MAINTENANCE

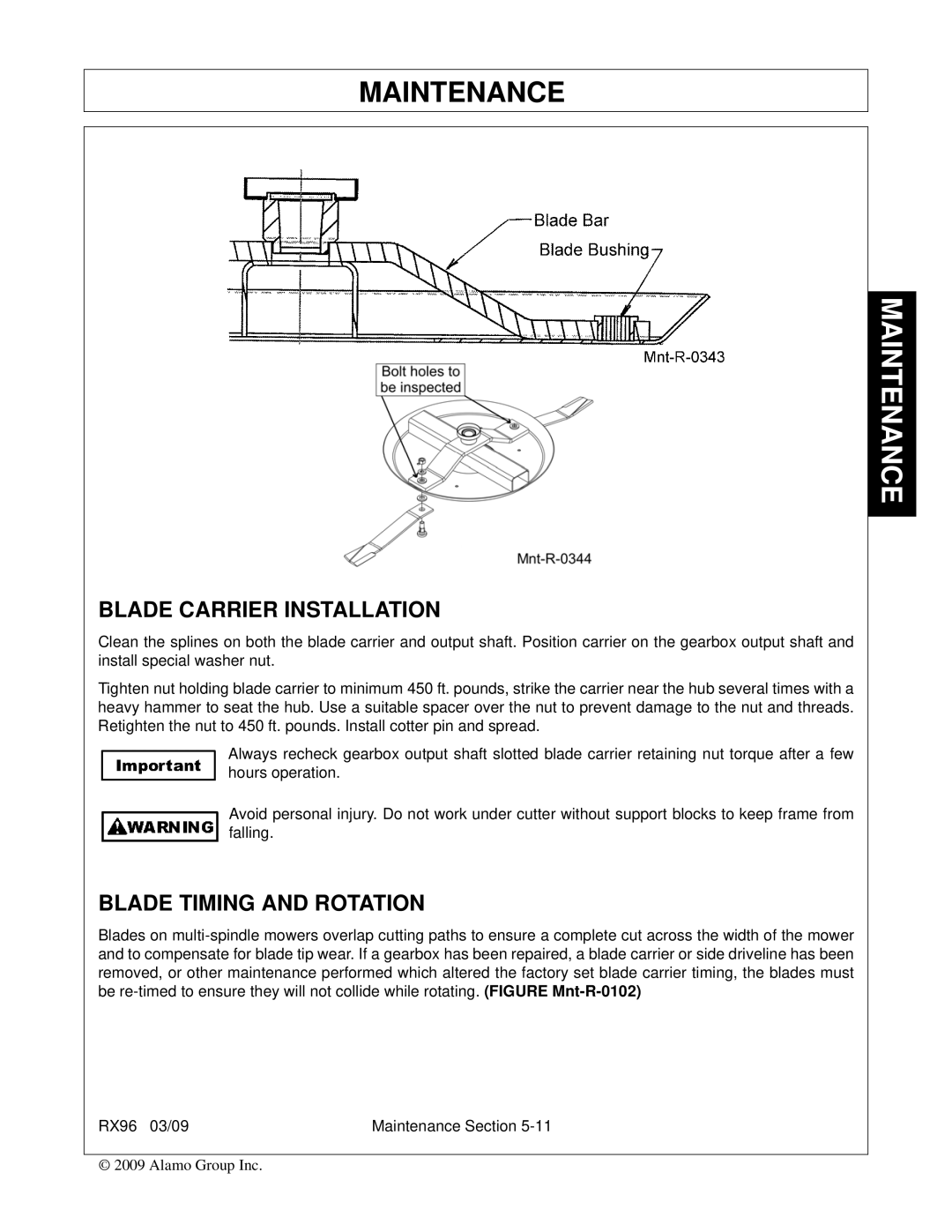

BLADE CARRIER INSTALLATION

Clean the splines on both the blade carrier and output shaft. Position carrier on the gearbox output shaft and install special washer nut.

Tighten nut holding blade carrier to minimum 450 ft. pounds, strike the carrier near the hub several times with a heavy hammer to seat the hub. Use a suitable spacer over the nut to prevent damage to the nut and threads. Retighten the nut to 450 ft. pounds. Install cotter pin and spread.

Always recheck gearbox output shaft slotted blade carrier retaining nut torque after a few hours operation.

Avoid personal injury. Do not work under cutter without support blocks to keep frame from falling.

BLADE TIMING AND ROTATION

Blades on

RX96 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.