Testing the Assembly

You can use the tests and checks in Table

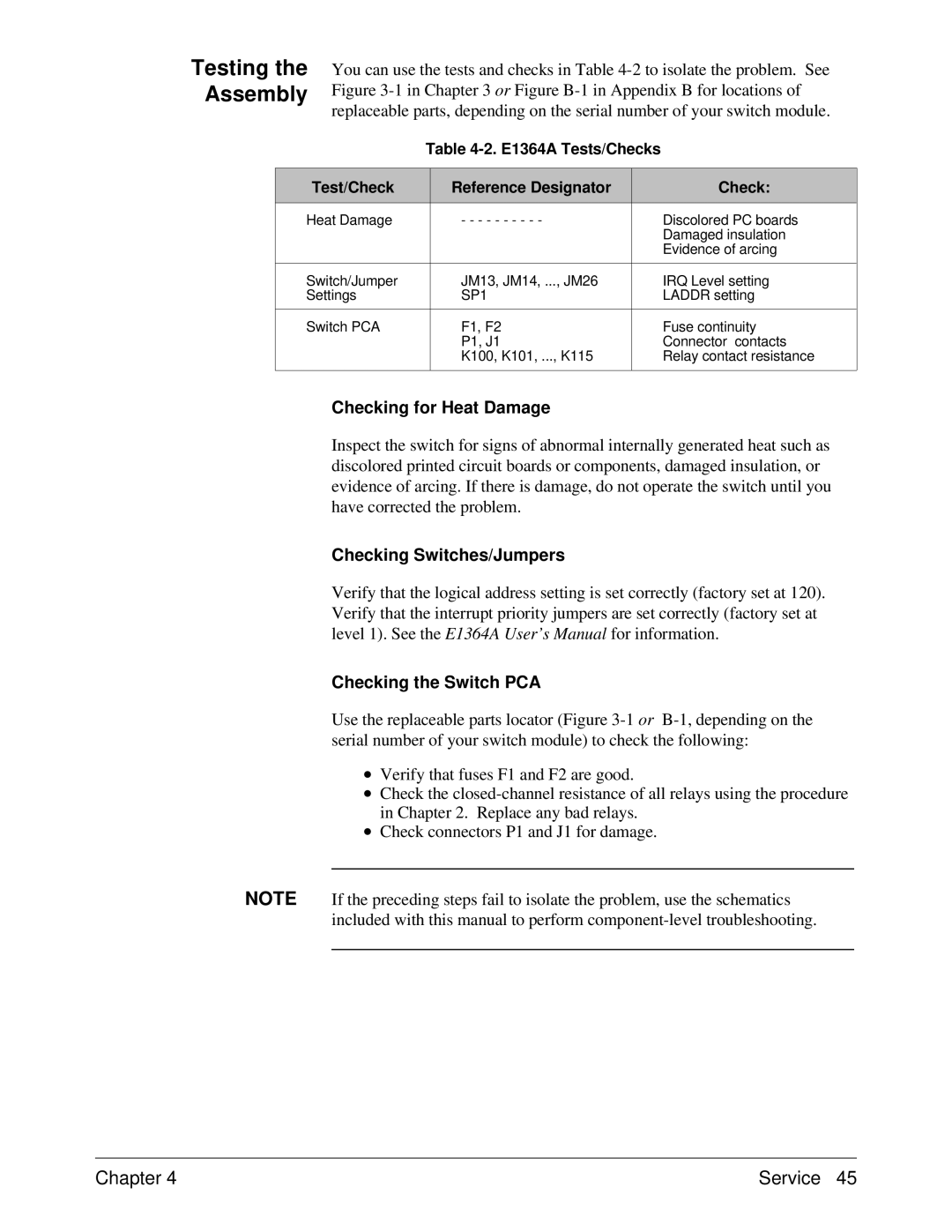

Table 4-2. E1364A Tests/Checks

Test/Check | Reference Designator | Check: |

|

|

|

Heat Damage | - - - - - - - - - - | Discolored PC boards |

|

| Damaged insulation |

|

| Evidence of arcing |

|

|

|

Switch/Jumper | JM13, JM14, ..., JM26 | IRQ Level setting |

Settings | SP1 | LADDR setting |

|

|

|

Switch PCA | F1, F2 | Fuse continuity |

| P1, J1 | Connector contacts |

| K100, K101, ..., K115 | Relay contact resistance |

|

|

|

Checking for Heat Damage

Inspect the switch for signs of abnormal internally generated heat such as discolored printed circuit boards or components, damaged insulation, or evidence of arcing. If there is damage, do not operate the switch until you have corrected the problem.

Checking Switches/Jumpers

Verify that the logical address setting is set correctly (factory set at 120). Verify that the interrupt priority jumpers are set correctly (factory set at level 1). See the E1364A User’s Manual for information.

Checking the Switch PCA

Use the replaceable parts locator (Figure

•Verify that fuses F1 and F2 are good.

•Check the

•Check connectors P1 and J1 for damage.

NOTE If the preceding steps fail to isolate the problem, use the schematics included with this manual to perform

Chapter 4 | Service 45 |