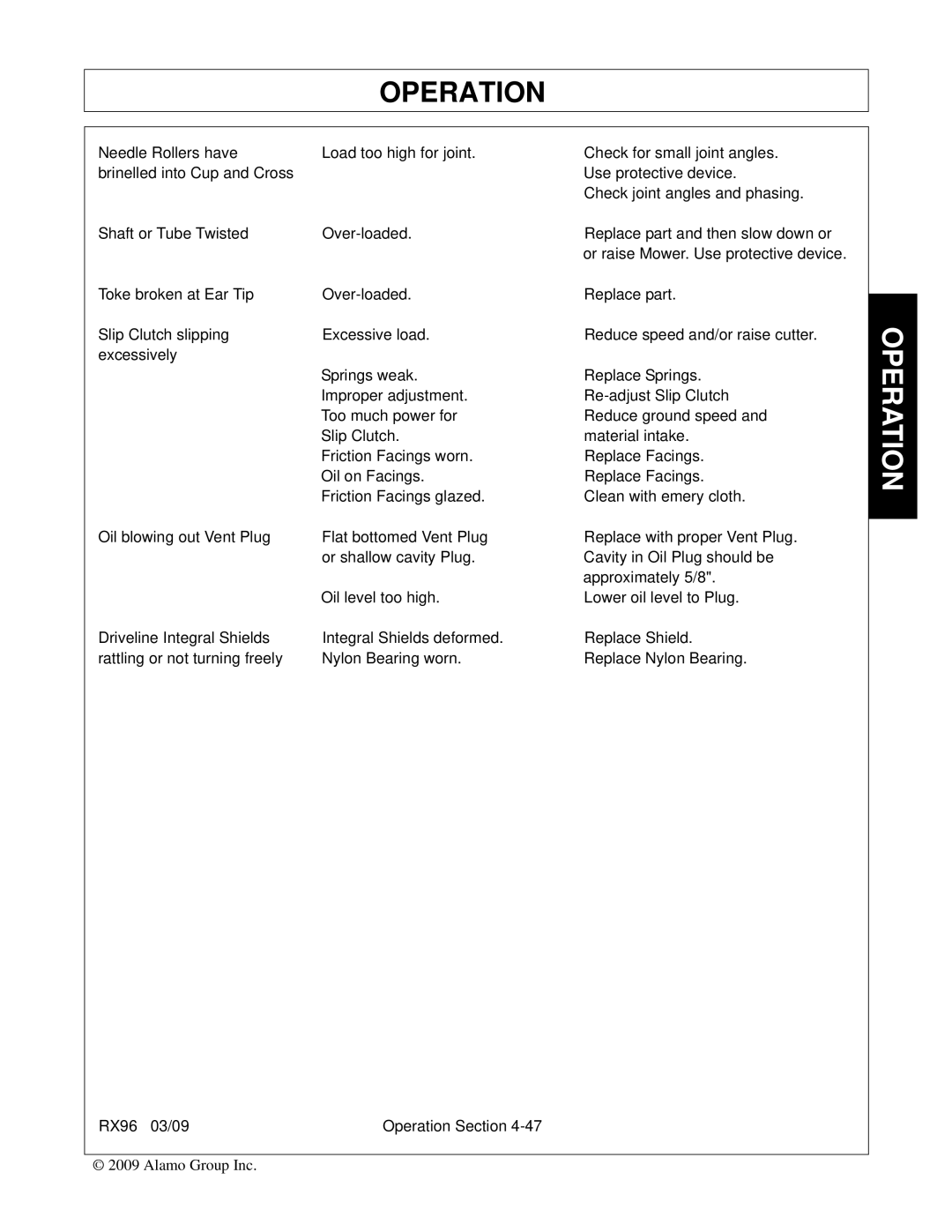

OPERATION

Needle Rollers have | Load too high for joint. | Check for small joint angles. |

brinelled into Cup and Cross |

| Use protective device. |

|

| Check joint angles and phasing. |

Shaft or Tube Twisted | Replace part and then slow down or | |

|

| or raise Mower. Use protective device. |

Toke broken at Ear Tip | Replace part. | |

Slip Clutch slipping | Excessive load. | Reduce speed and/or raise cutter. |

excessively | Springs weak. | Replace Springs. |

| ||

| Improper adjustment. | |

| Too much power for | Reduce ground speed and |

| Slip Clutch. | material intake. |

| Friction Facings worn. | Replace Facings. |

| Oil on Facings. | Replace Facings. |

| Friction Facings glazed. | Clean with emery cloth. |

Oil blowing out Vent Plug | Flat bottomed Vent Plug | Replace with proper Vent Plug. |

| or shallow cavity Plug. | Cavity in Oil Plug should be |

|

| approximately 5/8". |

| Oil level too high. | Lower oil level to Plug. |

Driveline Integral Shields | Integral Shields deformed. | Replace Shield. |

rattling or not turning freely | Nylon Bearing worn. | Replace Nylon Bearing. |

RX96 03/09 | Operation Section |

© 2009 Alamo Group Inc.