Performance Tests

Performance Test Procedures

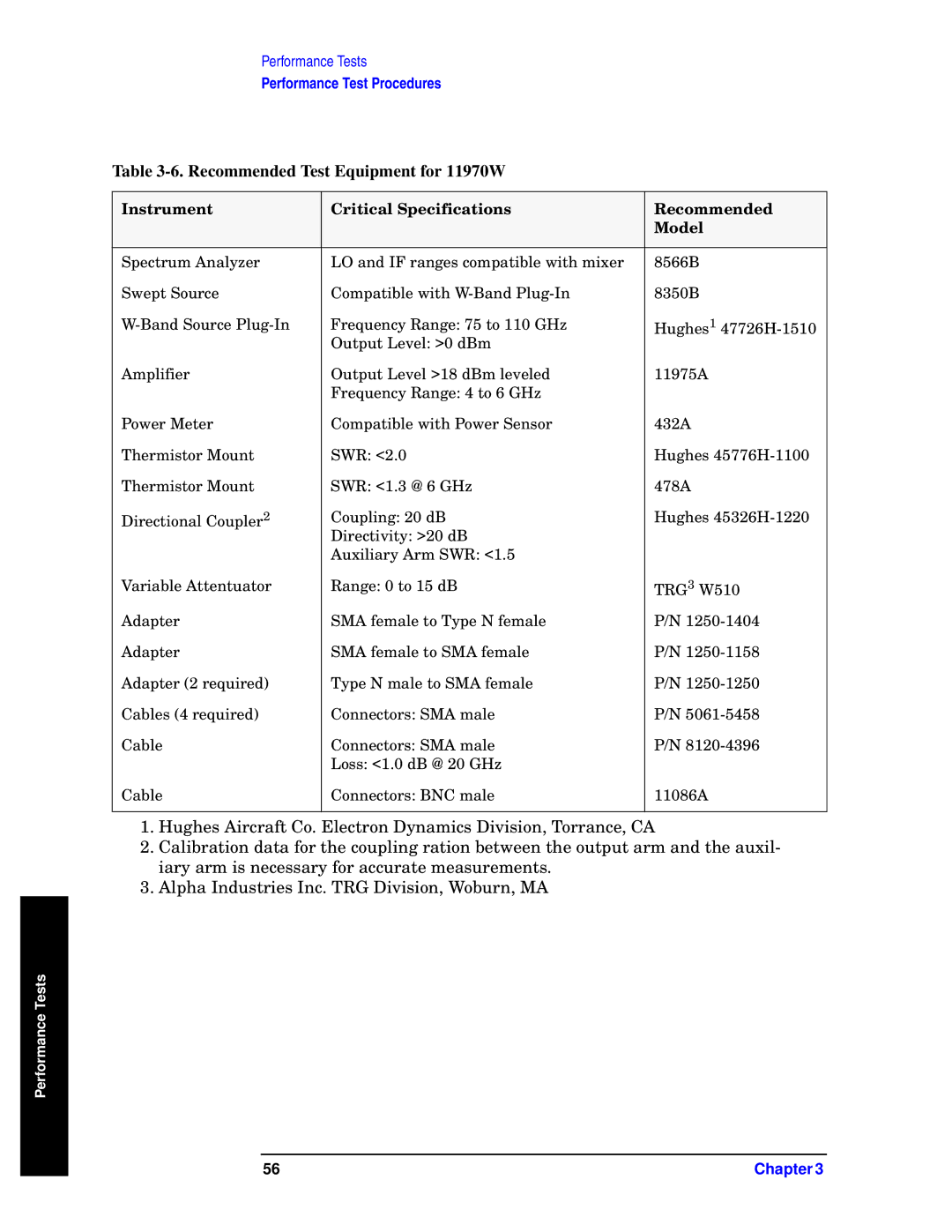

Table 3-6. Recommended Test Equipment for 11970W

Instrument | Critical Specifications | Recommended |

|

| Model |

|

|

|

Spectrum Analyzer | LO and IF ranges compatible with mixer | 8566B |

Swept Source | Compatible with | 8350B |

Frequency Range: 75 to 110 GHz | Hughes1 | |

| Output Level: >0 dBm |

|

Amplifier | Output Level >18 dBm leveled | 11975A |

| Frequency Range: 4 to 6 GHz |

|

Power Meter | Compatible with Power Sensor | 432A |

Thermistor Mount | SWR: <2.0 | Hughes |

Thermistor Mount | SWR: <1.3 @ 6 GHz | 478A |

Directional Coupler2 | Coupling: 20 dB | Hughes |

| Directivity: >20 dB |

|

| Auxiliary Arm SWR: <1.5 |

|

Variable Attentuator | Range: 0 to 15 dB | TRG3 W510 |

Adapter | SMA female to Type N female | P/N |

Adapter | SMA female to SMA female | P/N |

Adapter (2 required) | Type N male to SMA female | P/N |

Cables (4 required) | Connectors: SMA male | P/N |

Cable | Connectors: SMA male | P/N |

| Loss: <1.0 dB @ 20 GHz |

|

Cable | Connectors: BNC male | 11086A |

|

|

|

1.Hughes Aircraft Co. Electron Dynamics Division, Torrance, CA

2.Calibration data for the coupling ration between the output arm and the auxil- iary arm is necessary for accurate measurements.

3.Alpha Industries Inc. TRG Division, Woburn, MA

Performance Tests

56 | Chapter 3 |