Table Inserts

The table inserts are necessary for the safe operation of the shaper. Two inserts are provided allowing for three different opening sizes to be achieved. Use the

To adjust the table inserts, do these steps:

1.UNPLUG THE SHAPER!

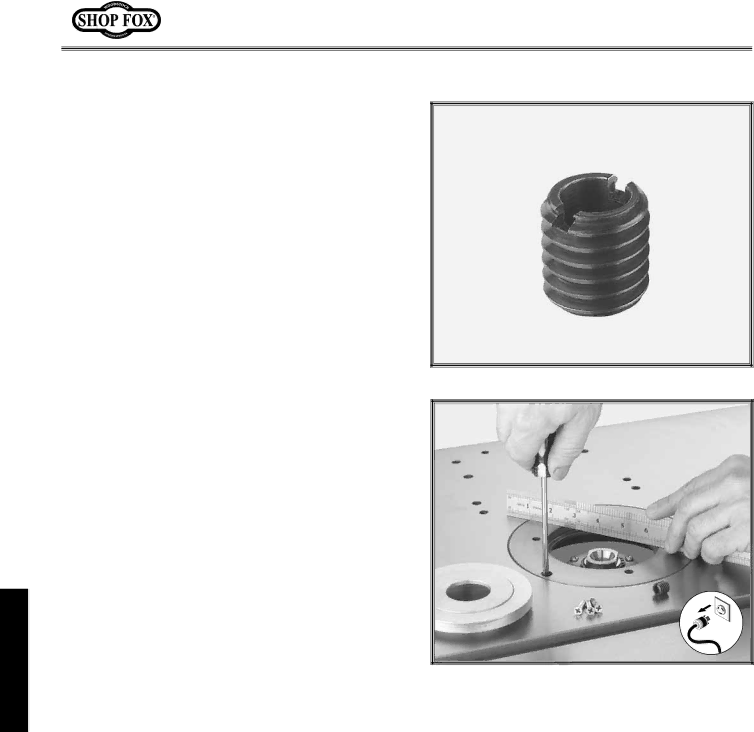

2.Using a screwdriver, remove the three Phillips® head screws holding the cast iron insert in the table. See Figure 25.

3.Using a straightedge as a guide, turn the

4.Once the entire insert is flush with the table top, reinsert the three Phillips® head screws and tighten.