SYSTEM INSTALLATIONS

1. CONVENTIONAL INSTALLATIONS

All modern hydronic type boilers are exceptionally fast heating units. The low water volumes in relation to firing rates require special attention to water flow rates for smooth, efficient operation. These considerations for the A. O. Smith copper heat exchanger boilers are covered below.

Conventional 200F (100C) drop in systems for a fully loaded boiler will maintain the following approximate flow rates:

MODELS | GPM (LPM) |

|

|

23 (87) | |

30 (114) | |

35 (132) | |

39 (148) | |

46 (175) |

Figure 7 on page 14 shows a typical installation of the boiler with pipe sizing and circulator selected by the installer to provide adequate water flow whenever the boiler is firing.

In a system with several large zones of which any might be smaller than approximately 1/3 of the system should include a hydronic balancer as shown in Figure 7. The balancer connects between the system supply and the return line before the circulator inlet. Adjustment of the balancing cock should permit adequate boiler flow rate when only the smallest zone is in operation.

Attention should be given to balancing inputs and water flow rates where wide variations of system flow rates can occur.

The recommended minimum flow rates that will result in approximately

500F (300C) temperature rise across the boiler are as follows:

MODELS | GPM (LPM) |

|

|

9 (34) | |

12 (45) | |

14 (53) | |

16 (61) | |

18 (69) | |

20 (76) |

If system flow rate is unknown, or if zoning creates extreme variations in flow rates, the boiler should be installed as shown in Figure 11 on this page for A. O. Smith

2.LINEAR-TEMP INSTALLATIONS

A.New Installations

A. O. Smith

a.Unknown system flow rate

b.Varying flow rate as with zoned systems

c.Multiple boiler installations

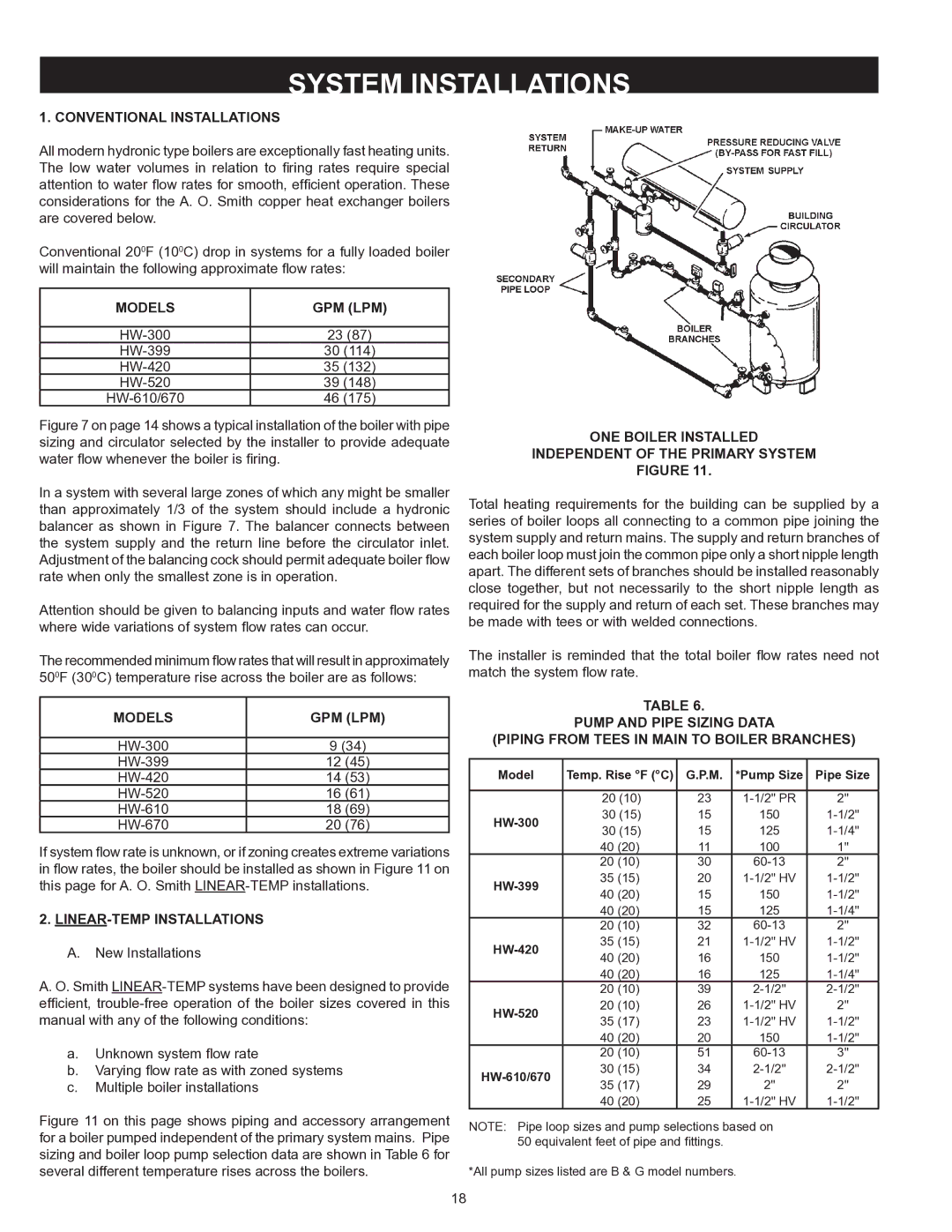

Figure 11 on this page shows piping and accessory arrangement for a boiler pumped independent of the primary system mains. Pipe sizing and boiler loop pump selection data are shown in Table 6 for several different temperature rises across the boilers.

ONE BOILER INSTALLED

INDEPENDENT OF THE PRIMARY SYSTEM

FIGURE 11.

Total heating requirements for the building can be supplied by a series of boiler loops all connecting to a common pipe joining the system supply and return mains. The supply and return branches of each boiler loop must join the common pipe only a short nipple length apart. The different sets of branches should be installed reasonably close together, but not necessarily to the short nipple length as required for the supply and return of each set. These branches may be made with tees or with welded connections.

The installer is reminded that the total boiler flow rates need not match the system flow rate.

TABLE 6.

PUMP AND PIPE SIZING DATA

(PIPING FROM TEES IN MAIN TO BOILER BRANCHES)

Model | Temp. Rise °F (°C) | G.P.M. | *Pump Size | Pipe Size | |

|

|

|

|

| |

| 20 (10) | 23 | 2" | ||

30 (15) | 15 | 150 | |||

30 (15) | 15 | 125 | |||

| |||||

| 40 (20) | 11 | 100 | 1" | |

| 20 (10) | 30 | 2" | ||

35 (15) | 20 | ||||

40 (20) | 15 | 150 | |||

| |||||

| 40 (20) | 15 | 125 | ||

| 20 (10) | 32 | 2" | ||

35 (15) | 21 | ||||

40 (20) | 16 | 150 | |||

| |||||

| 40 (20) | 16 | 125 | ||

| 20 (10) | 39 | |||

20 (10) | 26 | 2" | |||

35 (17) | 23 | ||||

| |||||

| 40 (20) | 20 | 150 | ||

| 20 (10) | 51 | 3" | ||

| 30 (15) | 34 | |||

35 (17) | 29 | 2" | 2" | ||

| |||||

| 40 (20) | 25 |

NOTE: Pipe loop sizes and pump selections based on

50 equivalent feet of pipe and fittings.

*All pump sizes listed are B & G model numbers.

18