Radiance Direct Vent Gas Heater

Vertical Termination

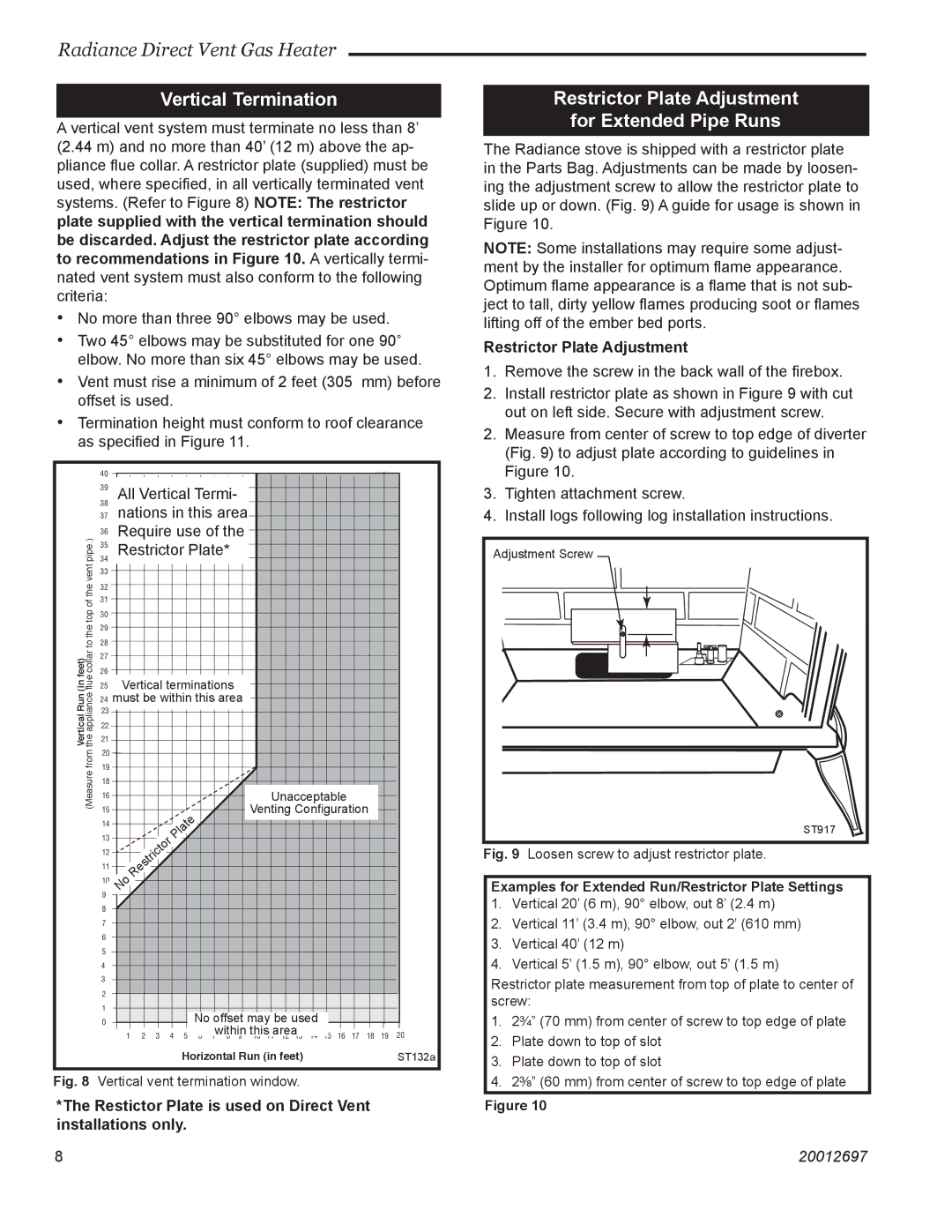

A vertical vent system must terminate no less than 8’ (2.44 m) and no more than 40’ (12 m) above the ap- pliance flue collar. A restrictor plate (supplied) must be used, where specified, in all vertically terminated vent systems. (Refer to Figure 8) NOTE: The restrictor plate supplied with the vertical termination should be discarded. Adjust the restrictor plate according to recommendations in Figure 10. A vertically termi- nated vent system must also conform to the following criteria:

•No more than three 90° elbows may be used.

•Two 45° elbows may be substituted for one 90˚ elbow. No more than six 45° elbows may be used.

•Vent must rise a minimum of 2 feet (305 mm) before offset is used.

•Termination height must conform to roof clearance as specified in Figure 11.

��

| �� | All Vertical Termi- |

| �� | nations in this area |

| �� | |

pipe.) | �� | Require use of the |

���� | Restrictor Plate* | |

vent | �� |

|

the | �� |

|

�� |

| |

of |

| |

|

| |

top | �� |

|

|

| |

to the | �� |

|

�� |

| |

collar | �� |

|

feet) | �� |

|

flue |

| |

�� |

| |

(in |

| Vertical terminations |

appliance | �� | must be within this area |

|

| |

Run | �� |

|

Vertical the |

| |

�� |

| |

|

| |

| �� |

|

from | �� |

|

�� |

| |

(Measure |

| |

�� |

| |

|

| |

| �� | Unacceptable |

| �� | Venting Configuration |

| �� |

|

| �� |

|

| �� |

|

| �� |

|

�

�

�

�

�

���

���

�

�

� |

| No offset may be used |

|

|

|

| within this area |

|

|

| � | �� �� �� �� �� | ||

| � � � � | |||

|

| Horizontal Run (in feet) |

| ST132a |

Fig. 8 Vertical vent termination window.

*The Restictor Plate is used on Direct Vent installations only.

Restrictor Plate Adjustment

for Extended Pipe Runs

The Radiance stove is shipped with a restrictor plate in the Parts Bag. Adjustments can be made by loosen- ing the adjustment screw to allow the restrictor plate to slide up or down. (Fig. 9) A guide for usage is shown in Figure 10.

NOTE: Some installations may require some adjust- ment by the installer for optimum flame appearance. Optimum flame appearance is a flame that is not sub- ject to tall, dirty yellow flames producing soot or flames lifting off of the ember bed ports.

Restrictor Plate Adjustment

1.Remove the screw in the back wall of the firebox.

2.Install restrictor plate as shown in Figure 9 with cut out on left side. Secure with adjustment screw.

2.Measure from center of screw to top edge of diverter (Fig. 9) to adjust plate according to guidelines in Figure 10.

3.Tighten attachment screw.

4.Install logs following log installation instructions.

Adjustment![]() Screw

Screw

ST917

Fig. 9 Loosen screw to adjust restrictor plate.

Examples for Extended Run/Restrictor Plate Settings

1.Vertical 20’ (6 m), 90° elbow, out 8’ (2.4 m)

2.Vertical 11’ (3.4 m), 90° elbow, out 2’ (610 mm)

3.Vertical 40’ (12 m)

4.Vertical 5’ (1.5 m), 90° elbow, out 5’ (1.5 m)

Restrictor plate measurement from top of plate to center of screw:

1.2³⁄₄” (70 mm) from center of screw to top edge of plate

2.Plate down to top of slot

3.Plate down to top of slot

4.2³⁄₈” (60 mm) from center of screw to top edge of plate

Figure 10

88 | 20012697 |