Tennessee Waltz Parkway Ashland City, TN

Models HW 300, 399, 420, 520, 610

Important Definitions

Safe INSTALLATION, USE and Service

General Safety

Table of Contents

Propane Natural

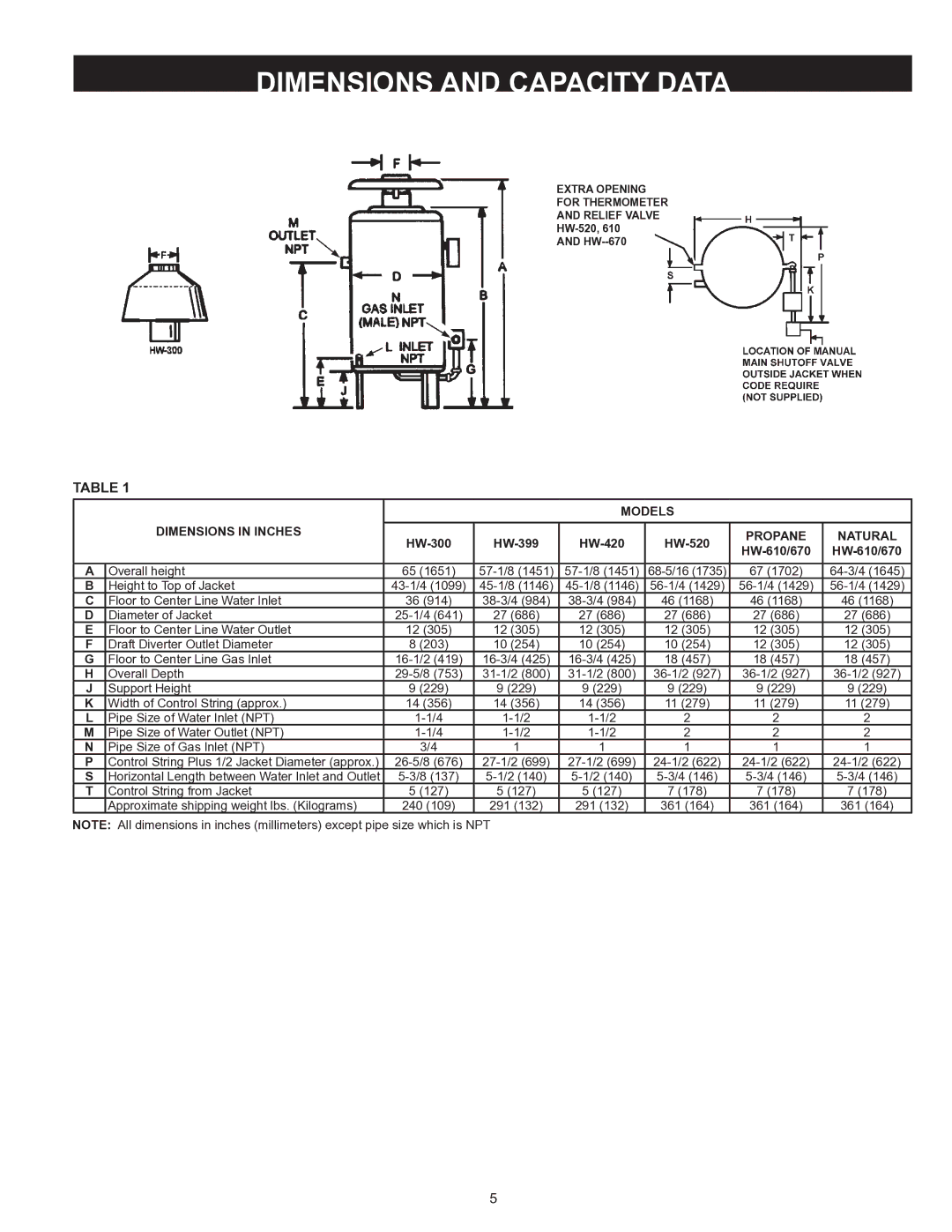

Dimensions and Capacity Data

27.7 33.3

Recovery Capacities

LIQUefied petroleum gas models

High Altitude Installations

Introduction

Controls and Function

High Limit Switch Safety Flow Switch

Manual Reset High Limit

Thermal Balancer

GPM LPM

Safety Relief Valves

Tank Temperature Control

Thermometers

General

Drain Valve Not Supplied

Required Ability

Canadian Installations

Confined Space S. Installations

AIR Requirements

Unconfined Space

Typical Boiler Installation

Installation Clearances

Venting

Leveling

Connecting Boiler to a Common Vent

Vent Pipe Installation

Draft Hood

Vent Connection

Venting System

Venting Sidewall Optional Power Vent System

Multiple Vent Table

Model HW-300 Boiler

Combined Vent Sizing Tables

Conventional Installations

System Installations

LINEAR-TEMP Installations

ONE Boiler Installed Independent of the Primary System

Schematic of the LINEAR-TEMPSYSTEM

NO. Suggested Items for Installation

Boiler Inlet Outlet Sizes

Minimum Branch Sizes to Boilers

GAS Connections

Correct GAS

Purging and Sizing

Specific Multiplier Gravity

Example

GAS Pressure Regulators

Model Rated Manifold Pressure Number Input Natural Propane

Wiring Connections

Wiring

D. System

HW 300 to

Single Stage I.I.D. Honeywell GAS Valve

HW 300 thru 670. Natural and Propane GAS U.S. & Canada

LINEAR-TEMP Installations

Boilers and Secondary Circulator are Controlled by

Page

MODELS, Jucntion BOX W/4 Terminals

Canadian MODELS, Junction BOX W/6 Terminals

Canadian MODELS, Junction BOX W/6 Terminals

Schematic

MODELS, Junction BOX W/4 Terminals

MODELS, Junction BOX W/4 Terminals

Piping

Wiring Figures 16 and 17 on Pages 24

Commercial Boiler with Vertical Tank

USE this Table for Correct Pump and Water Pipe Size

Commercial Boiler with Horizontal Tank

Commercial Boiler with Vertical TANK, CER-TEMP

Wiring Figures 21 to 27 on Pages 28 to

HW-300 HW-399 HW-420 HW-520

Three HW-520s, HW-610s or HW-670s UP-FLOW Model

USE this Table for Correct Pump and Water Pipe Size

Filling the System

Operation and START-UP Instructions

Pilot and Main Burner

Main Burner

Pilot Burner Electronic Ignition

Refer to Operating at Full Input or Full Capacity

Checking and Adjusting the Input

Consumption Rate

Stage Main Burner Operation Flame Current Sensed

For Your Safety Read Before Lighting

URN Pilo T Firing VA LVE Counterclockwise

SET T HE Thermostat to Lowwest Setting

Relief Valve

General Maintenance

Manual Reset High Limit Switch Continuity Test

PRE-TROUBLESHOOTING

Cleaning and Flushing Instructions

HOT Water Supply Boilers Preventive Maintenance

Internal Contaminants

CER-TEMP 80 Recovery System Checkout Procedure

Troubleshooting

YES

Is ceramic insulator surrounding the electrode in good

Burner ignition problems?

Condition not cracked or broken?

Is there excessive draft conditions that may cause pilot

MV & MV/PV?

Replace pilot burner assembly

Location of LEDs Flame LED Yellow

LED Status and Troubleshooting

Status LED Green

OFF

No Call for Heat Not applicable None

OFF

Conditions and Exceptions

Limited Warranty