Baumcut 26.4 Programmable

Index

K5A

K5B

Index

Maintenance

K5C

K5D

Control Panel / Operating Elements

Programmable

Explanation of Pictographs on the Display

Chapter Survey

Chapter Survey

Introduction

Please pay special attention to the following information

Copyright

Page

Page

Machine Layout

Plan

Dimensions in mm

Place of Installation

Transport and Installation of the Machine

After the Installation of the Machine

Case of Complaints

Energy lead wire

Power Supply

Type plate

Type Plates Type plate

Safety Relevant Machine Elements

Safety Auxiliary Tools

Working Area of Operating Personnel

Placement of the warning labels Label 1 Label 2 Label 3

Placement of the warning label Durability

Safety Signs / Warning Signs

Safety Signs

Safety Precautions

Technical Data

Permissible Environmental and Operating Conditions

Hydraulic Data

Voltage supply 3 phase 360 420V, 50/60Hz

Voltage supply single phase AC 200 240, 50Hz

Voltage supply single phase AC 210 240, 60Hz

Page

Safety

Symbol

Page

Electrical energy

Start Up

Switching Machine on

Turning Machine OFF

To prevent a start-up of the machine

Program Data Display

Measurement Display and Measurement System

Page

Manual Operation

Cutting Line Indicator, Mechanical with Clamp

Setting of Measurements Backgauge Movement by Hand

Cutting Line Indicator, Optical

Actuate toggle switch 8 at main switch plate

Clamp Pressure Adjustment

Setting the Clamping Time

Clamping and Cutting

Light Barrier

Interference into the light curtain causes

To continue the cutting process

Continuation Light Barrier

D2 D4 D1 D3

Meaning of LEDs in display unit

Clamping with False Clamp Plate

Attaching false clamp plate

Removing of false clamp plate

Automatic Operation

Functions of the menu keys Key Main menu Function Survey

Basic Display Program Data

Basic Displays

Program Data Key Main Menu Function Survey

Program Information Key Program Directory

Contin. Basic Display Program Data

Press key

Basic Display Program Information

1575

Basic Display Program Directory

5VAC

Other input modes in this display

Press menu key

Basic Display Main Menu Function Survey

Cursor Movement in Basic Display

Measurement input in inches

Automatic Backgauge Adjustment through Numerical Keyboard

Program data display After 1. inputinput section shows

Backgauge moves

Deletion of a Wrong Input

Input Error Value of Nom. Backgauge Position too Low/High

Moving Backgauge to a Nominal Position Positioning

Deletion of a wrong input

Possible in all 4 basic monitor displays

Make selection Program Number

Display example

Selecting a Program

According to order number

Example

Numerical keyboard

Continuing Selecting a Program

Only in Program data display

Storage of Measurements

Two side trim on size DIN A3 Untrimmed size 31 x 43 cm

Setting Up a Cutting Program, Example

Key input

Running the program

Call program 5A Enter

Correction of an Input Error

Correcting before storing

Correcting after storing

Automatic OFF

Automatic ON/OFF

Positioning check in automatic operation

Made GO to Position

Example Setting a cutting program, example

Running a Cutting Program

After cut

Press key Program Information

Storing of Program Informations

Storing Order

End of information input

Deletion of a Step Number

Deletion of One/Several Programs

