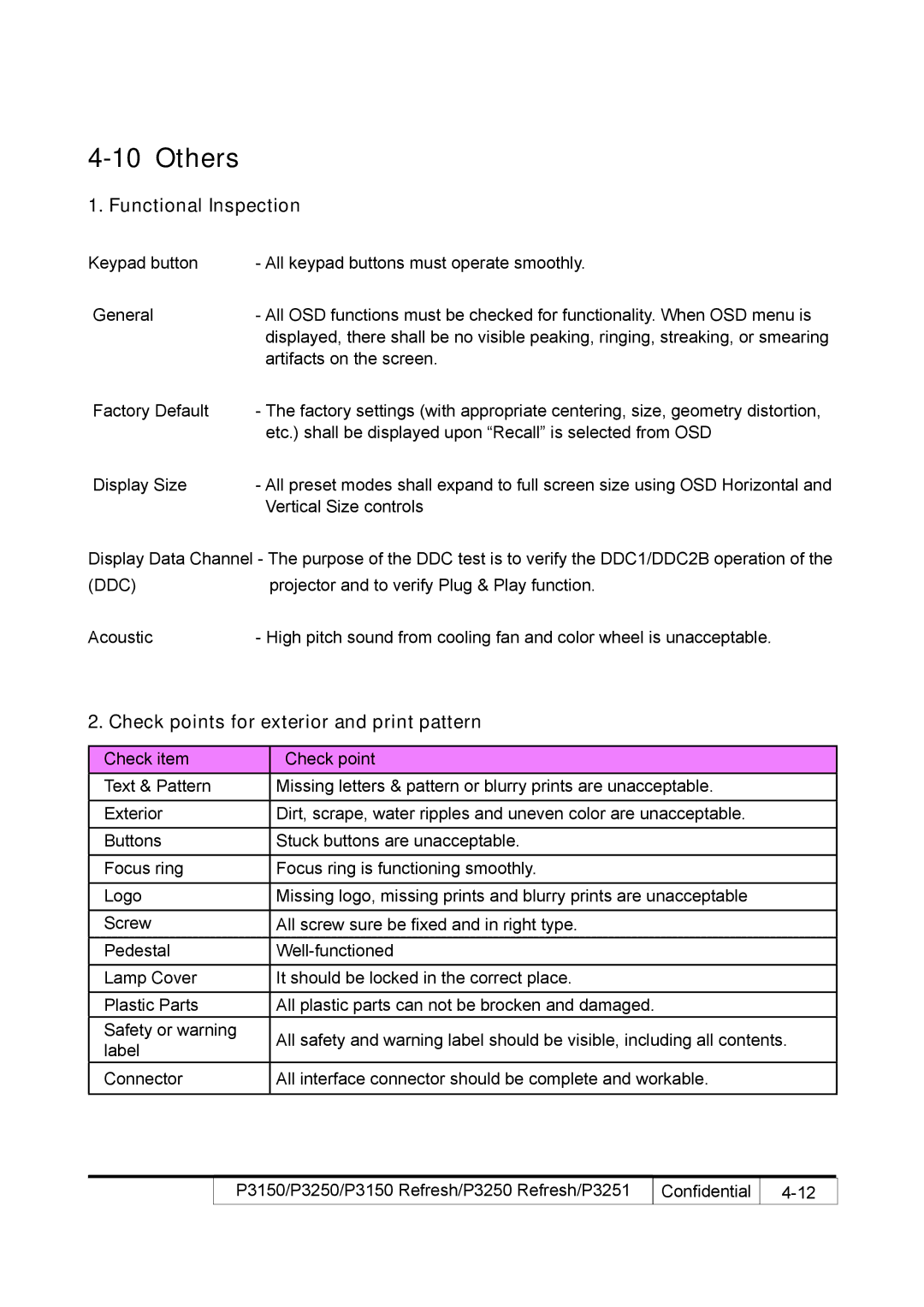

4-10 Others

1. Functional Inspection

Keypad button | - All keypad buttons must operate smoothly. |

General | - All OSD functions must be checked for functionality. When OSD menu is |

| displayed, there shall be no visible peaking, ringing, streaking, or smearing |

| artifacts on the screen. |

Factory Default | - The factory settings (with appropriate centering, size, geometry distortion, |

| etc.) shall be displayed upon “Recall” is selected from OSD |

Display Size | - All preset modes shall expand to full screen size using OSD Horizontal and |

| Vertical Size controls |

Display Data Channel - The purpose of the DDC test is to verify the DDC1/DDC2B operation of the

(DDC) | projector and to verify Plug & Play function. |

Acoustic | - High pitch sound from cooling fan and color wheel is unacceptable. |

2. Check points for exterior and print pattern

Check item | Check point | |

|

| |

Text & Pattern | Missing letters & pattern or blurry prints are unacceptable. | |

|

| |

Exterior | Dirt, scrape, water ripples and uneven color are unacceptable. | |

|

| |

Buttons | Stuck buttons are unacceptable. | |

|

| |

Focus ring | Focus ring is functioning smoothly. | |

|

| |

Logo | Missing logo, missing prints and blurry prints are unacceptable | |

|

| |

Screw | All screw sure be fixed and in right type. | |

Pedestal | ||

|

| |

Lamp Cover | It should be locked in the correct place. | |

|

| |

Plastic Parts | All plastic parts can not be brocken and damaged. | |

Safety or warning | All safety and warning label should be visible, including all contents. | |

label | ||

| ||

Connector | All interface connector should be complete and workable. | |

|

|

P3150/P3250/P3150 Refresh/P3250 Refresh/P3251 | Confidential |

|

|