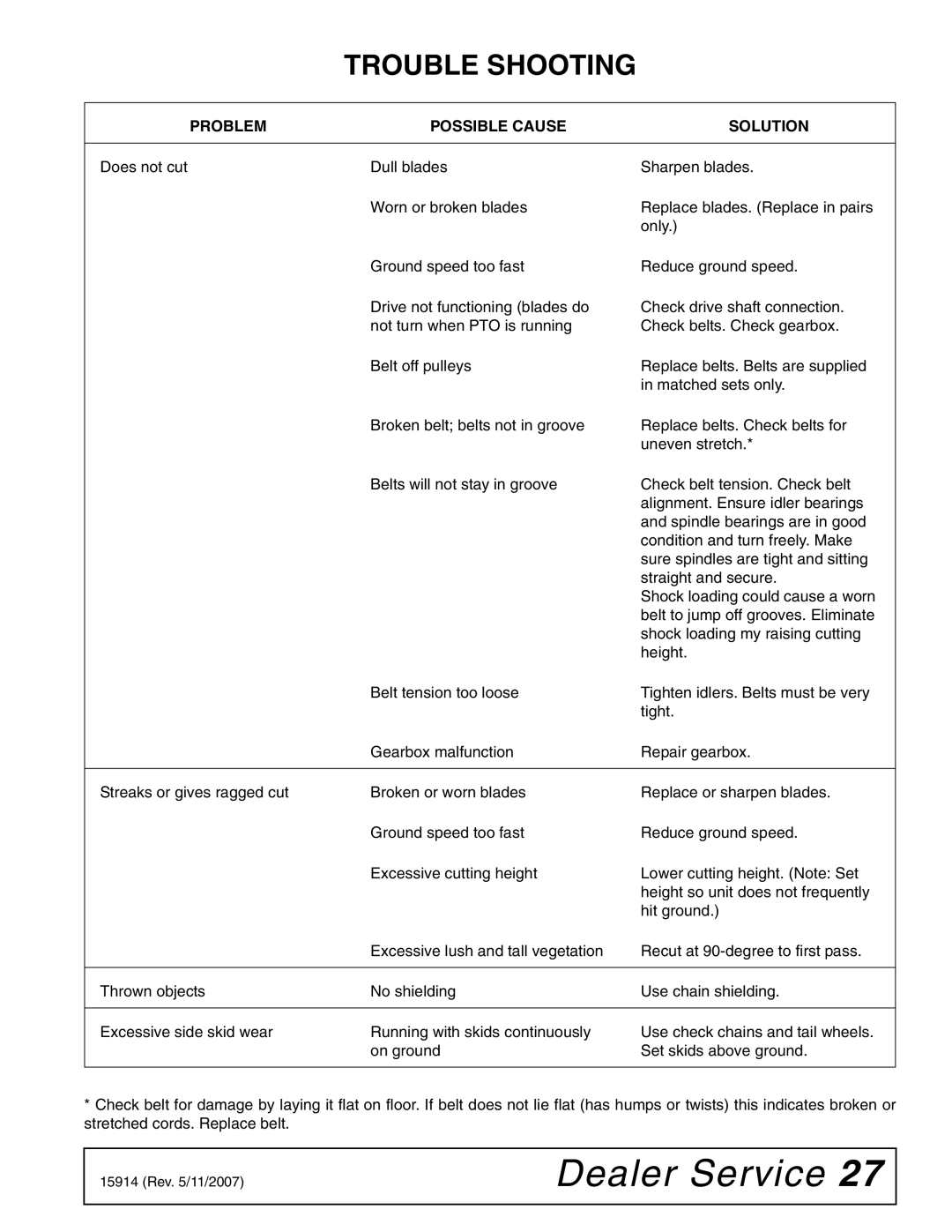

TROUBLE SHOOTING

PROBLEM | POSSIBLE CAUSE | SOLUTION |

|

|

|

Does not cut | Dull blades | Sharpen blades. |

| Worn or broken blades | Replace blades. (Replace in pairs |

|

| only.) |

| Ground speed too fast | Reduce ground speed. |

| Drive not functioning (blades do | Check drive shaft connection. |

| not turn when PTO is running | Check belts. Check gearbox. |

| Belt off pulleys | Replace belts. Belts are supplied |

|

| in matched sets only. |

| Broken belt; belts not in groove | Replace belts. Check belts for |

|

| uneven stretch.* |

| Belts will not stay in groove | Check belt tension. Check belt |

|

| alignment. Ensure idler bearings |

|

| and spindle bearings are in good |

|

| condition and turn freely. Make |

|

| sure spindles are tight and sitting |

|

| straight and secure. |

|

| Shock loading could cause a worn |

|

| belt to jump off grooves. Eliminate |

|

| shock loading my raising cutting |

|

| height. |

| Belt tension too loose | Tighten idlers. Belts must be very |

|

| tight. |

| Gearbox malfunction | Repair gearbox. |

|

|

|

Streaks or gives ragged cut | Broken or worn blades | Replace or sharpen blades. |

| Ground speed too fast | Reduce ground speed. |

| Excessive cutting height | Lower cutting height. (Note: Set |

|

| height so unit does not frequently |

|

| hit ground.) |

| Excessive lush and tall vegetation | Recut at |

|

|

|

Thrown objects | No shielding | Use chain shielding. |

|

|

|

Excessive side skid wear | Running with skids continuously | Use check chains and tail wheels. |

| on ground | Set skids above ground. |

|

|

|

*Check belt for damage by laying it flat on floor. If belt does not lie flat (has humps or twists) this indicates broken or stretched cords. Replace belt.

15914 (Rev. 5/11/2007) | Dealer Service 27 |

|

|