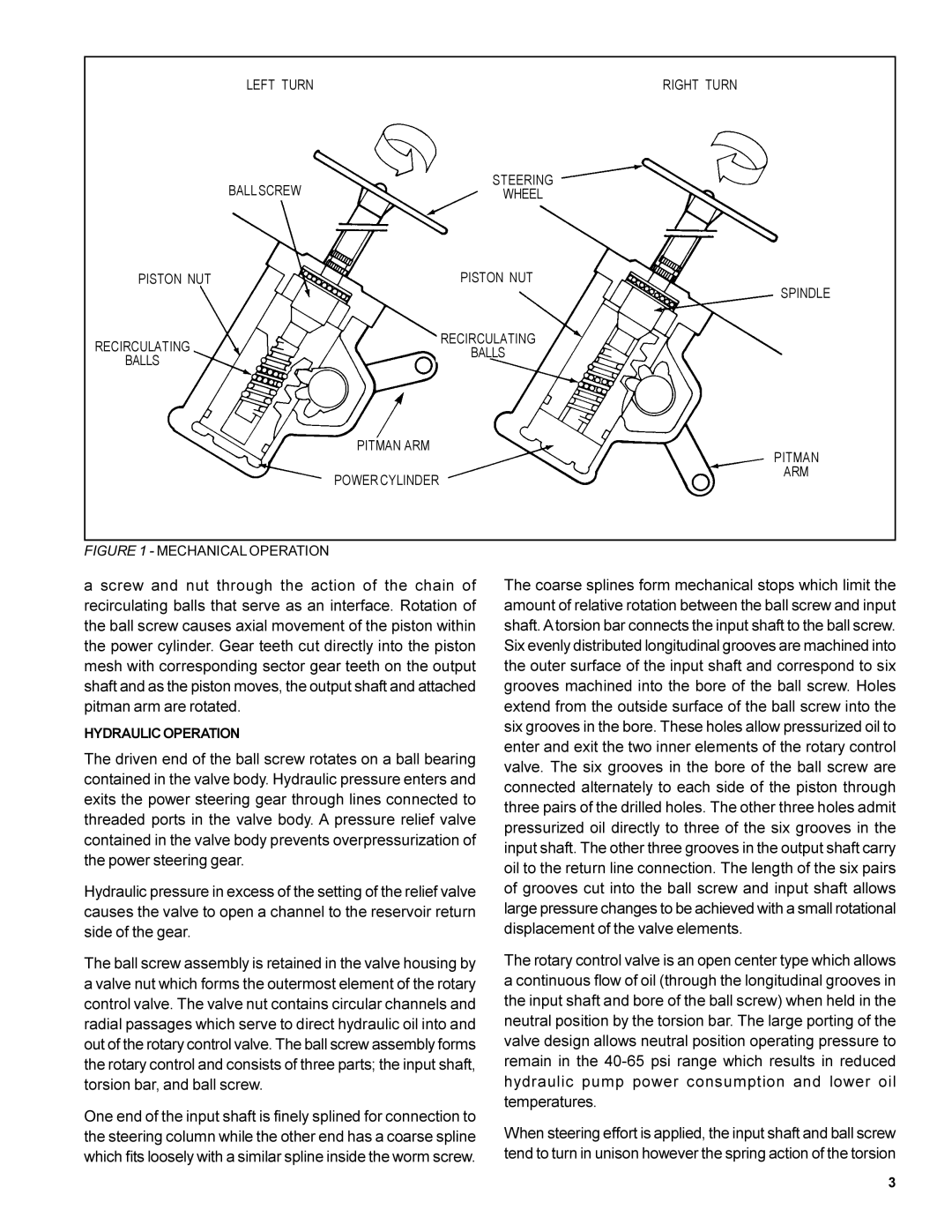

LEFT TURN | RIGHT TURN |

BALL SCREW | STEERING |

WHEEL |

PISTON NUT | PISTON NUT | |

| SPINDLE | |

RECIRCULATING | RECIRCULATING | |

BALLS | ||

BALLS | ||

|

PITMAN ARM | PITMAN |

| |

POWER CYLINDER | ARM |

|

FIGURE 1 - MECHANICAL OPERATION

a screw and nut through the action of the chain of recirculating balls that serve as an interface. Rotation of the ball screw causes axial movement of the piston within the power cylinder. Gear teeth cut directly into the piston mesh with corresponding sector gear teeth on the output shaft and as the piston moves, the output shaft and attached pitman arm are rotated.

HYDRAULIC OPERATION

The driven end of the ball screw rotates on a ball bearing contained in the valve body. Hydraulic pressure enters and exits the power steering gear through lines connected to threaded ports in the valve body. A pressure relief valve contained in the valve body prevents overpressurization of the power steering gear.

Hydraulic pressure in excess of the setting of the relief valve causes the valve to open a channel to the reservoir return side of the gear.

The ball screw assembly is retained in the valve housing by a valve nut which forms the outermost element of the rotary control valve. The valve nut contains circular channels and radial passages which serve to direct hydraulic oil into and out of the rotary control valve. The ball screw assembly forms the rotary control and consists of three parts; the input shaft, torsion bar, and ball screw.

One end of the input shaft is finely splined for connection to the steering column while the other end has a coarse spline which fits loosely with a similar spline inside the worm screw.

The coarse splines form mechanical stops which limit the amount of relative rotation between the ball screw and input shaft. A torsion bar connects the input shaft to the ball screw. Six evenly distributed longitudinal grooves are machined into the outer surface of the input shaft and correspond to six grooves machined into the bore of the ball screw. Holes extend from the outside surface of the ball screw into the six grooves in the bore. These holes allow pressurized oil to enter and exit the two inner elements of the rotary control valve. The six grooves in the bore of the ball screw are connected alternately to each side of the piston through three pairs of the drilled holes. The other three holes admit pressurized oil directly to three of the six grooves in the input shaft. The other three grooves in the output shaft carry oil to the return line connection. The length of the six pairs of grooves cut into the ball screw and input shaft allows large pressure changes to be achieved with a small rotational displacement of the valve elements.

The rotary control valve is an open center type which allows a continuous flow of oil (through the longitudinal grooves in the input shaft and bore of the ball screw) when held in the neutral position by the torsion bar. The large porting of the valve design allows neutral position operating pressure to remain in the

When steering effort is applied, the input shaft and ball screw tend to turn in unison however the spring action of the torsion

3