until the bearing spacer and outer race are seated against the snap ring.

Install the seal(27) on tool 297674 so that the seal’s lip groove rests against the large diameter of the tool. Next install the thick bearing spacer on the tool making certain the flat side of the bearing spacer rests against the seal. (See Figures 41 E, F & G) Insert the tool with the parts installed on it through the side cover opening and using a mallet drive the seal into place.

Install the boot retainer(24) in the housing. Next install the small diameter of the boot(23) into the retainer, making certain it is fully seated within the groove formed by the retainer.

HOUSING & VALVE BODY ASSEMBLY

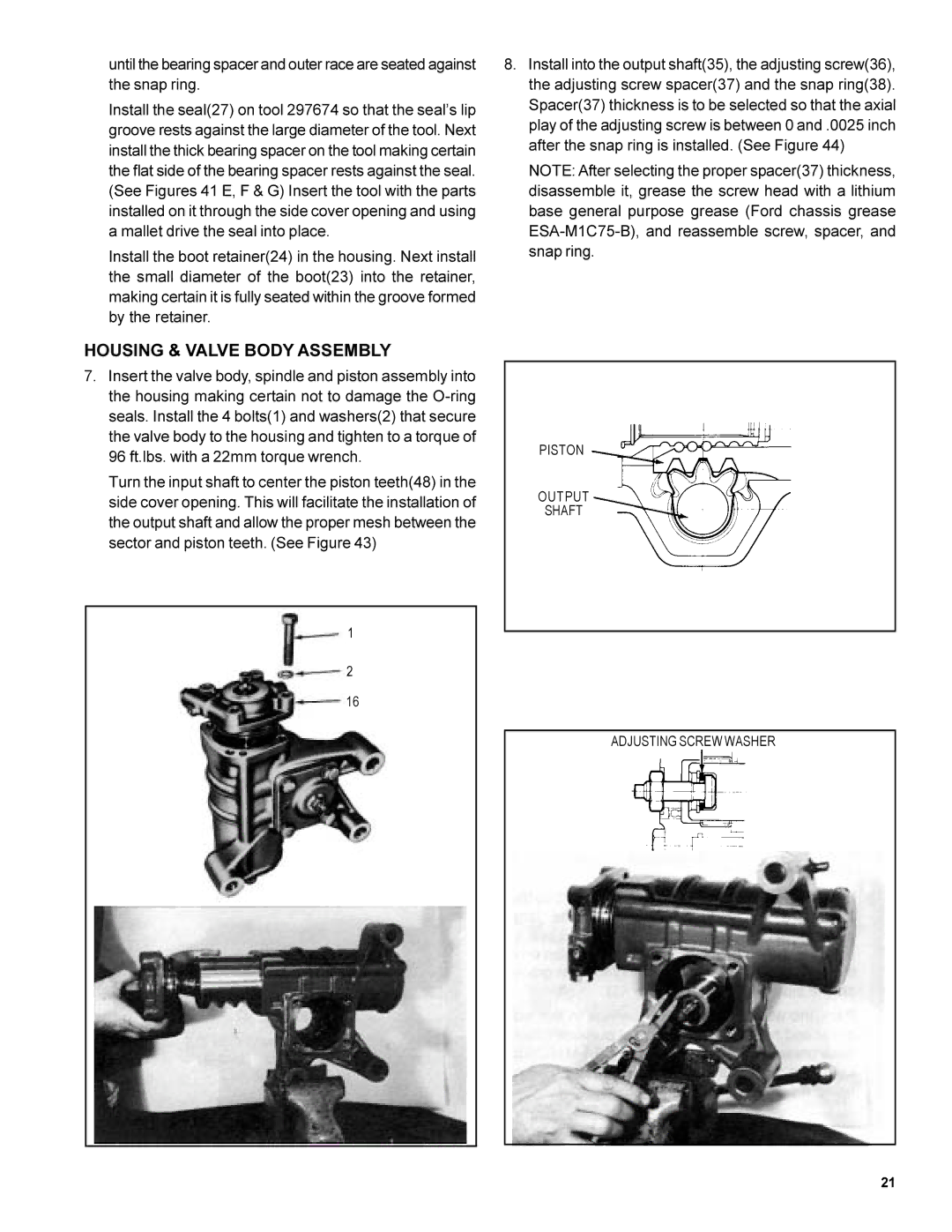

7.Insert the valve body, spindle and piston assembly into the housing making certain not to damage the

Turn the input shaft to center the piston teeth(48) in the side cover opening. This will facilitate the installation of the output shaft and allow the proper mesh between the sector and piston teeth. (See Figure 43)

1

2

16

FIGURE 42

8.Install into the output shaft(35), the adjusting screw(36), the adjusting screw spacer(37) and the snap ring(38). Spacer(37) thickness is to be selected so that the axial play of the adjusting screw is between 0 and .0025 inch after the snap ring is installed. (See Figure 44)

NOTE: After selecting the proper spacer(37) thickness, disassemble it, grease the screw head with a lithium base general purpose grease (Ford chassis grease

PISTON

OUTPUT

SHAFT

FIGURE 43

ADJUSTING SCREW WASHER

FIGURE 44

21