Step 2. With the water heater plugged in and the gas control power switch in the “ON” position verify LED status.

Page 40

Verify 115VAC and proper polarity are at the wall outlet.

Step 1.

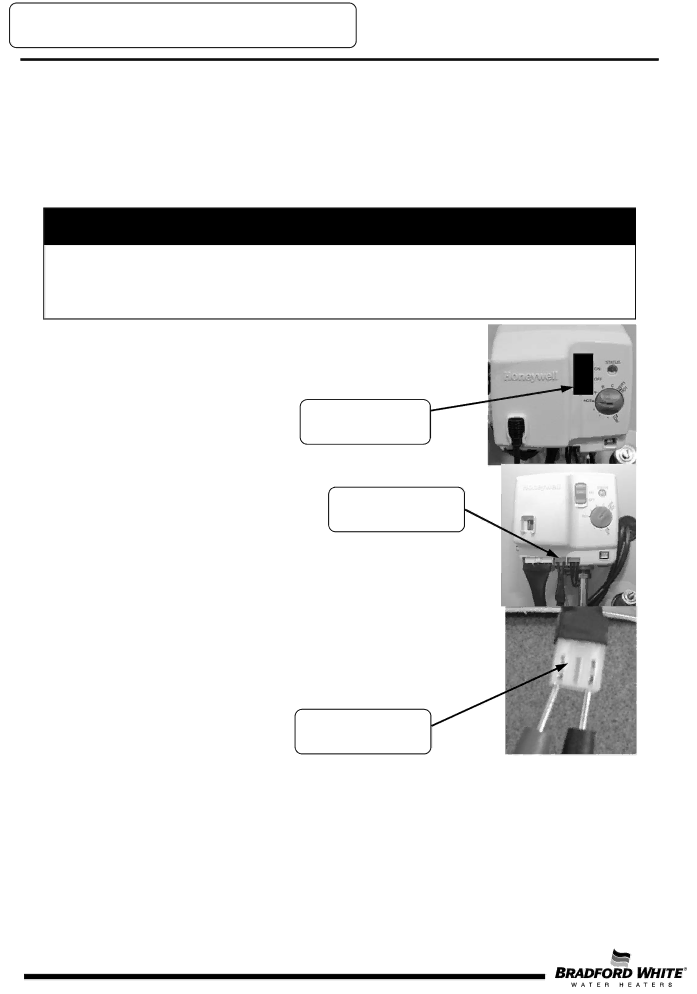

Gas control power

switch

Step 2. Disconnect the flammable vapor sensor harness

from the gas control.Flammable vapor

sensor harness

Step 3. Using a multi-meter set to the ohms setting, measure the resistance of the flammable vapor sensor and resettable ther- mal switch. The resistance must be between 3,000 and 48,000 ohms. If the resistance is out of this range, verify that the re- settable thermal switch has not been tripped. If it hasn’t,

the thermal switch.

Flammable vapor

sensor harness

115 VAC Circuit Trace

Move the gas control power switch to the “OFF”

Step 1. position.

electronic probes or small diameter wire pins inserted into connector.

Do not use standard multi-meter probes for this testing.

Flammable Vapor Sensor Testing

Gas Control Assembly to the Thermal Well (cont’d)

Step 8. To resume operation, follow the instructions located on the water heater lighting instruction label. Or, use the lighting instructions located in the water heater installation and operating manual.

Flammable Vapor Sensor Testing

![]() CAUTION

CAUTION

Doing so will damage the connector. Use special pin type

40