H. ROTATIONAL SENSOR ASSEMBLY

The rotational sensor is a

WARNING: UNDER NO CIRCUMSTANCES SHOULD THE OUTPUT OF THE ROTATIONAL SENSOR BE GROUNDED. DAMAGE WILL RESULT. A

CURRENT LIMITING DEVICE IS REQUIRED.

1.Rotational Sensor

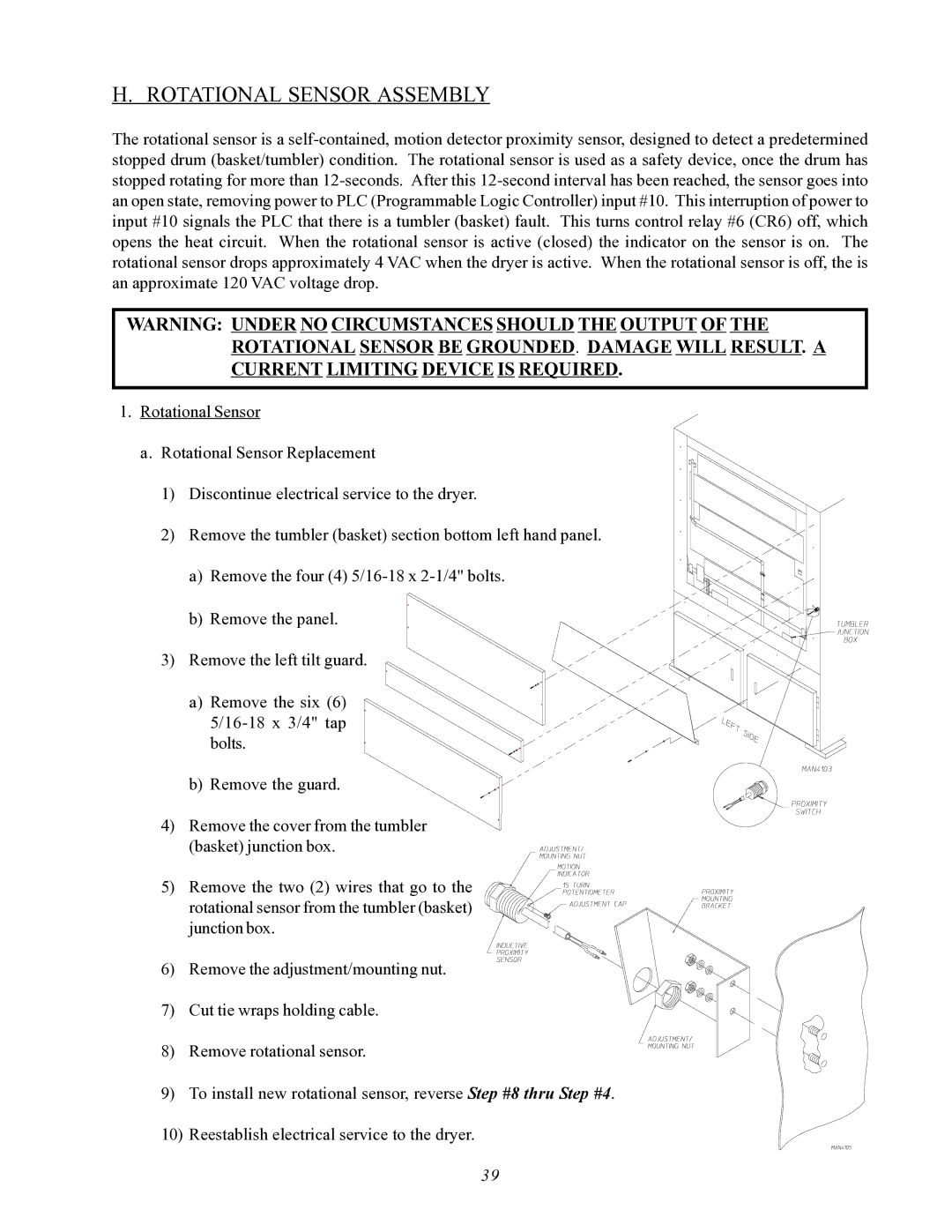

a. Rotational Sensor Replacement

1)Discontinue electrical service to the dryer.

2)Remove the tumbler (basket) section bottom left hand panel. a) Remove the four (4)

b) Remove the panel.

3) Remove the left tilt guard.

a)Remove the six (6)

bolts.

b) Remove the guard.

4)Remove the cover from the tumbler (basket) junction box.

5) Remove the two (2) wires that go to the rotational sensor from the tumbler (basket) junction box.

6) Remove the adjustment/mounting nut.

7) Cut tie wraps holding cable.

8) Remove rotational sensor.

9)To install new rotational sensor, reverse Step #8 thru Step #4.

10)Reestablish electrical service to the dryer.

39