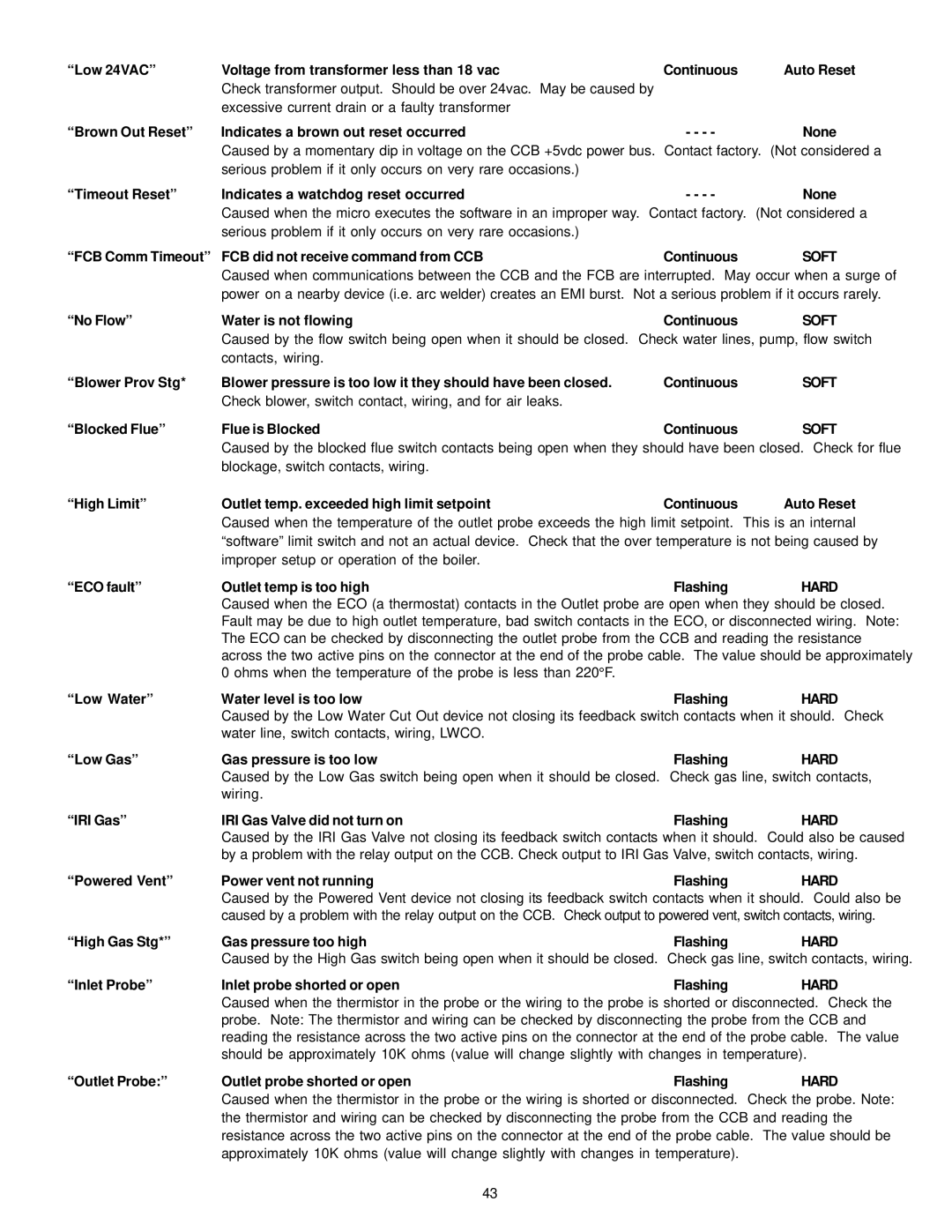

“Low 24VAC” | Voltage from transformer less than 18 vac | Continuous | Auto Reset |

| Check transformer output. Should be over 24vac. May be caused by |

|

|

| excessive current drain or a faulty transformer |

|

|

“Brown Out Reset” | Indicates a brown out reset occurred | - - - - | None |

| Caused by a momentary dip in voltage on the CCB +5vdc power bus. Contact factory. (Not considered a | ||

