1 |

Data Sent by the Master

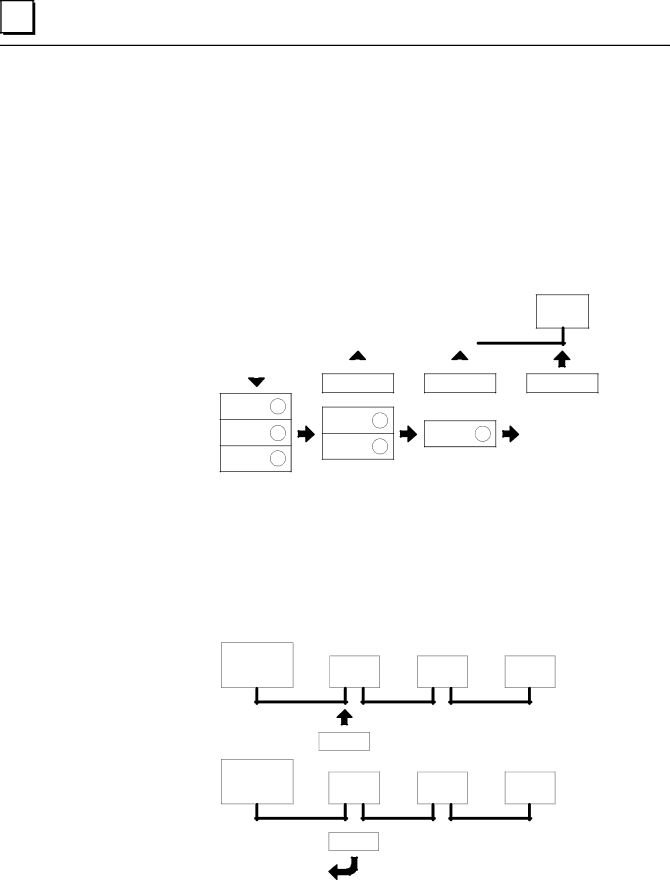

The master sends output data for all slave devices together. If a Series 90±70 PLC is the master on an I/O Link, it simply places the data to be sent into the %Q output references assigned to the I/O Link Interface Module.

Slaves receive the data in order of their positions on the link. Each slave in turn reads out its configured amount of data, and passes the remainder on to the next slave. To a slave, data received from the master is input data. If a Series 90±70 PLC is a slave, it obtains the data received from the master by reading the %I input references assigned to the I/O Link Interface Module.

MASTER |

|

|

|

|

|

|

|

| |

| SLAVE |

| SLAVE | ||||||

|

|

| 1 |

|

| 2 |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INPUTS | INPUTS |

OUTPUTS | 1 |

|

| OUTPUTS | 2 |

OUTPUTS | 2 | OUTPUTS 3 |

| OUTPUTS | 3 |

OUTPUTS | 3 |

|

a45009

SLAVE

3

INPUTS

Data Returned by Slaves

The master continuously reads the output data from each slave. If a Series 90±70 PLC is a slave, it provides this data by placing it into the %Q references configured for the I/O Link Interface Module. If a Series 90±70 PLC is the master, it reads the data from the %I references assigned to the I/O Link Interface Module.

MASTER

SLAVE

1

SLAVE

2

a45004

SLAVE

3

INPUTS

MASTER

SLAVE

1

SLAVE

2

SLAVE

3

OUTPUTS

The master identifies each set of data it receives with respect to the slave's position on the link. To the master, data received from slaves is input data.

10 | Series |