Fuse Protection

The 24VAC circuitry is protected with a 3 amp fuse on the Flame Control Boards (FCB) and a 7.5 amp fuse on the Central Control Board. If the fuse opens, a red LED located near the fuse will light. See Figures 17 and 18. If the red LED is illuminated, replace the fuse. Repeated failure of the fuse is an indication of possible damage to the ignition control. The 120VAC circuits of each Flame Control Board is protected with a 10 amp (15 amp for the CCB) fuse located on the Power Distribution Board (PDB). The 20 amp pump fuse is also on the PDB.

Recommended Replacement fuses:

Littlefuse automotive fuse p/n 29707.5 for the 7.5 amp

CCB fuse, and Littlefuse p/n 297003 for the 3 amp FCB fuses.

OPERATION

IMPORTANT

Only qualified personnel shall perform the initial firing of the heater. If you have questions, please contact the factory or your local A.O. Smith representative.

Operation and troubleshooting instructions are included with this manual. By using these instructions, the user may be able to make minor operational adjustments. The user should not attempt repairs, but should contact a service technician or gas supplier for service.

GENERAL

Never operate the boiler without first making sure the boiler and system are filled with water, in addition:

For hot water supply Boiler installations:

•Make sure a temperature and pressure relief valve is installed on the storage tank if used. Also check for leaks.

For heating boiler installations:

•Make sure that the boiler and system have been purged of air and checked for leaks.

FILLING AND PURGING WATER SYSTEM

(A.) Hydronic Heating Installation:

1.Fill system through bypass until pressure approaches desired system pressure. Close bypass valve and permit pressure to be established by the pressure reducing valve.

2.Vent all high points in system to purge system of air.

Provisions should be made to permit manual venting of radiators or convectors.

(B.) Hot Water Supply Installation:

1.Close the systems drain valve.

2.Open a nearby hot water faucet to permit the air in the system to escape.

3.Fully open the cold water inlet pipe valve allowing the heater and piping to be filled.

4.Close the hot water faucet as water starts to flow.

5.The heater is ready to be operated.

PURGING OF GAS LINE

Gas line purging is required with new piping or systems in which air has entered.

![]() CAUTION

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS EXPERIENCED IN THIS TYPE OF GAS SERVICE TO AVOID RISK OF FIRE OR EXPLOSION. PURGE DISCHARGE MUST NOT ENTER CONFINED AREAS OR SPACES WHERE IGNITION CAN OCCUR. THE AREA MUST BE WELL VENTILATED AND ALL SOURCES OF IGNITION MUST BE DEACTIVATED OR REMOVED.

BEFORE PLACING THE BOILER IN OPERATION, CHECK FOR GAS LEAKAGE. USE A SOAP AND WATER SOLUTION OR OTHER MATERIALACCEPTABLE FOR THE PURPOSE OF LOCATING GAS LEAKS. DO NOT USE MATCHES, CANDLES, FLAME OR OTHER SOURCES OF IGNITION FOR THIS PURPOSE.

![]() WARNING

WARNING

THE GAS VALVE MUST HAVE BEEN IN THE OFF POSITION FOR AT LEAST 5 MINUTES. This waiting period is an important safety step. Its purpose is to permit gas that may have accumulated in the combustion chamber to clear. IF YOU DETECT GAS ODOR AT THE END OF THIS PERIOD DO NOT PROCEED WITH LIGHTING. RECOGNIZE THAT GAS EVEN IF IT SEEMS WEAK, MAY INDICATE PRESENCE OF ACCUMULATED GAS SOMEPLACE IN THE AREA WITH RISK OF FIRE OR EXPLOSION. SEE THE FRONT PAGE FOR STEPS TO BE TAKEN.

INLET GAS PRESSURE

The inlet gas pressure is measured by removing the low gas pressure switch located on the main gas manifold which is upstream of the unit's combination gas valves. See Figure 14. The maximum value specified in the table must not be exceeded. The minimum values, shown in Table 19, must be maintained under both load and no load conditions (static and firing conditions). The combination gas valves supplied with the boiler are for low pressure service. If upstream pressure exceeds 14.0" W.C., an intermediate gas pressure regulator of the lockup type must be installed.

