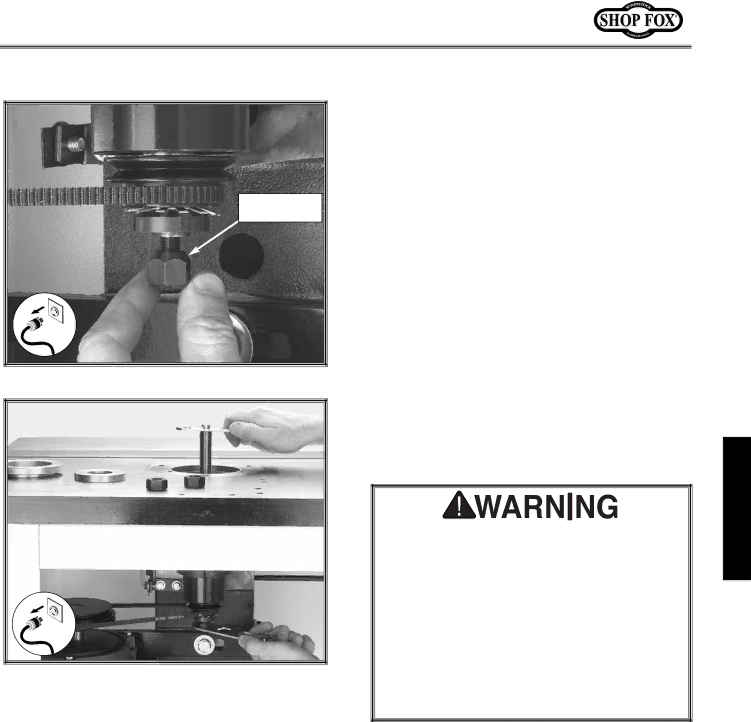

Drawbar Nut

Taper Side Up

Figure 20. Threading drawbar nut onto drawbar.

Figure 21. Tightening the drawbar nut onto the

end of the drawbar.

6.Thread the tapered drawbar nut onto the end of the drawbar under the table, and make sure that the taper side of the nut is facing upward as shown in Figure 20.

7.Tighten your selected spindle in the shaper as outlined below:

•For shaper spindles: Place the spindle wrench on the top end of the spindle. Using a 15mm

•For router bit spindles: Hold the router bit spindle flat on the

ONLY operate your shaper in the COUNTER- CLOCKWISE direction as looking downward at the spindle when when you use a router bit adapter. Router bits are designed to cut in the

ASSEMBLY