Vertical Sidewall Installation

Twist Lock Pipe

Step 1

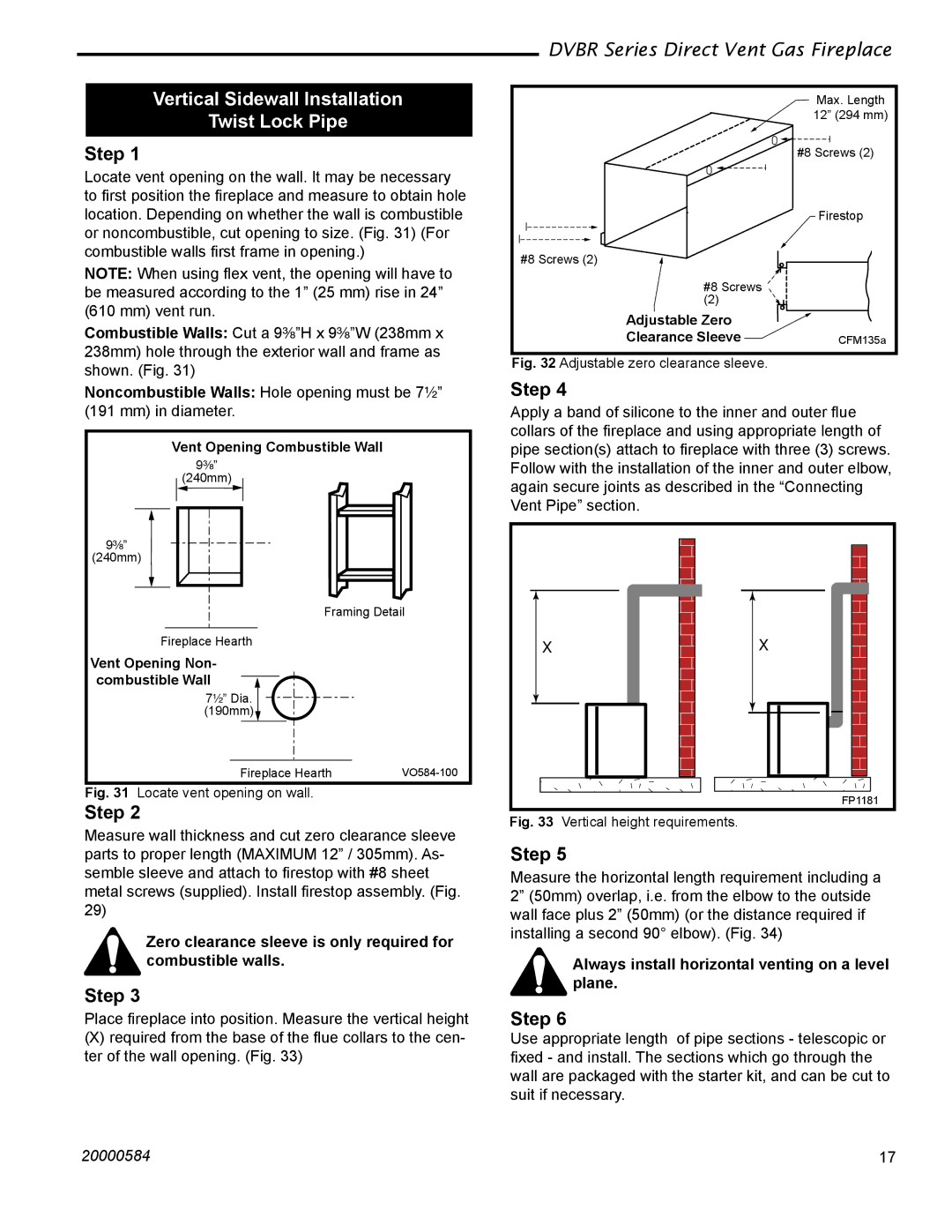

Locate vent opening on the wall. It may be necessary to first position the fireplace and measure to obtain hole location. Depending on whether the wall is combustible or noncombustible, cut opening to size. (Fig. 31) (For combustible walls first frame in opening.)

NOTE: When using flex vent, the opening will have to be measured according to the 1” (25 mm) rise in 24” (610 mm) vent run.

Combustible Walls: Cut a 9³⁄₈”H x 9³⁄₈”W (238mm x 238mm) hole through the exterior wall and frame as shown. (Fig. 31)

Noncombustible Walls: Hole opening must be 7¹⁄₂”

(191 mm) in diameter.

Vent Opening Combustible Wall

9³⁄₈”

(240mm)

9³⁄₈”

(240mm)

Framing Detail

Fireplace Hearth

Vent Opening Non- combustible Wall

7¹⁄₂” Dia. (190mm)

Fireplace Hearth |

Fig. 31 Locate vent opening on wall.

Step 2

Measure wall thickness and cut zero clearance sleeve parts to proper length (MAXIMUM 12” / 305mm). As- semble sleeve and attach to firestop with #8 sheet metal screws (supplied). Install firestop assembly. (Fig. 29)

Zero clearance sleeve is only required for combustible walls.

Step 3

Place fireplace into position. Measure the vertical height

(X)required from the base of the flue collars to the cen- ter of the wall opening. (Fig. 33)

DVBR Series Direct Vent Gas Fireplace

| Max. Length |

| 12” (294 mm) |

| #8 Screws (2) |

| Firestop |

#8 Screws (2) |

|

#8 Screws |

|

(2) |

|

Adjustable Zero |

|

Clearance Sleeve | CFM135a |

Fig. 32 Adjustable zero clearance sleeve.

Step 4

Apply a band of silicone to the inner and outer flue collars of the fireplace and using appropriate length of pipe section(s) attach to fireplace with three (3) screws. Follow with the installation of the inner and outer elbow, again secure joints as described in the “Connecting Vent Pipe” section.

X | X |

| FP1181 |

Fig. 33 | Vertical height requirements. |

Step 5

Measure the horizontal length requirement including a 2” (50mm) overlap, i.e. from the elbow to the outside wall face plus 2” (50mm) (or the distance required if installing a second 90° elbow). (Fig. 34)

Always install horizontal venting on a level plane.

Step 6

Use appropriate length of pipe sections - telescopic or fixed - and install. The sections which go through the wall are packaged with the starter kit, and can be cut to suit if necessary.

20000584 | 17 |