Operator’s Manual

Corporate Headquarters

4501 Parkway Commerce Blvd Orlando, Fl Phone:

Fax:

Page

Copyright Information

Firmware Software Agreement

Agency Compliance and Approvals

C22.2 No. 950-M93

EN60950

C US Listed

Page

Important Safety Instructions

Contents

Setting Up the Printer

Printer Overview

Getting Started

Using the Front Panel

Adjusting and Maintaining the Printer

Troubleshooting

Printer Specifications

Appendix A

Appendix B

Appendix E

Appendix F

Menu System Multi-LanguageSupport

Glossary

Printer Overview

1.0About the Printer

1.0.1Standard Features

Cutter, Light-Duty Backing-Only

Cutter, Standard Duty

I-ClassStandard Features Listing

DMXNet

Internal Rewinder

ILPC – CG Times Firmware

Linear Scanner

Present Sensor

RS-422Serial Interface

Twinax/Coax Interface

USB Port

1.1 Option Installation

Experience Level for Options Installation

Recommended Installer

Option

1.2Hardware Components

I-Class

I-Class

Getting Started

2.0Unpacking the Printer

2.0.1Inspection

2.0.2Additional Requirements

2.1Media and Ribbon Selection

2.1.1Print Quality Controls

Media Selection – Direct Thermal

Media Selection – Thermal Transfer

Direct Thermal Media Type

Print Speed

Print Energy

Thermal Transfer

Setting Up the Printer

3.0Installation

Parallel Port

3.0.1Communications

Serial Port

Null Modem MXM

“PC” DB9P to Printer

Part Number

Part Number

USB Port optional

3.1Loading Media

3.1.1Roll Media

3.1.2Fan-FoldMedia

3.2Media Sensor Adjustment

Media Sensor Selection and Adjustment

Media Type

Sensor Eye Mark Position

3.3Loading Ribbon

Removal

Ribbon Routing Diagrams

‘Coating Side In’ Ribbon Supply Hub

‘Coating Side Out’ Ribbon Supply Hub

I-Class

3.4Quick Media Calibration

Calibration Hints

3.5Outputting Labels

3.5.1Rewinding

Removal

I-Class

3.5.2On-DemandDispensing

Removal

I-Class

3.5.3Cutting

Using the Front Panel

4.0Operation

I-Class

4.0.3Quick Test Mode: Print Test Labels

4.0.5LCD

4.0.4Indicator Lights

ŒLiquid Crystal Display

4.0.6Resetting the Printer

4.0.6.1Soft Reset

4.0.6.2Level One Reset

4.0.6.3Level Two Reset

4.1The Menu System

4.1.1Entrance and Exit Prompts

MENU MODE

4.1.2Media Settings

MEDIA TYPE

SENSOR TYPE

LABEL LENGTH

4.1.3Print Control

HEAT

PRINT SPEED

FEED SPEED

CUSTOM ADJUSTMENTS

Print Control continued

MODULES

4.1.4Printer Options

PRESENT SENSOR

CUTTER

Printer Options continued

SCANNER

Printer Options continued

Used to set the specific number of barcodes

Printer Options continued

GPIO PORT

4.1.5System Settings

CONFIGURATION FILE

DEFAULT MODULE

SINGLE BYTE SYMBOLS

System Settings continued

DOUBLE BYTE SYMBOLS

PRINT CONFIGURATION

TIME AND DATE

System Settings continued

CONFIGURATION LEVEL

System Settings continued

SET FACTORY DEFAULTS

FORMAT ATTRIBUTES

IMAGING MODE

System Settings continued

PAUSE MODE

PEEL MODE

SECURITY

System Settings continued

PLUS EMULATION

System Settings continued

ALLEGRO EMULATION

DPI EMULATION

DPI EMULATION

System Settings continued

COLUMN EMULATION

SOP EMULATION

BACK AFTER PRINT

FAULT HANDLING

System Settings continued

MENU LANGUAGE

System Settings continued

The distance to backup on the defective

SERIAL PORT A

4.1.6Communications

SERIAL PORT B

Communications continued

PARALLEL PORT A

PARALLEL PORT B

NIC ADAPTER

Communications continued

Specifies the network gateway address the

HOST SETTINGS

Communications continued

Allows the user to disable the DPL Heat

Communications continued

4.1.7 Diagnostics

OPTIONS TESTING

HEX DUMP MODE

PRINT TEST RATE

SENSOR READINGS

Diagnostics continued

RIBBON SENSOR LIMITS

4.2Display Messages

4.2.1User Prompts and Condition Messages

User Prompts and Condition Messages

Displayed Message

User Prompts and Condition Messages continued

Displayed Message

Description

Conditions

4.3Quick Test Mode

4.3.1Print Quality Label

4.3.2Configuration Label

4.3.3Quick Ribbon Test Label

ΠPress the

•Use the Key to scroll to ‘Ribbon Test Label’

