Radiance Direct Vent Gas Heater

from traffic areas such as walkways if it is less than 7’ (2.1 m) high. Refer to Pages 10, 11, Figures 11, 12 for more detail.

Snorkel Termination

Window Well

| 12” (305 mm) Minimum | |

Maintain 2” | Clearance Above Grade Level to | |

(51 mm) | Air Intake | |

Clearance | Grade Level | |

Below Snorkel | ||

Sloped Away | ||

| ||

| From Building | |

Adequate |

|

Wall

Thimble

Shield

Wall![]()

Thimble

Face

Plate

Wall Thimble Shield

Seal with RTV Silicone Sealant on Exterior side here (around perimeter)

![]() Wall Thimble

Wall Thimble

Face Plate

ST930

Drainage as per |

Local Codes |

ST929 |

Fig. 40 Below grade installation.

2.Assemble the pipe (and elbow if using) and attach it to the appliance. Plan for a level to 1/4” per foot rise (6 mm per 305 mm) (from inlet to outlet) in the horizontal system if not specified by the appliance manufacturer. Horizontal runs should be supported every 4’ (122 cm).

3.Push the appliance near the desired location. Deter- mine the centerpoint of the penetration by locating the centerline of the outlet of the pipe with respect to the wall.

4.Frame an opening to the dimension specified in the Framing Dimension Table 1. Ensure the centerline of the pipe lines up with the center of the prepared open- ing unless otherwise specified by the appliance manu- facturer.

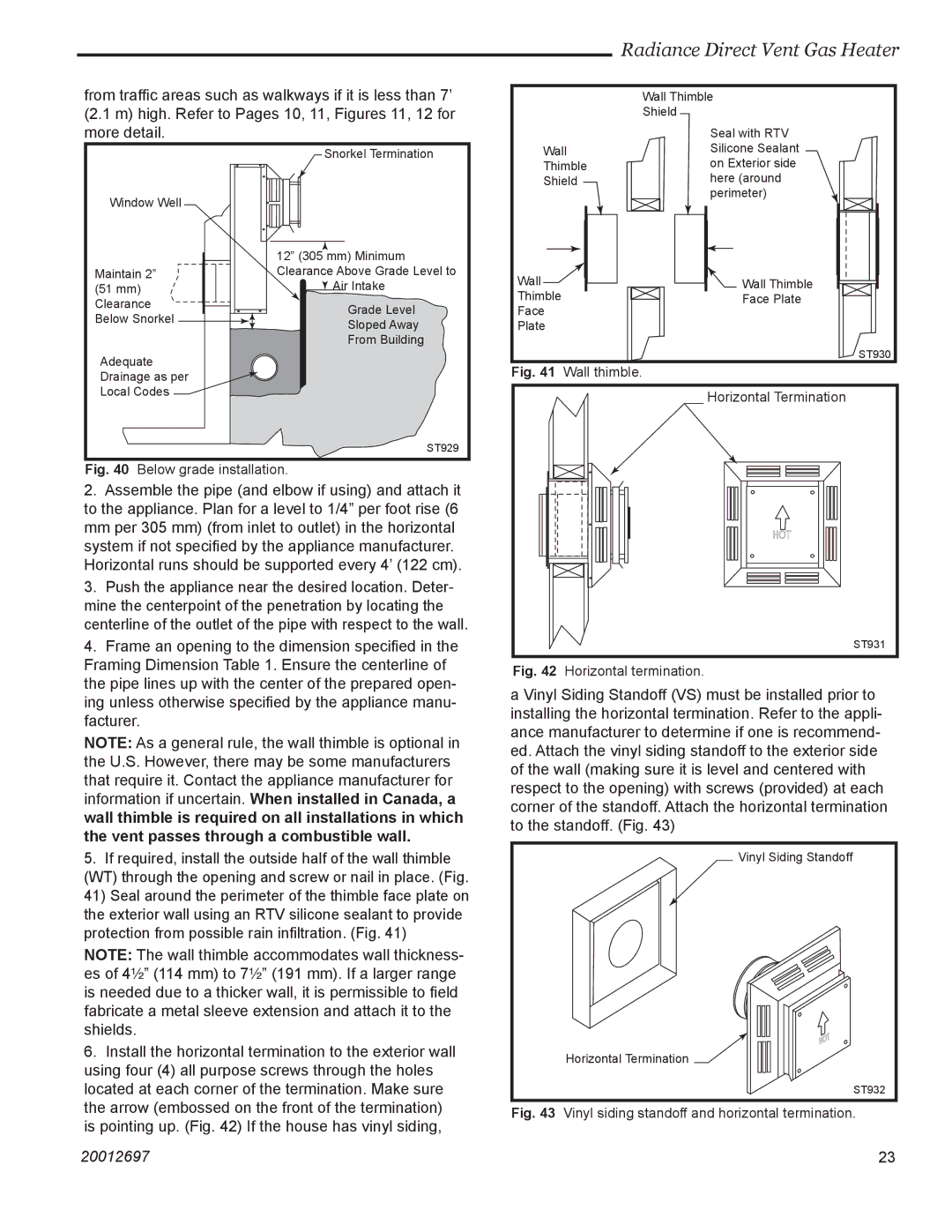

NOTE: As a general rule, the wall thimble is optional in the U.S. However, there may be some manufacturers that require it. Contact the appliance manufacturer for information if uncertain. When installed in Canada, a wall thimble is required on all installations in which the vent passes through a combustible wall.

5.If required, install the outside half of the wall thimble (WT) through the opening and screw or nail in place. (Fig. 41) Seal around the perimeter of the thimble face plate on the exterior wall using an RTV silicone sealant to provide protection from possible rain infiltration. (Fig. 41)

NOTE: The wall thimble accommodates wall thickness- es of 4¹⁄₂” (114 mm) to 7¹⁄₂” (191 mm). If a larger range is needed due to a thicker wall, it is permissible to field fabricate a metal sleeve extension and attach it to the shields.

6.Install the horizontal termination to the exterior wall using four (4) all purpose screws through the holes located at each corner of the termination. Make sure the arrow (embossed on the front of the termination) is pointing up. (Fig. 42) If the house has vinyl siding,

Fig. 41 Wall thimble.

Horizontal Termination

ST931

Fig. 42 Horizontal termination.

a Vinyl Siding Standoff (VS) must be installed prior to installing the horizontal termination. Refer to the appli- ance manufacturer to determine if one is recommend- ed. Attach the vinyl siding standoff to the exterior side of the wall (making sure it is level and centered with respect to the opening) with screws (provided) at each corner of the standoff. Attach the horizontal termination to the standoff. (Fig. 43)

Vinyl Siding Standoff

Horizontal Termination ![]()

ST932

Fig. 43 Vinyl siding standoff and horizontal termination.

20012697 | 23 |