C. COMPRESSED AIR SYSTEM

The compressed air system of the dryer consists of a number of pneumatic pistons located throughout the dryer, an FRL (Filter/Regulator/Lubricator) assembly, and pneumatic control panel.

1.Air Pistons

The pistons are actuated by solenoid and flow control valves that are under computer control. The pneumatic pistons are used to:

•Tilt the dryer for loading and unloading.

•Open and close load and unload doors

•Operate heat reclaimer.

•Operate the cool down damper and the intake air damper.

2.Filter and Regulator Assembly

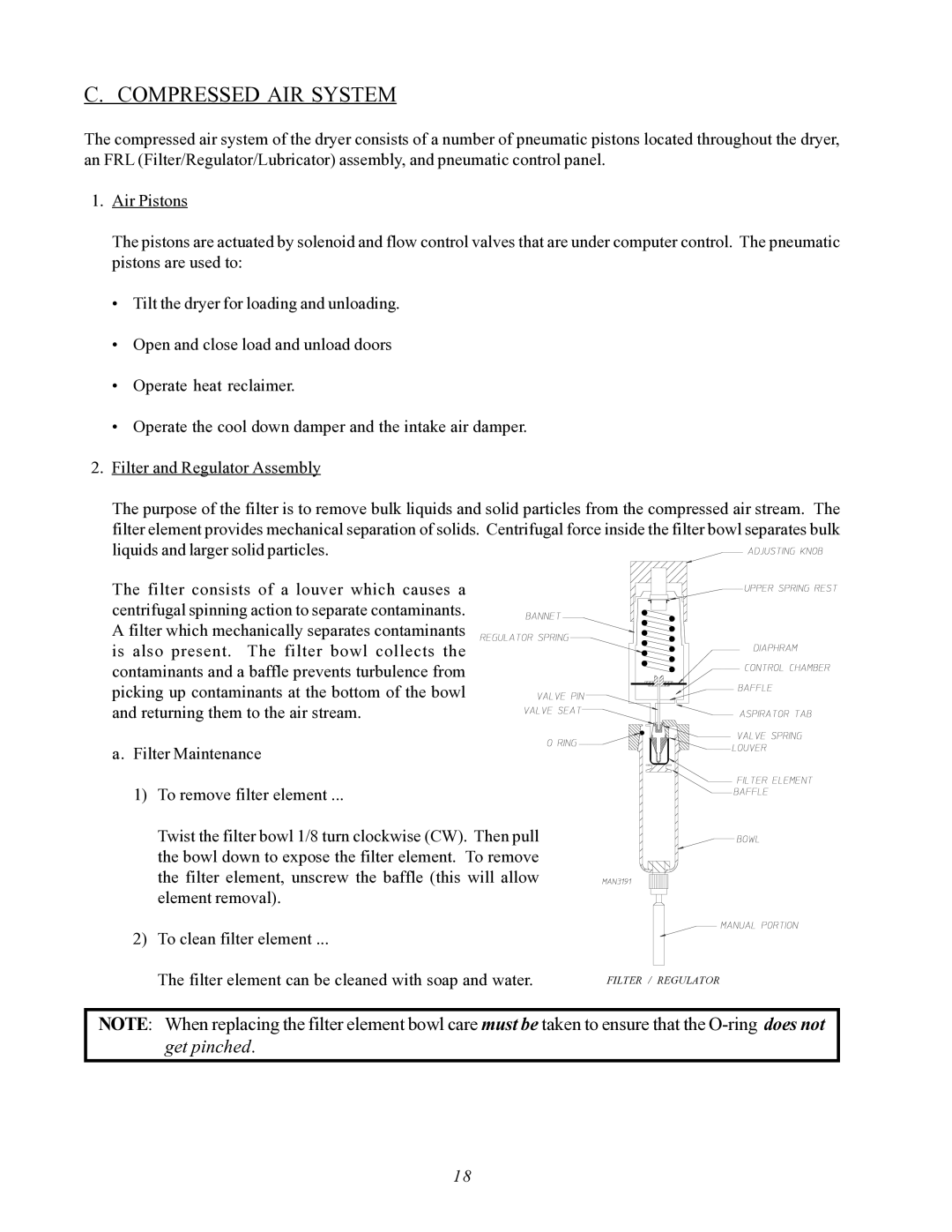

The purpose of the filter is to remove bulk liquids and solid particles from the compressed air stream. The filter element provides mechanical separation of solids. Centrifugal force inside the filter bowl separates bulk liquids and larger solid particles.![]()

The filter consists of a louver which causes a centrifugal spinning action to separate contaminants. A filter which mechanically separates contaminants is also present. The filter bowl collects the contaminants and a baffle prevents turbulence from picking up contaminants at the bottom of the bowl and returning them to the air stream.

a. Filter Maintenance

1) To remove filter element ...

Twist the filter bowl 1/8 turn clockwise (CW). Then pull the bowl down to expose the filter element. To remove the filter element, unscrew the baffle (this will allow element removal).

2) To clean filter element ...

The filter element can be cleaned with soap and water. | FILTER / REGULATOR |

NOTE: When replacing the filter element bowl care must be taken to ensure that the

18