Xantrex AC to DC Converter

Mounting the XADC and Panel Remotely

To mount the XADC and panel remotely:

1.Slide the panel into the mounting cutout (12 in. × 8 in. – 305 mm × 203 mm).

2.Fasten the panel to the mounting surface using 6 × #6 or #8 pan head, round head or washer head screws suitable for mounting the panel onto particleboard or wood.

3.Install the panel faceplate and tighten the center screw (do not overtighten as this may cause stripping of the screw threads).

4.Install the DC fuse cover.

5.Follow the instructions in “Mounting the XADC” on page 15 to mount the XADC.

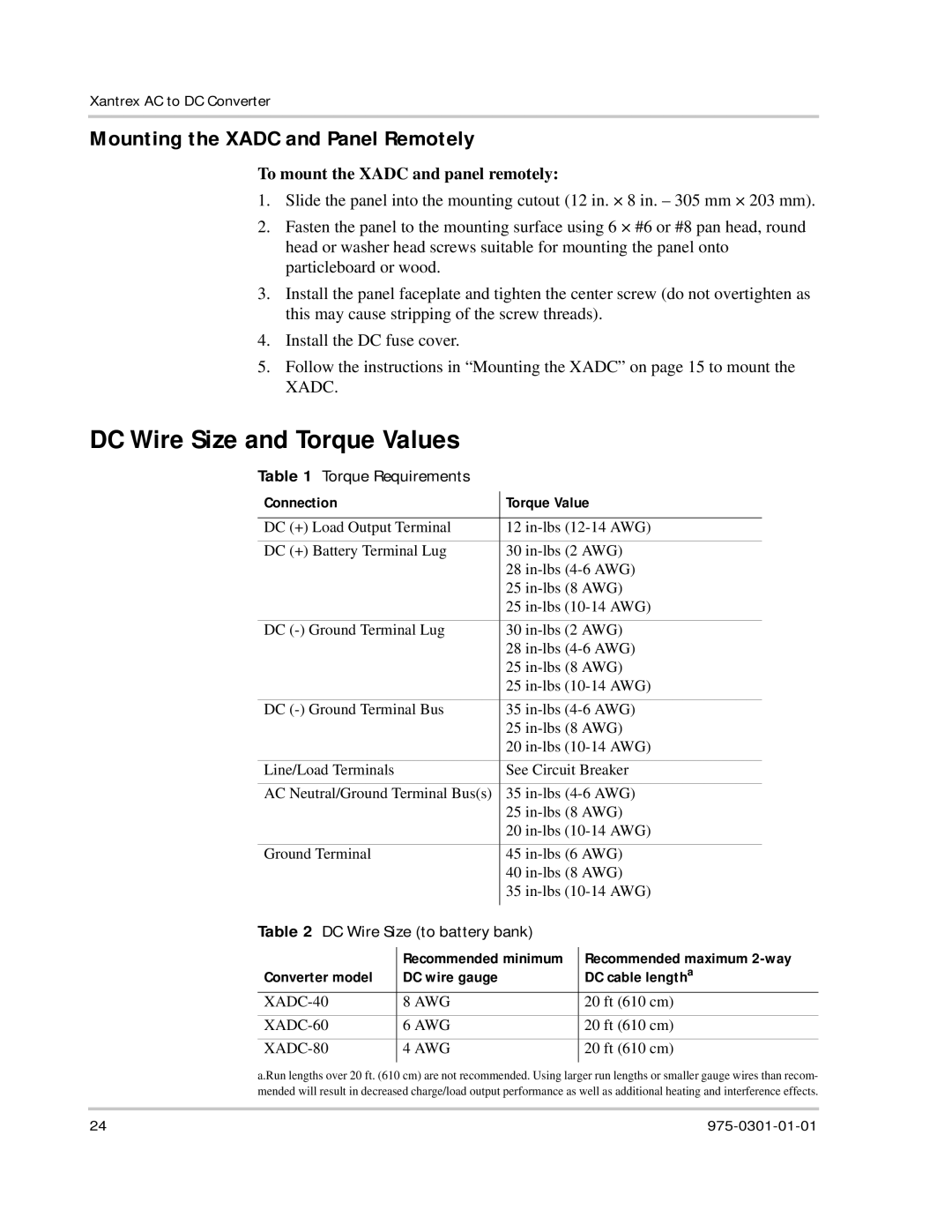

DC Wire Size and Torque Values

Table 1 Torque Requirements

Connection | Torque Value |

|

|

DC (+) Load Output Terminal | 12 |

DC (+) Battery Terminal Lug | 30 |

| 28 |

| 25 |

| 25 |

DC | 30 |

| 28 |

| 25 |

| 25 |

DC | 35 |

| 25 |

| 20 |

Line/Load Terminals | See Circuit Breaker |

AC Neutral/Ground Terminal Bus(s) | 35 |

| 25 |

| 20 |

Ground Terminal | 45 |

| 40 |

| 35 |

|

|

Table 2 DC Wire Size (to battery bank)

| Recommended minimum | Recommended maximum |

Converter model | DC wire gauge | DC cable lengtha |

8 AWG | 20 ft (610 cm) | |

6 AWG | 20 ft (610 cm) | |

4 AWG | 20 ft (610 cm) | |

|

|

|

a.Run lengths over 20 ft. (610 cm) are not recommended. Using larger run lengths or smaller gauge wires than recom- mended will result in decreased charge/load output performance as well as additional heating and interference effects.

24 |