Deletion of Complete Memory

PRO

Storing of Measurements According to Printed Image

Inserting of Measurements into a Program

Calculator Functions

Overflow Indicator

ConditionsAutomatic OFF

To set backgauge to a calculated size

Using Backgauge Position of Calculations

Switching the function off

Negative Sign

Machine Functions and Additional Functions Menu Keys

Machine Functions

Additional Functions

Key Main Menu Key Main Menu includes the following functions

Machine Function Main Menu Function Survey

Select Language / Measuring Unit

Service

Select Main Menu Funtion survey

Select function Language or Measuring Unit

Calibration to compensate for knifes of different thickness

Knife Compensation

Select function Select Knife compensation

Knife change

Resting Time for Knife at BDC

Adjust time

Set counter

Maintenance Cut Counter

Preset Functions

Selection of Main Menu Correction of Current Position

Calculate basic position

Select function Preset functions Scan Reference Positionj

Continuing Preset Functions

Possible funtions in Auxiliary mode

Abortion of reference run

End of input with key

Adjustment of Display Contrast

Block Programming

Possibility of edge trim preadjusting

Example Variation 1, selection 1 Angular cut

Setting up a Block Programming

Selection of an input parameter with Block Programming

Correction of an input parameter with Block Programming

Deletion of an input parameter with Block Programming

Example Variation 1, selection Four trim cut

Enter Edge trim

Four trim cut

Four trim cut with labels

Example Variation 3, selection 3 Four trim cut with labels

Block Programming

Four-side trim with labels and trim cuts Right-hand lay side

Enter trimout measurement

Enter outside trim

Block Programming

Menu Key Additional Functions

Storage of Additional Functions with Cut Size

Subsequent Storing of Additional Functions

Erase Additional Function

List of Additional Functions

Additional function Jogging mark Operation

Ejector OFF

K5C

Menu Key Auxiliary Functions

Cut and Record

Sheet Size Tables

After program generation

Subtraction Repetition Unit

Quitt the function

Graphics OFF

K5D

Menu Key Machine Parameters

Adjustment of BDC time

Adjustment of pre-pressure time

Prepressure Time

Make selection

Knife Change

Deposit knife in knife box!! Remove knife guard

Mounting the knife

Knife Change

Knife adjustment

Adjustment of knife pre-tension

Adjusting the knife

Tighten up all knife bolts

Removing of cutting stick

Changing of cutting stick

Inserting of cutting stick

Normal Turn over

Page

Malfunctions / Breakdowns

Remedy for machine malfunctions

Electrical Malfunctions/Breakdowns

Machine functions possible in Auxiliary Mode

Start Up Breakdown Scan Reference Point/Auxiliary Mode

Breakdown Knife bar stops beneath the upper dead centre

Breakdown Clamp stops beneath the upper dead centre

Knife bar or clamp not in top dead centre

Maintenance

Basic information about servicing and maintenance work

Lubrication intervals weekly

Quantity liters 22,5

Hrs. per day equal

Cleaning of Display

Page

Service Mr./Mrs

Fax 937/492-7280

Baum USA

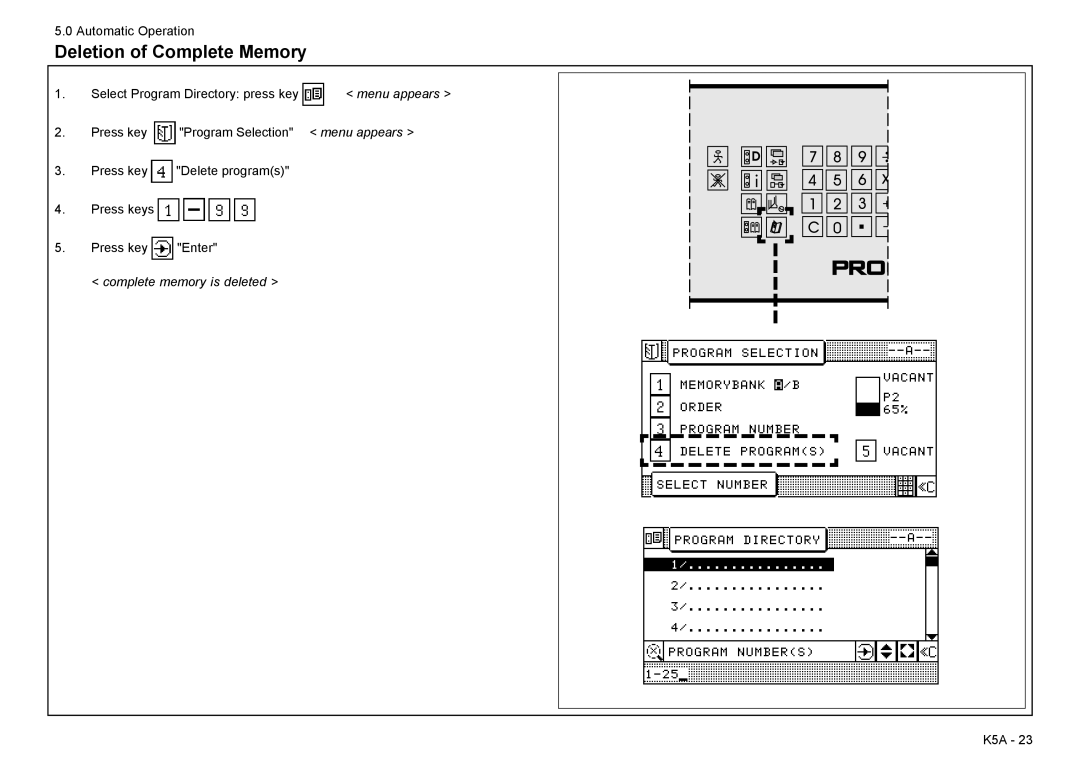

![]() "Program Selection" < menu appears >

"Program Selection" < menu appears >![]() "Delete program(s)"

"Delete program(s)"![]()

![]()

![]()

![]()

![]() "Enter"

"Enter"