ŽUse the Key to select a quantity; see Section

4.3.4Dot Test Pattern Label

4.3.5Validation Label

4.3.6User Defined Label

Adjusting and Maintaining the Printer

5.0Media Sensor Calibration

5.0.1Standard Calibration

Step

Standard Calibration continued

Step

Operator Action

Displayed Message

Notched stock: adjust

Reflective stock: Adjust

Standard Calibration continued

Step

Standard Calibration continued

Step

Operator Action

Displayed Message

5.0.2Advanced Entry Calibration

Step

Operator Action

Displayed Message

Advanced Entry Calibration continued

Step

Operator Action

Displayed Message

Notched stock: adjust

Reflective stock: Adjust

Advanced Entry Calibration continued

Step

Advanced Entry Calibration continued

Step

Operator Action

Displayed Message

Advanced Entry Calibration continued

Step

Operator Action

Displayed Message

Advanced Entry Calibration continued

Step

Operator Action

Displayed Message

5.1Printhead Adjustments

5.1.1Leveling Cam Adjustment

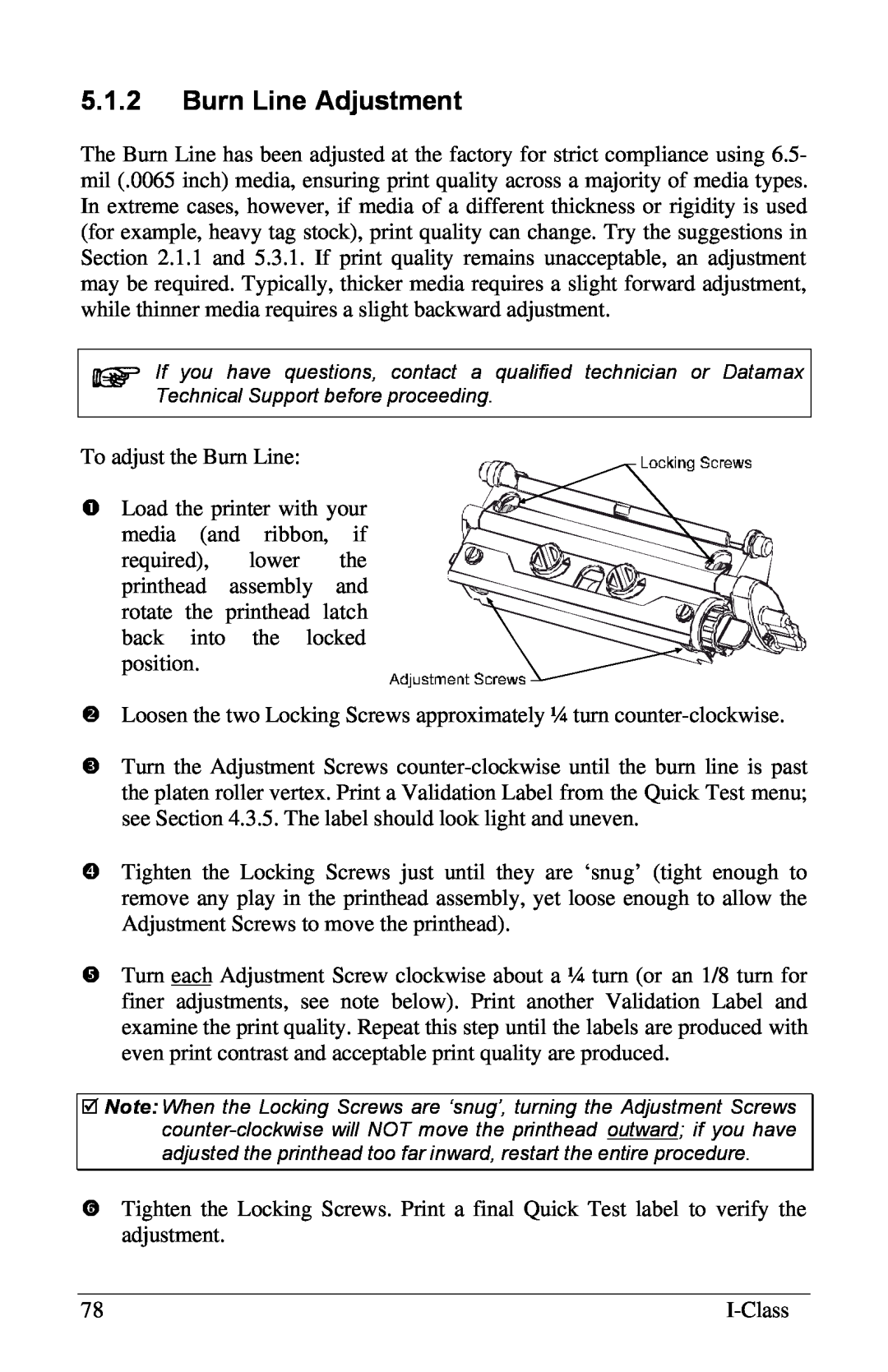

5.1.2Burn Line Adjustment

5.2Printhead Replacement

5.3Maintenance Schedule

Recommended Cleaning Schedule

Area

Method

5.3.1Cleaning the Printhead

5.3.2Cleaning the Platen Roller

5.4Application Program Updates

5.3.3Cleaning Interior and Exterior Surfaces

5.4.1Updating from the Ready Mode

Step

Displayed Message

Operator Action

5.4.2Updating from the Download Mode

Step

Displayed Message

Operator Action

5.4.3Possible Problems during an Update

Application Update Error Messages

Descriptions / Causes / Solutions

Displayed Message

5.5Boot Loader Program Updates

Boot Loader Update Procedure

Step

Displayed Message

I-Class

Troubleshooting

6.0Problem Resolution

If experiencing this problem…

Try this solution…

Try this solution…

If experiencing this problem…

Erratic printing instead of the

If experiencing this problem…

Try this solution…

If there is an image on the used ribbon

If there is no image on the used ribbon

If experiencing this problem…

Try this solution…

Nothing happens when trying

the I & W Class Programmer’s Manual for

6.1Fault and Warning Messages

Fault Messages

Printer Fault Messages

Possible Solutions

Printer Fault Messages continued

Possible Solutions

Displayed Message

Description

Printer Fault Messages continued

Possible Solutions

Displayed Message

Description

Printer Fault Messages continued

Possible Solutions

Displayed Message

