ADDENDA: LOW NOx POOL HEATERS

The Raypak Low Nox Pool Heaters are certified and tested under the ANSI Z21.56.CSA 4.7 Standards for gas fired pool heaters.

The heater should be installed to meet all local codes, the latest editions of the National Fuel Gas Code Z223.1 and the National Electrical Code, ANSI/NFPA 70.

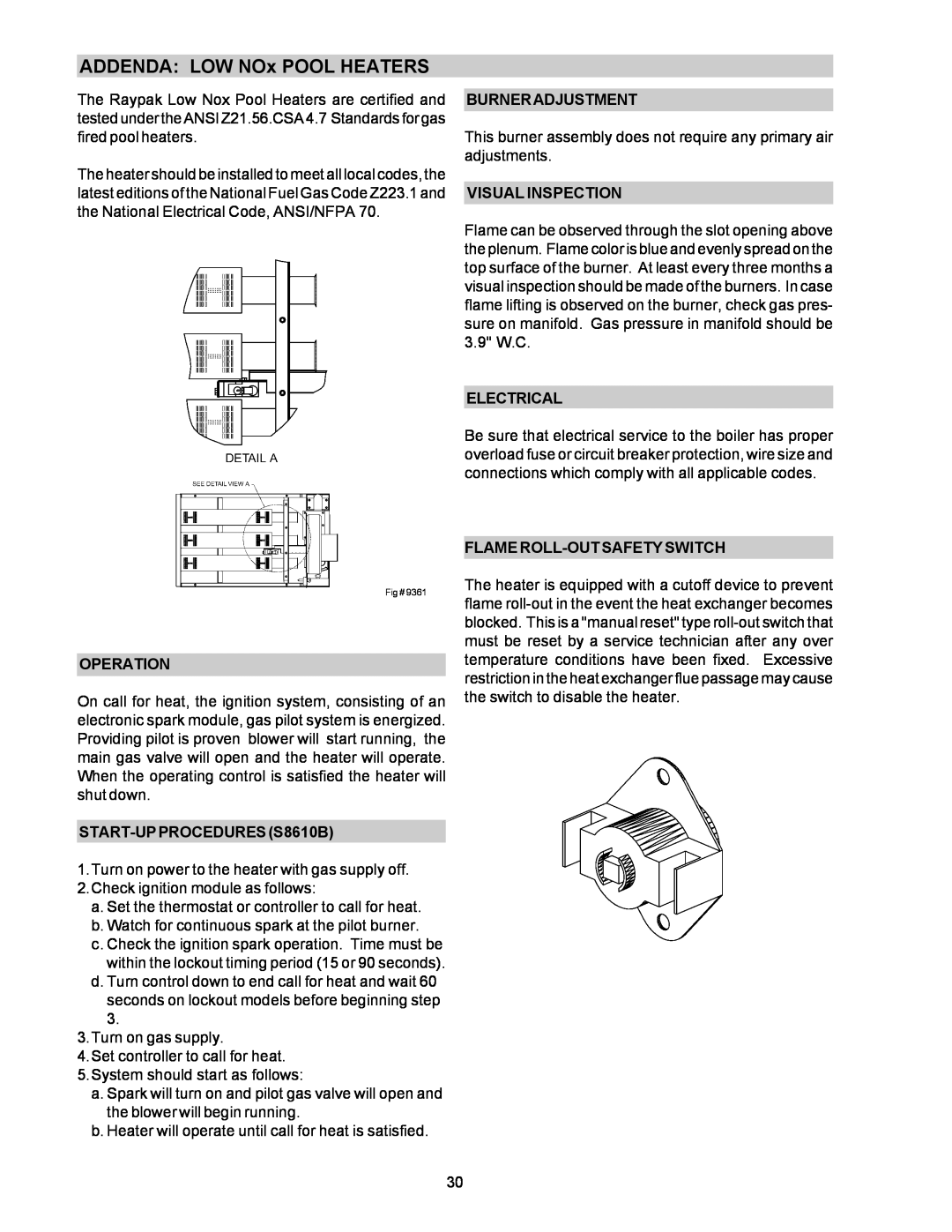

Fig # 9361

OPERATION

On call for heat, the ignition system, consisting of an electronic spark module, gas pilot system is energized. Providing pilot is proven blower will start running, the main gas valve will open and the heater will operate. When the operating control is satisfied the heater will shut down.

START-UP PROCEDURES (S8610B)

1.Turn on power to the heater with gas supply off. 2.Check ignition module as follows:

a. Set the thermostat or controller to call for heat. b. Watch for continuous spark at the pilot burner. c. Check the ignition spark operation. Time must be

within the lockout timing period (15 or 90 seconds). d. Turn control down to end call for heat and wait 60

seconds on lockout models before beginning step 3.

3.Turn on gas supply.

4.Set controller to call for heat. 5.System should start as follows:

a. Spark will turn on and pilot gas valve will open and the blower will begin running.

b. Heater will operate until call for heat is satisfied.

BURNERADJUSTMENT

This burner assembly does not require any primary air adjustments.

VISUAL INSPECTION

Flame can be observed through the slot opening above the plenum. Flame color is blue and evenly spread on the top surface of the burner. At least every three months a visual inspection should be made of the burners. In case flame lifting is observed on the burner, check gas pres- sure on manifold. Gas pressure in manifold should be 3.9" W.C.

ELECTRICAL

Be sure that electrical service to the boiler has proper overload fuse or circuit breaker protection, wire size and connections which comply with all applicable codes.

FLAME ROLL-OUT SAFETY SWITCH

The heater is equipped with a cutoff device to prevent flame

30