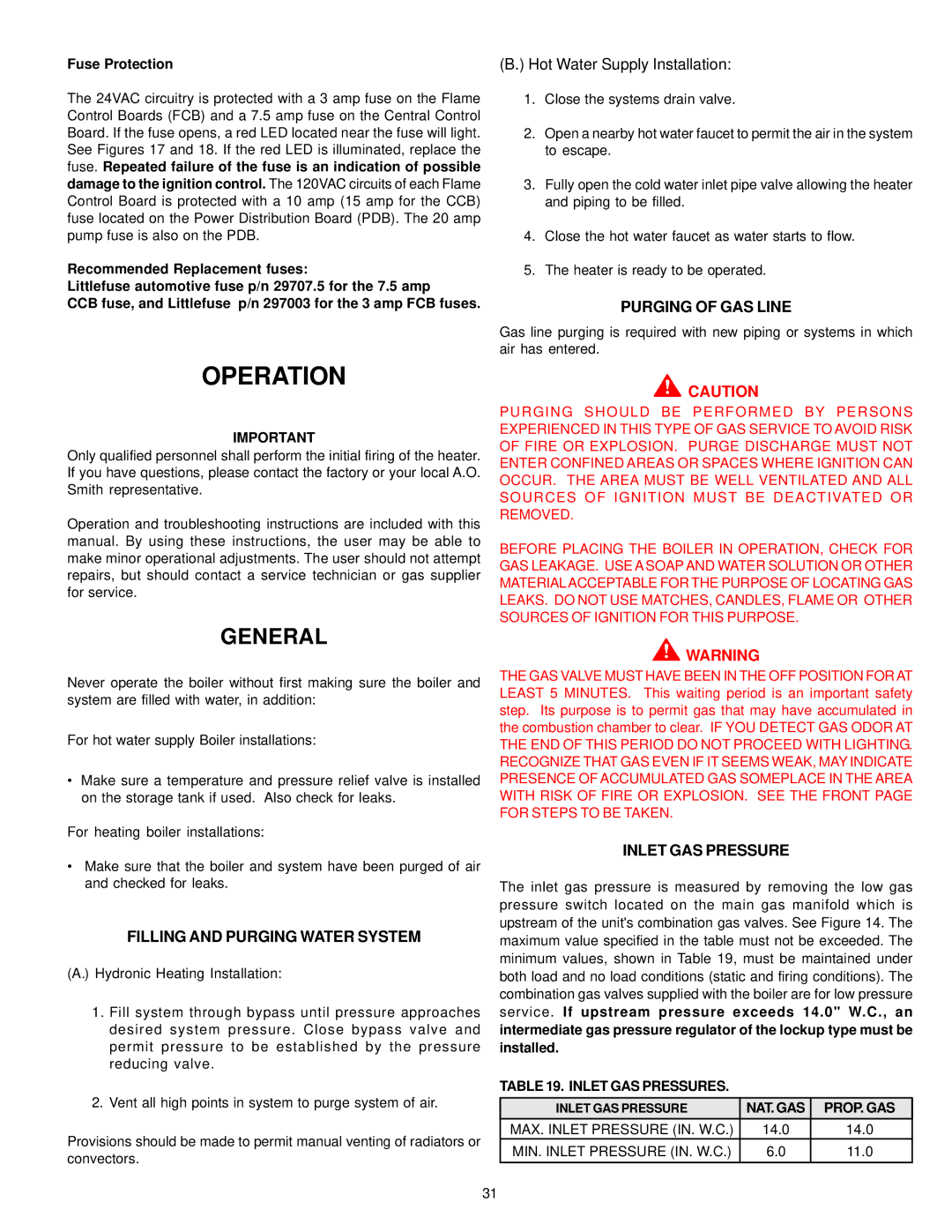

TABLE 19. INLET GAS PRESSURES.

INLET GAS PRESSURE | NAT. GAS | PROP. GAS |

MAX. INLET PRESSURE (IN. W.C.) | 14.0 | 14.0 |

MIN. INLET PRESSURE (IN. W.C.) | 6.0 | 11.0 |

31