Description

Printer Fault Messages continued

Possible Solutions

Displayed Message

Description

Printer Fault Messages continued

Possible Solutions

Displayed Message

Description

Warning Messages

Printer Fault Messages continued

Possible Solutions

Displayed Message

Printer Warning Messages

Displayed Message

Description

Actions

6.2Hex Dump Mode

I-Class

Printer Specifications

7.0General Specifications

Bar Codes

Fonts

Printing Specifications

Environmental Requirements

Mechanical

I-4208,

7.1Media and Ribbon Requirements

Printing Specifications continued

I-4212, I–4308

1 MB I-4206,

Approved Media

Media Dimensions

Media and Ribbon Requirements continued

Designator

ASCII Control Code Chart

Appendix A

Char

Char

ASCII Control Code Chart continued

Char

Char

Char

Appendix B

Available Fonts and Bar Codes

Fonts

Font

Font

Height

Width

Spacing

Font 4: 62-characteralphanumeric

Font 5: 62-characteralphanumeric

uppercase

uppercase

Font 8: OCR-B,size

Font 7: OCR-A,size

I-Class

Bar Code Summary Data

I-Class

Bar Code A: Code Bar Code C: UPC-E

Bar Code E: Code Bar Code G: EAN-8

Bar Code I: Codabar

Bar Code B: UPC-A

Bar Code K: Plessey

Bar Code M: 2 Digit UPC addendum

Bar Code O Code

Bar Code Q: UCC/EAN Code

Bar Code W1c: DataMatrix Bar Code W1f: Aztec

Bar Code T: Telepen Bar Code v: FIM

Bar Code WG: USD-8 Bar Code W1d: QR Code

Bar Code W1z: MicroPDF417

Print Resolutions and Maximum Label Widths

Appendix C

Module Assignments

Resolutions and Widths

Available Speeds and Default Settings

Printer Speed Ranges and Defaults

Default Setting

Speed Range

Appendix D

GPIO Port Description

GPIO Port Connections

Signal

GPIO Port Specifications

GPIO Pin Configuration

External Start of Print Control

Appendix E

Menu System Multi-LanguageSupport

Required Software

Comment

Creating a Menu Language

I-Class

I-Class

Menu Language Error Message

Advance File Handling Information

Description

I-Class

I-Class

Saving a Configuration File

Appendix F

Step

Displayed Message

Operator Action

Comments

Warranty Information

Printer

Limited Warranty Statement I-Class Printers

When returned to the factory for service

Thermal Printhead, Platen Roller, and Belts

Warranty Service Procedures

When returned to the factory for service

General Warranty Provisions

Limitation of Liability

I-Class

Glossary

fan-fold Media that is folded and stacked

I-Class

I-Class