W1754 20" Planer With Mobile Base

Lubrication

This planer uses sealed and

The following is a list of parts that need lubrication:

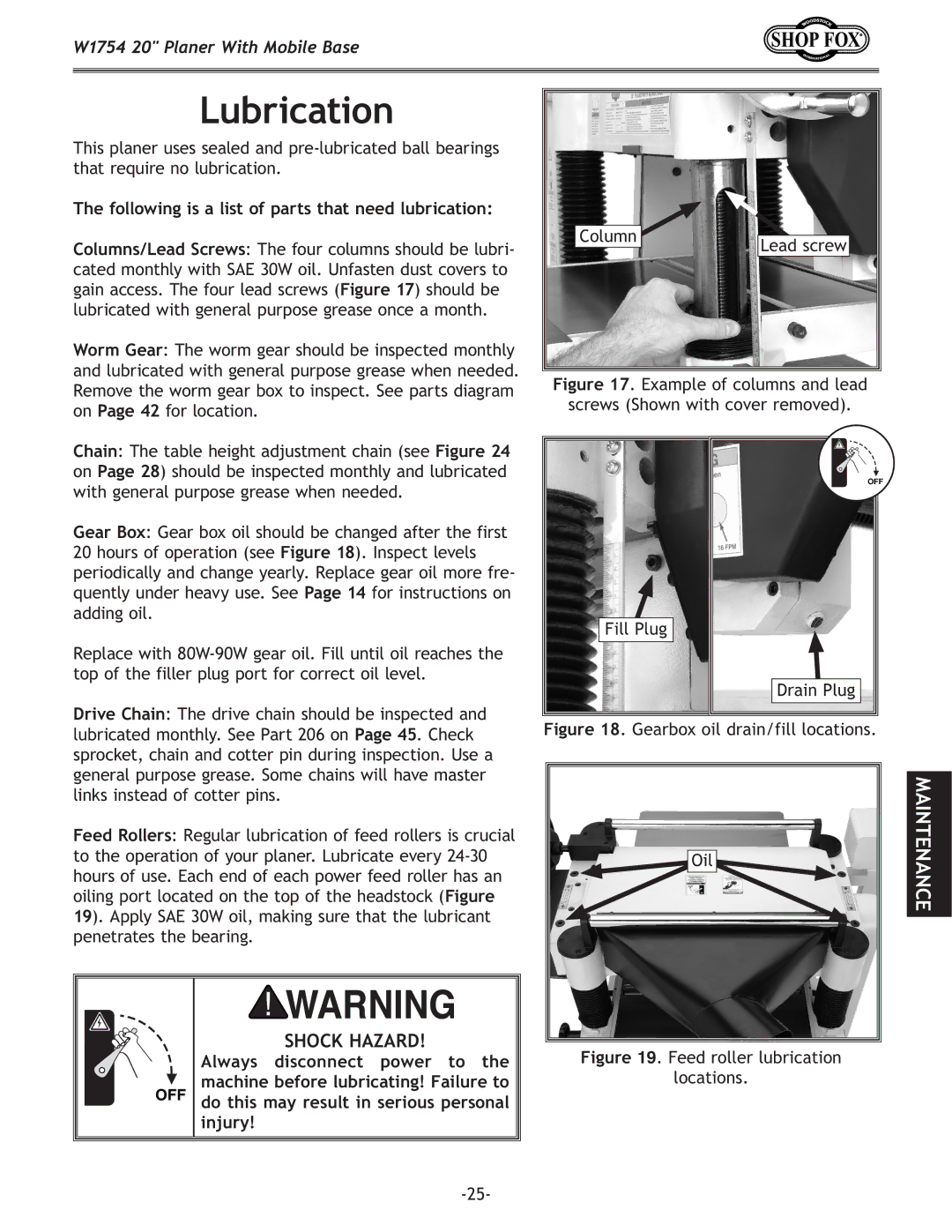

Columns/Lead Screws: The four columns should be lubri- cated monthly with SAE 30W oil. Unfasten dust covers to gain access. The four lead screws (Figure 17) should be lubricated with general purpose grease once a month.

Worm Gear: The worm gear should be inspected monthly and lubricated with general purpose grease when needed. Remove the worm gear box to inspect. See parts diagram on Page 42 for location.

Chain: The table height adjustment chain (see Figure 24 on Page 28) should be inspected monthly and lubricated with general purpose grease when needed.

Gear Box: Gear box oil should be changed after the first 20 hours of operation (see Figure 18). Inspect levels periodically and change yearly. Replace gear oil more fre- quently under heavy use. See Page 14 for instructions on adding oil.

Replace with

Drive Chain: The drive chain should be inspected and lubricated monthly. See Part 206 on Page 45. Check sprocket, chain and cotter pin during inspection. Use a general purpose grease. Some chains will have master links instead of cotter pins.

Feed Rollers: Regular lubrication of feed rollers is crucial to the operation of your planer. Lubricate every

| SHOCK HAZARD! |

| |

| Always disconnect power to the |

OFF | machine before lubricating! Failure to |

do this may result in serious personal | |

| injury! |

|

|

|

Column | Lead screw |

|

Figure 17. Example of columns and lead screws (Shown with cover removed).

OFF

Fill Plug

Drain Plug

Figure 18. Gearbox oil drain/fill locations.

Oil | MAINTENANCE |

|