5. CONNECTING TO GAS

This appliance is designed to be installed with an |

|

appliance flexible connection only. Supply piping should |

|

not be less than R³/8 (³/8" B.S.P.). Connection is made |

|

to the Rc½ (½" B.S.P.) female threaded entry pipe |

|

located just below the hotplate level on the rear left hand |

|

side of the appliance. |

|

Carry out a gas tightness test after connecting to the |

|

gas supply. |

|

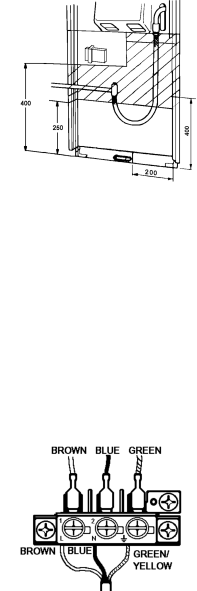

The gas bayonet connector must be fitted in the shaded |

|

area indicated in Fig. 3. Take into account that it must |

|

be possible to pull the appliance forward sufficiently. |

|

The hose must not get caught on the stability bracket. | Fig.3 |

| All dimensions in mm |

IMPORTANT: FLEXIBLE TUBING USED MUST

COMPLY WITH BS. 669 CURRENT EDITION. L.P.G. FLEXIBLE CONNECTIONS MUST BE OF A TYPE SUITABLE FOR L.P.G. AND CAPABLE OF OPERATION UP TO 50MBAR AND TO CARRY A RED STRIPE, BAND OR LABEL.

NOTE: ONLY LIQUID SEALANTS CAN BE USED IN THREADED GAS CONNECTIONS. DO NOT USE P.T.F.E. TAPE.

6. CONNECTION TO THE ELECTRICITY SUPPLY

WARNING: THIS APPLIANCE MUST BE EARTHED. DO NOT EARTH THIS APPLIANCE TO THE GAS SUPPLY PIPING.

This appliance must be connected to

(i)Replaced totally by a longer cable at least 0.75mm2 nominal cross sectional area (24/0.2mm).

(ii)Extended by using a B.E.A.B. approved

IF THE MOULDED PLUG IS CUT FROM THE CABLE FOR ANY REASON, IT MUST BE DESTROYED OR DISPOSED

OF SAFELY, AS THE PROTRUDING |

|

WIRES WILL BE AN ELECTRIC SHOCK | Fig.4 |

HAZARD. | |

If any other type of plug is used it should incorporate a |

|

3 amp fuse in either the plug or at the distribution |

|

board. If the cable has to be threaded through small |

|

apertures in cabinets etc., it may be disconnected from |

|

the appliance, then |

|

DO NOT EXTEND THE CABLE USING PLASTIC OR

CERAMIC CONNECTION TERMINAL BLOCKS AND/OR INSULATION TAPE.

ALL EXTERNAL WIRING BETWEEN THE APPLIANCE AND THE ELECTRICAL SUPPLY SHALL COMPLY WITH I.E.E. WIRING REGULATIONS.

If the wiring is extended or a completely new cable fitted a

45