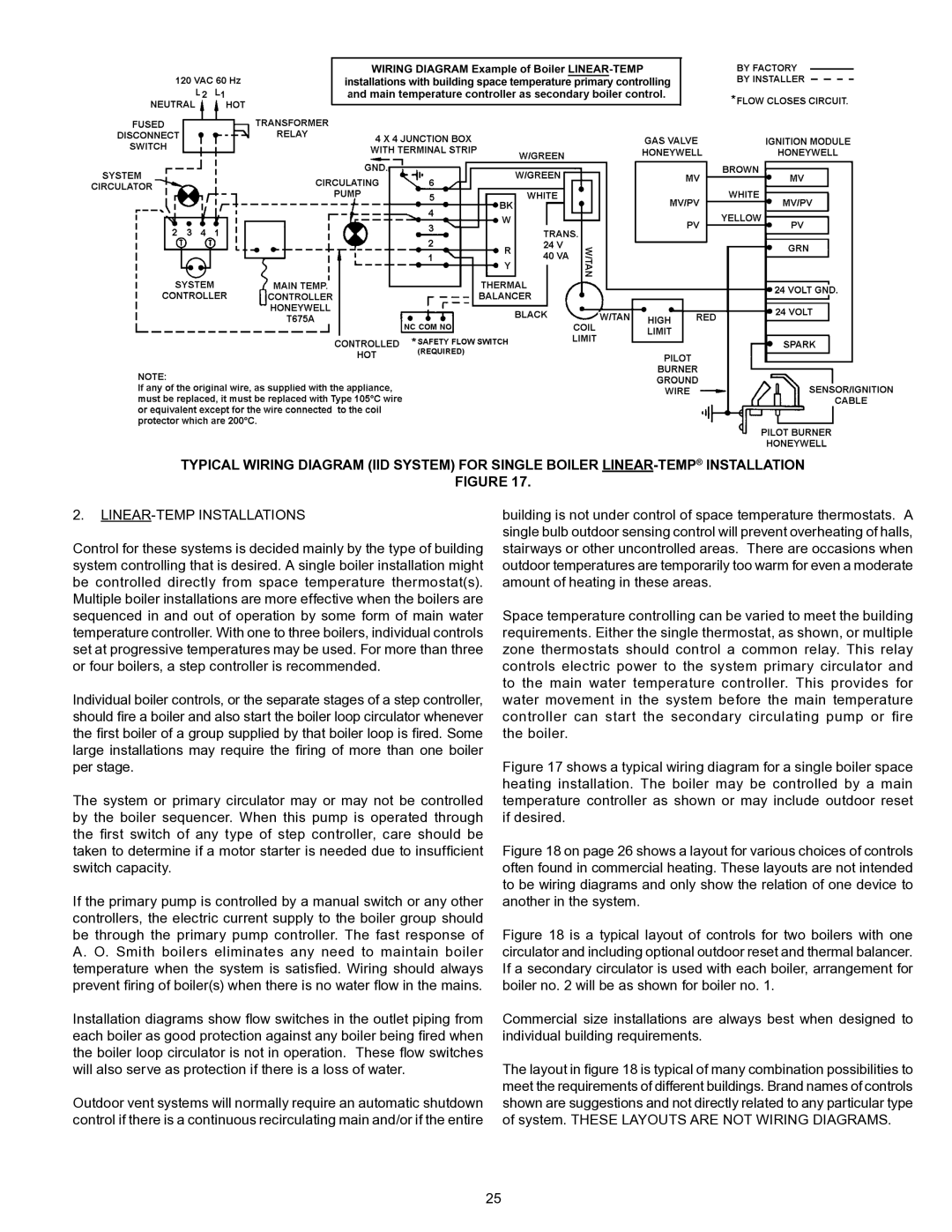

TYPICAL WIRING DIAGRAM (IID SYSTEM) FOR SINGLE BOILER

FIGURE 17.

2.LINEAR-TEMP INSTALLATIONS

Control for these systems is decided mainly by the type of building system controlling that is desired. A single boiler installation might be controlled directly from space temperature thermostat(s). Multiple boiler installations are more effective when the boilers are sequenced in and out of operation by some form of main water temperature controller. With one to three boilers, individual controls set at progressive temperatures may be used. For more than three or four boilers, a step controller is recommended.

Individual boiler controls, or the separate stages of a step controller, should fire a boiler and also start the boiler loop circulator whenever the first boiler of a group supplied by that boiler loop is fired. Some large installations may require the firing of more than one boiler per stage.

The system or primary circulator may or may not be controlled by the boiler sequencer. When this pump is operated through the first switch of any type of step controller, care should be taken to determine if a motor starter is needed due to insufficient switch capacity.

If the primary pump is controlled by a manual switch or any other controllers, the electric current supply to the boiler group should be through the primary pump controller. The fast response of A. O. Smith boilers eliminates any need to maintain boiler temperature when the system is satisfied. Wiring should always prevent firing of boiler(s) when there is no water flow in the mains.

Installation diagrams show flow switches in the outlet piping from each boiler as good protection against any boiler being fired when the boiler loop circulator is not in operation. These flow switches will also serve as protection if there is a loss of water.

Outdoor vent systems will normally require an automatic shutdown control if there is a continuous recirculating main and/or if the entire

building is not under control of space temperature thermostats. A single bulb outdoor sensing control will prevent overheating of halls, stairways or other uncontrolled areas. There are occasions when outdoor temperatures are temporarily too warm for even a moderate amount of heating in these areas.

Space temperature controlling can be varied to meet the building requirements. Either the single thermostat, as shown, or multiple zone thermostats should control a common relay. This relay controls electric power to the system primary circulator and to the main water temperature controller. This provides for water movement in the system before the main temperature controller can start the secondary circulating pump or fire the boiler.

Figure 17 shows a typical wiring diagram for a single boiler space heating installation. The boiler may be controlled by a main temperature controller as shown or may include outdoor reset if desired.

Figure 18 on page 26 shows a layout for various choices of controls often found in commercial heating. These layouts are not intended to be wiring diagrams and only show the relation of one device to another in the system.

Figure 18 is a typical layout of controls for two boilers with one circulator and including optional outdoor reset and thermal balancer. If a secondary circulator is used with each boiler, arrangement for boiler no. 2 will be as shown for boiler no. 1.

Commercial size installations are always best when designed to individual building requirements.

The layout in figure 18 is typical of many combination possibilities to meet the requirements of different buildings. Brand names of controls shown are suggestions and not directly related to any particular type of system. THESE LAYOUTS ARE NOT WIRING DIAGRAMS.

25