THERMAL BALANCER

Figure 4 shows the internal wiring of the thermal balancer. The device may be tested after disconnecting the four leads from their respective terminals on the unit.

1.Apply a test light to the yellow and red leads.

•The lamp should light as the contact in this circuit is normally closed when the resistor is cool.

2.Apply a light to the black and yellow leads.

•The lamp should not light as the contact in this circuit is normally open when the resistor is cool.

3.Remove the test light.

4.Apply 120 volts to the white and red leads which power the 1900 ohm resistor. After a warming period the contacts of the thermal balancer should operate.

5.Remove the test light.

6.Apply the test light as described in steps 1 and 2.

While the resistor is still warm the lamp indications should be the opposite as described previously.

FIGURE 4.

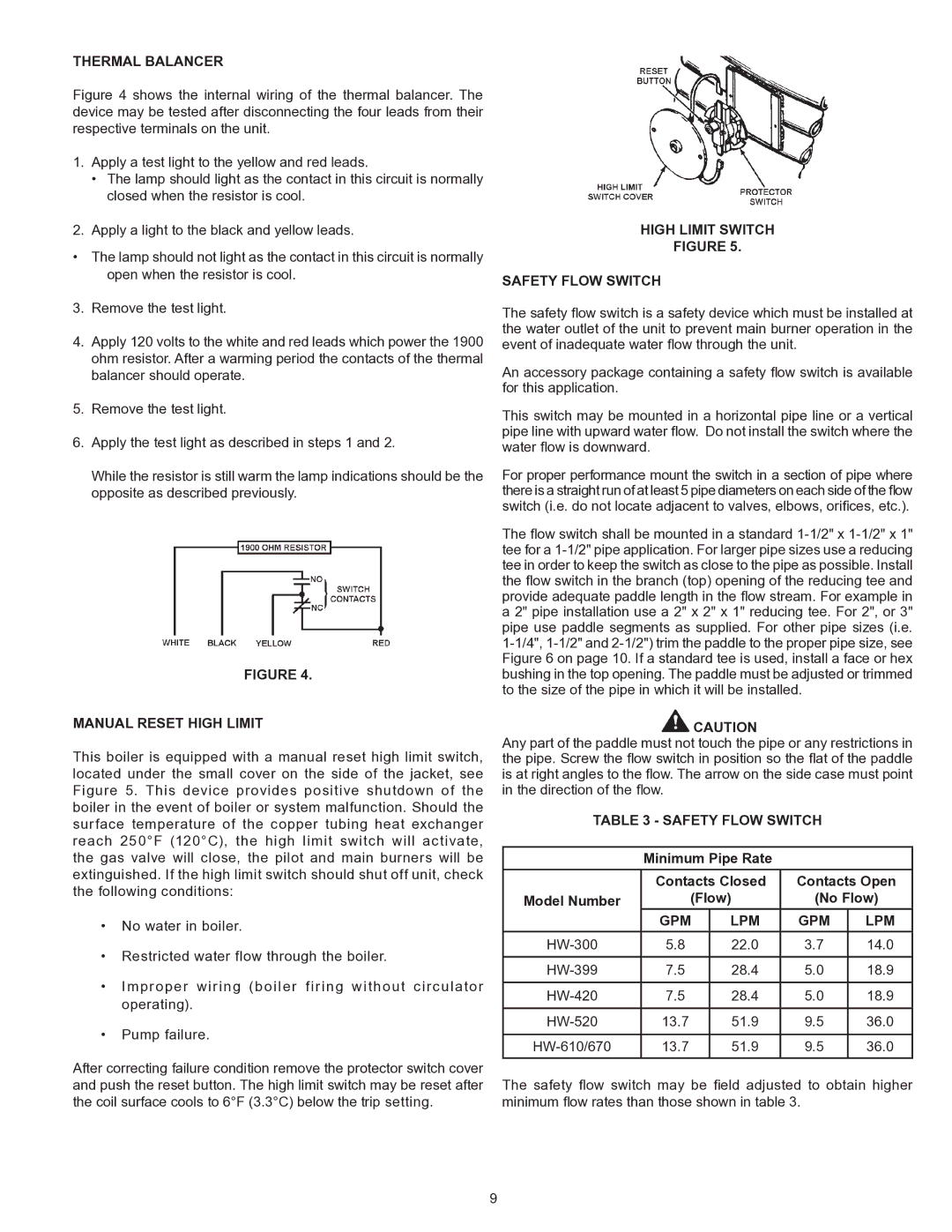

MANUAL RESET HIGH LIMIT

This boiler is equipped with a manual reset high limit switch, located under the small cover on the side of the jacket, see Figure 5. This device provides positive shutdown of the boiler in the event of boiler or system malfunction. Should the surface temperature of the copper tubing heat exchanger reach 250°F (120°C), the high limit switch will activate, the gas valve will close, the pilot and main burners will be extinguished. If the high limit switch should shut off unit, check the following conditions:

•No water in boiler.

•Restricted water flow through the boiler.

•Improper wiring (boiler firing without circulator operating).

•Pump failure.

After correcting failure condition remove the protector switch cover and push the reset button. The high limit switch may be reset after the coil surface cools to 6°F (3.3°C) below the trip setting.

HIGH LIMIT SWITCH

FIGURE 5.

SAFETY FLOW SWITCH

The safety flow switch is a safety device which must be installed at the water outlet of the unit to prevent main burner operation in the event of inadequate water flow through the unit.

An accessory package containing a safety flow switch is available for this application.

This switch may be mounted in a horizontal pipe line or a vertical pipe line with upward water flow. Do not install the switch where the water flow is downward.

For proper performance mount the switch in a section of pipe where there is a straight run of at least 5 pipe diameters on each side of the flow switch (i.e. do not locate adjacent to valves, elbows, orifices, etc.).

The flow switch shall be mounted in a standard

![]() CAUTION

CAUTION

Any part of the paddle must not touch the pipe or any restrictions in the pipe. Screw the flow switch in position so the flat of the paddle is at right angles to the flow. The arrow on the side case must point in the direction of the flow.

TABLE 3 - SAFETY FLOW SWITCH

Minimum Pipe Rate

| Contacts Closed | Contacts Open | ||

Model Number | (Flow) | (No Flow) | ||

| GPM | LPM | GPM | LPM |

5.8 | 22.0 | 3.7 | 14.0 | |

7.5 | 28.4 | 5.0 | 18.9 | |

|

|

|

|

|

7.5 | 28.4 | 5.0 | 18.9 | |

|

|

|

|

|

13.7 | 51.9 | 9.5 | 36.0 | |

|

|

|

|

|

13.7 | 51.9 | 9.5 | 36.0 | |

The safety flow switch may be field adjusted to obtain higher minimum flow rates than those shown in table 3.

9