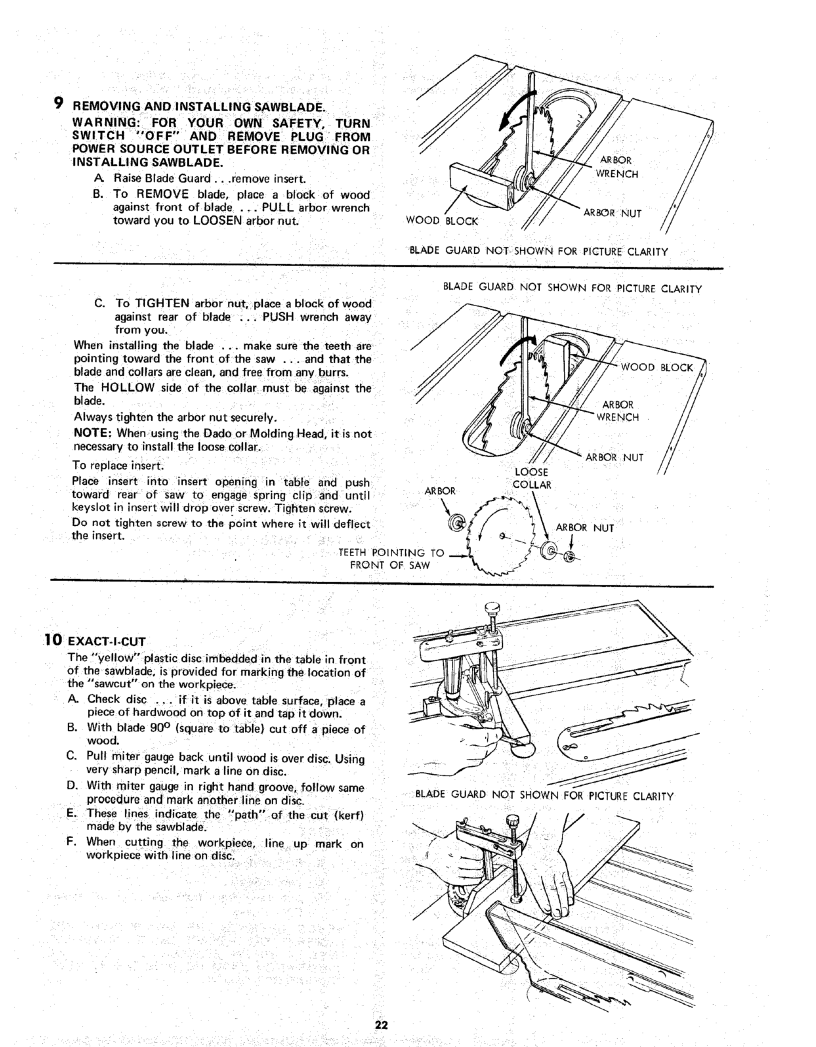

9 REMOVING AND INSTALLING SAWBLADE.

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE REMOVING OR INSTAL LING SAWBLADE.

A. Raise Blade Guard...remove insert.

B. To REMOVE blade, place a block of wood against front of blade ... PULL arbor wrench toward you to LOOSEN arbor nut.

C.To TIGHTEN arbor nut, place a block of wood against rear of blade ;.. PUSH wrench away from you.

When installing the blade . .. make sure the teeth are pointing toward the front of the saw ... and that the blade and collars are clean, and free from any burrs.

The HOLLOW side of the collar must be against the blade.

Always tighten the arbor nut securely.

NOTE: When using the Dado or Molding Head, itis not necessary to install the loose collar.

To replace insert.

Place insert into insert opening n table and push

keyslot in insert will drop over screw. Tighten screw.

toward rear of saw to engage spring clip and unt, I

/

/ | OR NUT |

WOOD BLOCK

BLADE GUARD NOT SHOWN FOR PICTURE CLARITY

BLADE GUARD NOT SHOWN FOR PICTURE CLARITY

NUT

LOOSE

COLLAR

_,

AR,OR ff_,_

Do not tighten screw to the point where it will deflect(_"//_\ ARBORNUT

the insert, | rTEETHFO,NT,TO'. | __ | __ | |

• | FRONT OF SAW | h | _, | v |

1 0

The 'yellow" plastic disc imbedded n the table in front

of the sawb!ade, is provided for marking the location of the sawcut on the workpiece.

A.Check disc ... if it is above table surface, place a piece of hardwood on top of it and tap it down.

B.With blade 90 ° (square to table) cut off a piece of wood.

C.Pull miter gauge back until wood is over disc. Using very sharp pencil, mark a line on disc.

DWith miter gauge in right hand groove, follow same

procedure and mark another line on disc | BLADE GUARD NOT SHOWN FOR PICTURE CLARITY |

E. These I in es mdlcate" " the ""path "" of the cut (kerf) made by the sawblade.

F. When cutting the workpiece, ine up mark on workpiece with line on disc.

22