Hearth

A hearth is not mandatory but is recommended for aesthetic purposes. We recommend a noncombustible hearth which projects out 12” (305 mm) or more from the front of the fireplace.

Cold climate installation recommendation: When installing this unit against a non- insulated exterior wall or chase, it is ![]() mandatory that the outer walls be insulated to conform to applicable insulation codes.

mandatory that the outer walls be insulated to conform to applicable insulation codes.

Framing and Finishing

Check fireplace to make sure it is levelled and properly positioned.

NOTE: If the optional Metro Face Kit (DVBR36 only) is to be installed, the fireplace may be placed on a 4” (102 mm) raised platform. Raising the fireplace will give the best aestethic appearance but is not required.

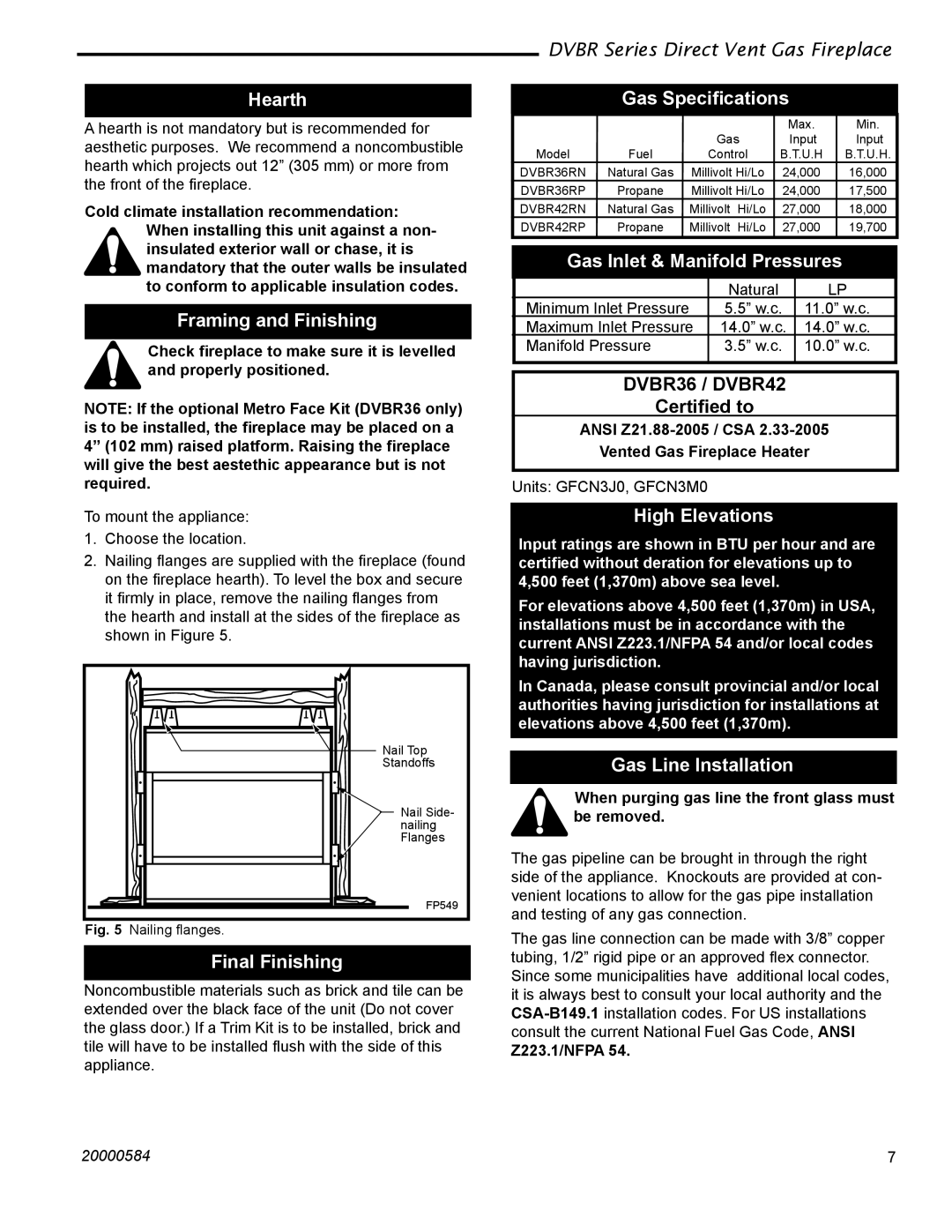

To mount the appliance:

1.Choose the location.

2.Nailing flanges are supplied with the fireplace (found on the fireplace hearth). To level the box and secure it firmly in place, remove the nailing flanges from the hearth and install at the sides of the fireplace as shown in Figure 5.

![]() Nail Top

Nail Top

Standoffs

Nail Side- nailing Flanges

FP549

Fig. 5 Nailing flanges.

Final Finishing

Noncombustible materials such as brick and tile can be extended over the black face of the unit (Do not cover the glass door.) If a Trim Kit is to be installed, brick and tile will have to be installed flush with the side of this appliance.

DVBR Series Direct Vent Gas Fireplace

Gas Specifications

|

|

| Max. | Min. |

|

| Gas | Input | Input |

Model | Fuel | Control | B.T.U.H | B.T.U.H. |

DVBR36RN | Natural Gas | Millivolt Hi/Lo | 24,000 | 16,000 |

DVBR36RP | Propane | Millivolt Hi/Lo | 24,000 | 17,500 |

DVBR42RN | Natural Gas | Millivolt Hi/Lo | 27,000 | 18,000 |

DVBR42RP | Propane | Millivolt Hi/Lo | 27,000 | 19,700 |

|

|

|

|

|

Gas Inlet & Manifold Pressures

| Natural | LP |

Minimum Inlet Pressure | 5.5” w.c. | 11.0” w.c. |

Maximum Inlet Pressure | 14.0” w.c. | 14.0” w.c. |

Manifold Pressure | 3.5” w.c. | 10.0” w.c. |

|

|

|

DVBR36 / DVBR42

Certified to

ANSI

Vented Gas Fireplace Heater

Units: GFCN3J0, GFCN3M0

High Elevations

Input ratings are shown in BTU per hour and are certified without deration for elevations up to 4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA, installations must be in accordance with the current ANSI Z223.1/NFPA 54 and/or local codes having jurisdiction.

In Canada, please consult provincial and/or local authorities having jurisdiction for installations at elevations above 4,500 feet (1,370m).

Gas Line Installation

When purging gas line the front glass must be removed.

The gas pipeline can be brought in through the right side of the appliance. Knockouts are provided at con- venient locations to allow for the gas pipe installation and testing of any gas connection.

The gas line connection can be made with 3/8” copper tubing, 1/2” rigid pipe or an approved flex connector. Since some municipalities have additional local codes, it is always best to consult your local authority and the

Z223.1/NFPA 54.

20000584 | 7 |