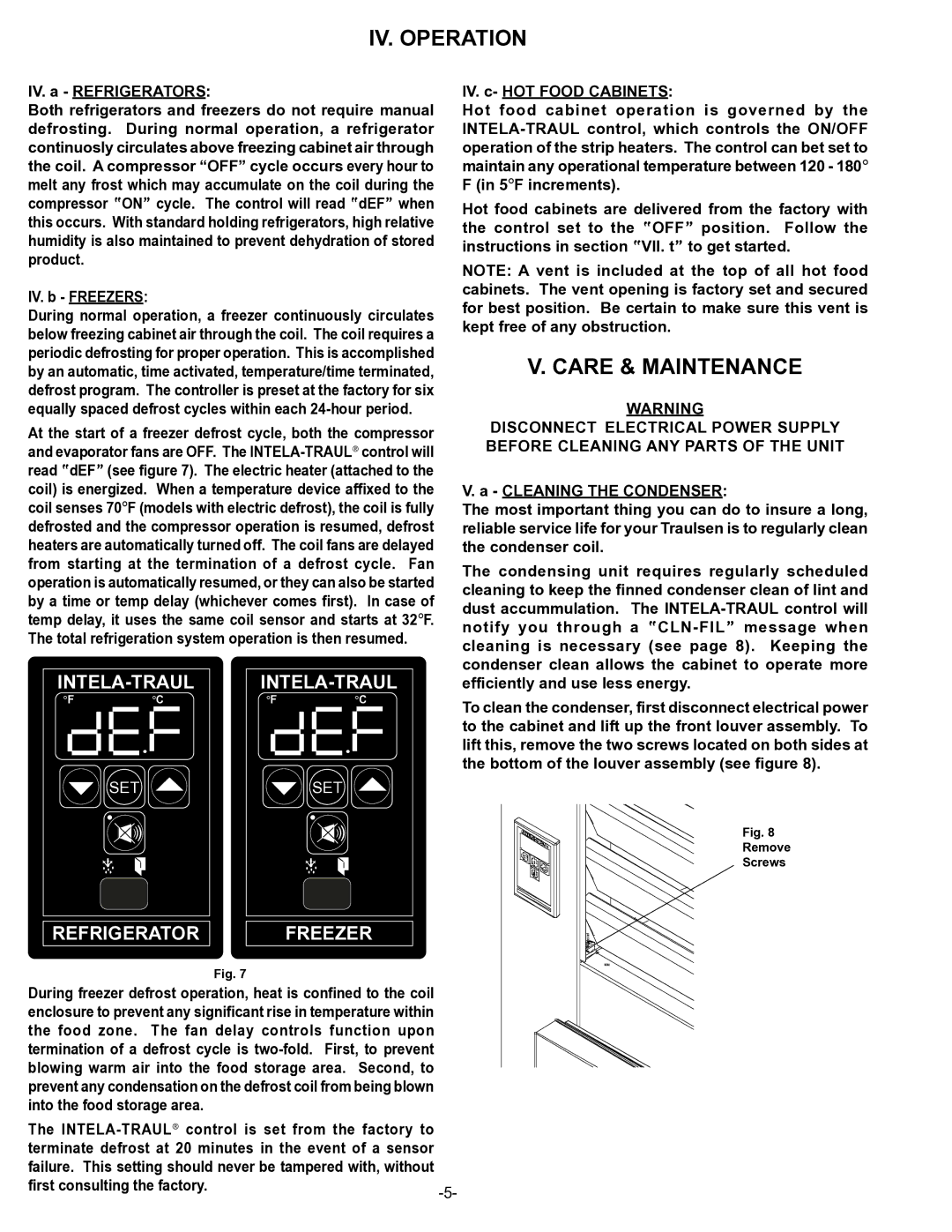

To clean the condenser, first disconnect electrical power to the cabinet and lift up the front louver assembly. To lift this, remove the two screws located on both sides at the bottom of the louver assembly (see figure 8).

Fig. 8

Remove

Screws

REFRIGERATOR | FREEZER |

Fig. 7

During freezer defrost operation, heat is confined to the coil enclosure to prevent any significant rise in temperature within the food zone. The fan delay controls function upon termination of a defrost cycle is

into the food storage area. |

|

The |

|

terminate defrost at 20 minutes in the event of a sensor |

|

failure. This setting should never be tampered with, without |

|

first consulting the factory. | |

|