SECTION2: ASSEMBLY

WARNING: To prevent personal injury or property damage,do not start the engine until all assemblysteps are complete andyou have read and understandthe safety and operating instructions in this manual.

INTRODUCTION

Carefullyfollow these assemblysteps to correctly prepareyour tiller for use. It is recommended that you readthis Section in its entirety before beginning assembly.

NOTE: Various tiller models are presented in this Manual Use only the information appropriate for your tiller model Engine styles vary by model Your

engine may appear differently than those illustrated in this manual.

INSPECTUNIT

Inspectthe unit and carton for damage Lm- mediately after delivery. Contactthe cam- er (trucking company) if you find or suspectdamage. Inform them of the dam-

ageand request instructions for filing a claim. To protect your rights, put your

claim inwriting and ma_la copyto the car- rier within 15 days after the unit has been delive'edContact.

TOOLSMATERIALSNEEDED

Ill 3,8"

(2) 946"

(1)Largead Jstable wrench _Models634F/634Bonly}

(.1J Scissors to trim plastic ties/

(1) Ruler (for belt tension check_

111 Block of wood (to support tiller when remowng wheels)

111 Tire pressure gauge(for modelswith pneumatic tires_

Ill Cleanoil funnel

111 Motor oil Referto the Engine0wner's Manualfor oil specificationsand quantityrequired.

* Adjustablewrenches may Deused,

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE: While unpacking, do not severely bendany control cables.

1.Thetiller weighs approximately133 lbs. Do not attempt to remove it from the ship- ping platform until instructed to do so m these Assembly steps.

2.Removeany packaging materialfrom the carton. Removeany staples from the bottom of the carton and removethe car- ton from the shipping platform.

3.Removeall unassembled partsand the separatehardware bagfrom the carton. Checkthat you havethe items listed in the Loose Parts List (contactyour localdealer or the factory items are missing or dam- aged).

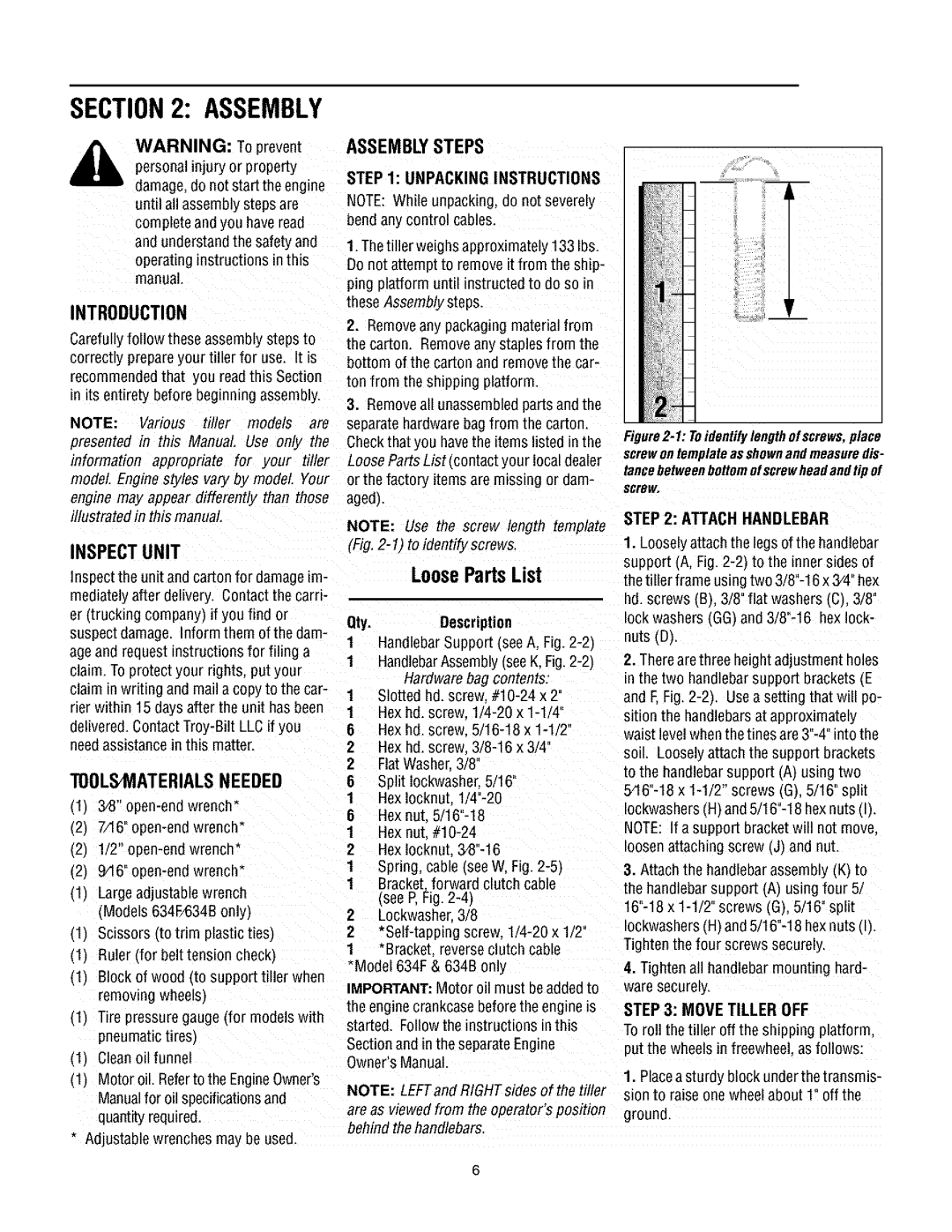

NOTE: Use the screw length template (Fig.

LoosePartsList

Qty. | Description |

1 | HandlebarSupport (seeA, Fig. |

1 | HandlebarAssembly(see K, |

| |

1 | Hardware bag contents: |

Slotted hd. screw | |

1 | Hex hd. screw |

6 | Hex hd. screw |

2Hex hd. screw.

2FlatWasher.3/8

6Split Iockwashe_ 5/16"

1Hex Iocknut.

6Hex nut.

1Hex nut

2Hex Iocknut.

1Spring, cable (see W, Fig.

1Bracket. forward clutch cable

(.seeP, Fig.

2 Lockwasher 3/8

2

1*Bracket reverseclutch cable *Model 634F & 634B only IMPORTANT: Motor oil must beaddedto

the enginecrankcase beforethe engine is started. Followthe instructions inthis Sectionand in the separateEngine Owner'sManual.

NOTE: LEFTandRIGHTsidesofthetiller

are as viewed from the operator's position behind the handlebars.

m

Figure2-1: Toidentifylengthofscrews,place screwontemplateasshownandmeasuredis- tancebetweenbottomofscrewheadandtipof

scrBw,

STEP 2: ATTACH HANDLEBAR

1.Looselyattach the legs of the handlebar support (A, Fig.

2.Therearethree height adjustment holes in the two handlebarsupport brackets (.E and E Fig.

3.Attach the handlebarassembly (.K_to the handlebarsupport (A) using four 5.

IockwashersIHI

4.Tighten all handlebar mounting hard- ware securely.

STEP 3: MOVE TILLER OFF

To roll the tiller off the shipping platform. put the wheels in freewhee as follows:

1.Placea sturdy block underthe transmis- sion to raise one wheelabout l" off the

ground.