610ESG, 2020ESG, 714ESG, 1020ESG, 1010ESG specifications

Alto-Shaam is a leading manufacturer of innovative cooking equipment, renowned for its commitment to quality and efficiency. Among its impressive lineup, the 1218ESG, 1010ESG, 1020ESG, 714ESG, and 2020ESG models stand out for their versatility and advanced technology, catering to the needs of modern kitchens.The Alto-Shaam 1218ESG is a compact yet powerful solution designed specifically for high-volume cooking. Its key features include a unique Halo Heat technology that ensures even heat distribution, eliminating the need for fans or excessive airflow. This technology maintains the food's moisture and quality, making it ideal for holding, cooking, and reheating a variety of dishes. Additionally, the 1218ESG offers touchscreen controls, allowing for easy operation and programming, as well as a wide temperature range to accommodate various cooking requirements.

Similarly, the 1010ESG is engineered for efficiency in smaller spaces without sacrificing performance. It shares the same Halo Heat technology, paired with a space-saving design. The 1010ESG features a user-friendly interface and is equipped with programmable settings, making it easy to replicate dishes consistently. Its versatility allows it to handle everything from baked goods to meats, ensuring that culinary professionals can meet diverse menu demands.

The 1020ESG, on the other hand, expands on the capabilities of the 1010ESG while maintaining a compact profile. With a slightly larger cooking chamber, it allows for more substantial portions. Users can benefit from advanced features such as programmable recipes, which streamline operations in busy kitchens. The consistent cooking performance of the 1020ESG ensures that food retains its flavor and visual appeal, enhancing the dining experience.

For those requiring a larger capacity, the Alto-Shaam 714ESG and 2020ESG models provide exceptional solutions. The 714ESG is designed for heavy-duty use, making it suitable for larger batches and high-volume operations. It includes multiple cooking racks and robust construction, providing reliability and durability in high-pressure environments.

The 2020ESG takes it a step further with its extensive features tailored for extensive food service operations. Offering advanced technology and high capacity, it is aimed at large-scale kitchens where efficiency and consistency are paramount. All these models benefit from the patented Halo Heat technology, ensuring that each dish is cooked evenly and served at the perfect temperature.

In summary, the Alto-Shaam 1218ESG, 1010ESG, 1020ESG, 714ESG, and 2020ESG represent a perfect blend of technology, reliability, and versatility. They cater to a wide range of culinary needs while ensuring the quality and consistency that food service professionals demand. With their user-friendly interfaces and innovative cooking solutions, these models continue to set the standard in the commercial cooking equipment industry.

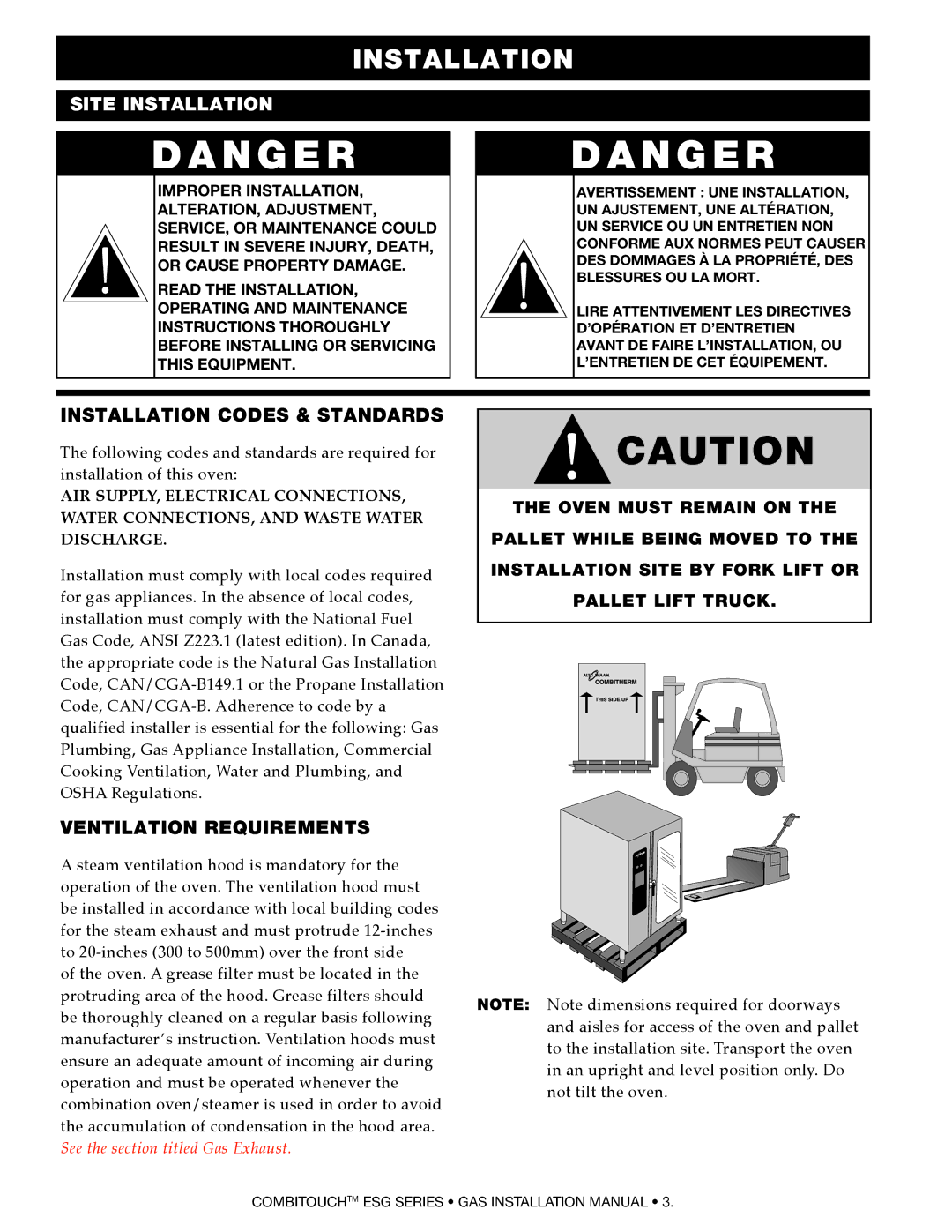

CAUTION

CAUTION