Return Air

The return air ductwork may be connected to any or all of the following: left side return, right side return, or bottom return. Tables 1 and 2 show the airflow data for each furnace model. Where maximum airflow is 1800 CFM or more two openings must be used.

VENTING AND COMBUSTION AIR REQUIREMENTS

NORDYNE condensing furnaces may be installed with outdoor combustion air piped directly to the furnace, or without such special piping. Codes refer to the former as “direct vent” or “two pipe” installation. Installation with air taken from around the furnace is sometimes referred to as “one pipe” installation where only the vent (exhaust) pipe is provided.

Provisions must be made for adequate sup- ply of air for combustion and ventilation. For United States installations, the adequacy of air provisions can be determined by consulting the current version of the National Fuel Gas Code (ANSI

An important consideration in selecting one or two pipe installation is the quality of the combus- tion air. Indoor air is sometimes contaminated with various household chemicals which can cause severe corrosion in the furnace combus- tion system.

NOTE: If the furnace is operated without ade- quate air for combustion and ventilation, it may not perform properly. Furnace components may be strained by high temperature and could fail .

!WARNING:

Furnace installation using methods other than those described in the fol- lowing sections must comply with the National Fuel Gas Code and all appli- cable local codes to provide sufficient combustion air for the furnace.

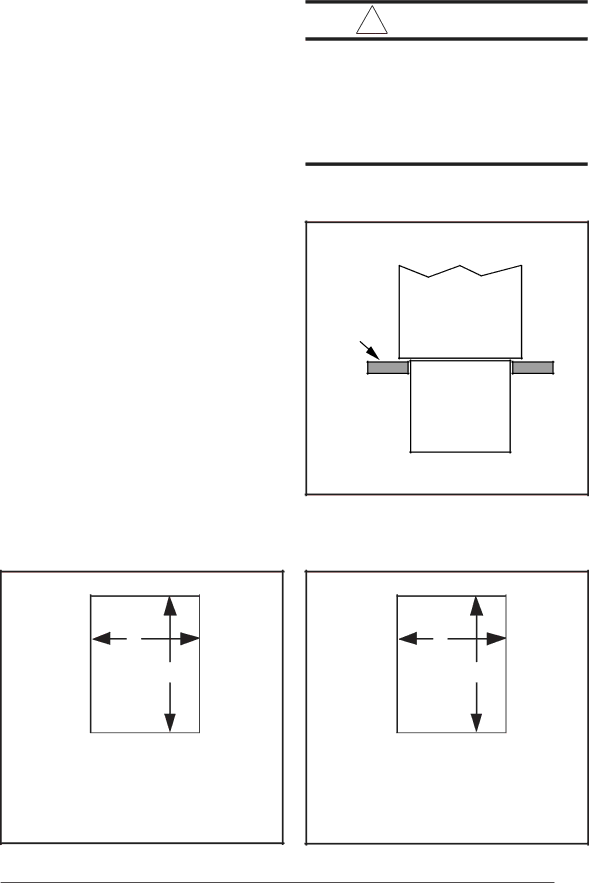

Concrete | Furnace |

Floor |

|

| Sheet |

| Metal |

| Plenum |

Figure 6. Furnace on a Concrete Slab

A |

B |

MODEL | A | B |

|

|

|

*RL 040/060 | 13.25” | 19.25” |

|

|

|

*RL 080/100 | 18.75” | 19.25” |

|

|

|

*RL 120 | 21.50” | 19.25” |

|

|

|

Figure 5. Opening for Concrete Slab

A |

B |

MODEL | A | B | |

|

|

|

|

*RL 040/060 | 13.25” | 19.63” | |

|

|

|

|

*RL 080/100 | 18.75” | 19.63” | |

|

|

| |

*RL 120 | 21.50” | 19.63” | |

Figure 7. Opening in Wood Floor

13