| serious problem if it only occurs on very rare occasions.) |

|

|

“Timeout Reset” | Indicates a watchdog reset occurred | - - - - | None |

| Caused when the micro executes the software in an improper way. Contact factory. (Not considered a | ||

| serious problem if it only occurs on very rare occasions.) |

|

|

“FCB Comm Timeout” | FCB did not receive command from CCB | Continuous | SOFT |

| Caused when communications between the CCB and the FCB are interrupted. May occur when a surge of | ||

| power on a nearby device (i.e. arc welder) creates an EMI burst. Not a serious problem if it occurs rarely. | ||

“No Flow” | Water is not flowing | Continuous | SOFT |

| Caused by the flow switch being open when it should be closed. Check water lines, pump, flow switch | ||

| contacts, wiring. |

|

|

“Blower Prov Stg* | Blower pressure is too low it they should have been closed. | Continuous | SOFT |

| Check blower, switch contact, wiring, and for air leaks. |

|

|

“Blocked Flue” | Flue is Blocked | Continuous | SOFT |

| Caused by the blocked flue switch contacts being open when they should have been closed. Check for flue | ||

| blockage, switch contacts, wiring. |

|

|

“High Limit” | Outlet temp. exceeded high limit setpoint | Continuous | Auto Reset |

| Caused when the temperature of the outlet probe exceeds the high limit setpoint. This is an internal | ||

| “software” limit switch and not an actual device. Check that the over temperature is not being caused by | ||

| improper setup or operation of the boiler. |

|

|

“ECO fault” | Outlet temp is too high | Flashing | HARD |

| Caused when the ECO (a thermostat) contacts in the Outlet probe are open when they should be closed. | ||

| Fault may be due to high outlet temperature, bad switch contacts in the ECO, or disconnected wiring. Note: | ||

| The ECO can be checked by disconnecting the outlet probe from the CCB and reading the resistance | ||

| across the two active pins on the connector at the end of the probe cable. The value should be approximately | ||

| 0 ohms when the temperature of the probe is less than 220°F. |

|

|

“Low Water” | Water level is too low | Flashing | HARD |

| Caused by the Low Water Cut Out device not closing its feedback switch contacts when it should. Check | ||

| water line, switch contacts, wiring, LWCO. |

|

|

“Low Gas” | Gas pressure is too low | Flashing | HARD |

| Caused by the Low Gas switch being open when it should be closed. Check gas line, switch contacts, | ||

| wiring. |

|

|

“IRI Gas” | IRI Gas Valve did not turn on | Flashing | HARD |

| Caused by the IRI Gas Valve not closing its feedback switch contacts when it should. Could also be caused | ||

| by a problem with the relay output on the CCB. Check output to IRI Gas Valve, switch contacts, wiring. | ||

“Powered Vent” | Power vent not running | Flashing | HARD |

| Caused by the Powered Vent device not closing its feedback switch contacts when it should. Could also be | ||

| caused by a problem with the relay output on the CCB. Check output to powered vent, switch contacts, wiring. | ||

“High Gas Stg*” | Gas pressure too high | Flashing | HARD |

| Caused by the High Gas switch being open when it should be closed. Check gas line, switch contacts, wiring. | ||

“Inlet Probe” | Inlet probe shorted or open | Flashing | HARD |

| Caused when the thermistor in the probe or the wiring to the probe is shorted or disconnected. Check the | ||

| probe. Note: The thermistor and wiring can be checked by disconnecting the probe from the CCB and | ||

| reading the resistance across the two active pins on the connector at the end of the probe cable. The value | ||

| should be approximately 10K ohms (value will change slightly with changes in temperature). | ||

“Outlet Probe:” | Outlet probe shorted or open | Flashing | HARD |

Caused when the thermistor in the probe or the wiring is shorted or disconnected. Check the probe. Note: the thermistor and wiring can be checked by disconnecting the probe from the CCB and reading the resistance across the two active pins on the connector at the end of the probe cable. The value should be approximately 10K ohms (value will change slightly with changes in temperature).

43