Saw Operations

Compound Cuts

—A “compound cut” is a

—A compound cut can be made as either a chop cut or a slide cut depending on the width of the work- piece.

—Because it may take several tries to obtain the desired compound angle, perform test cuts on scrap material before making your cut.

Follow these instructions for making your compound cut:

1.Extend the base extensions and fences on the side on which the cut will be made. (See Sliding Fences and Base Extensions on page 22.)

2.Properly position workpiece. Make sure work- piece is clamped firmly against the table or the fence.

! WARNING | Use clamping position that does not | |

interfere with operation. Before | ||

|

switching on, lower head assembly to make sure clamp clears guard and head assembly.

3.Set miter and bevel angles according to the instructions on page 24 and 25 for miter and bevel cuts.

4.Follow the procedures for either chop cut or slide cut (see page 23).

5.Wait until blade comes to a complete stop before returning head assembly to the raised position and / or removing workpiece.

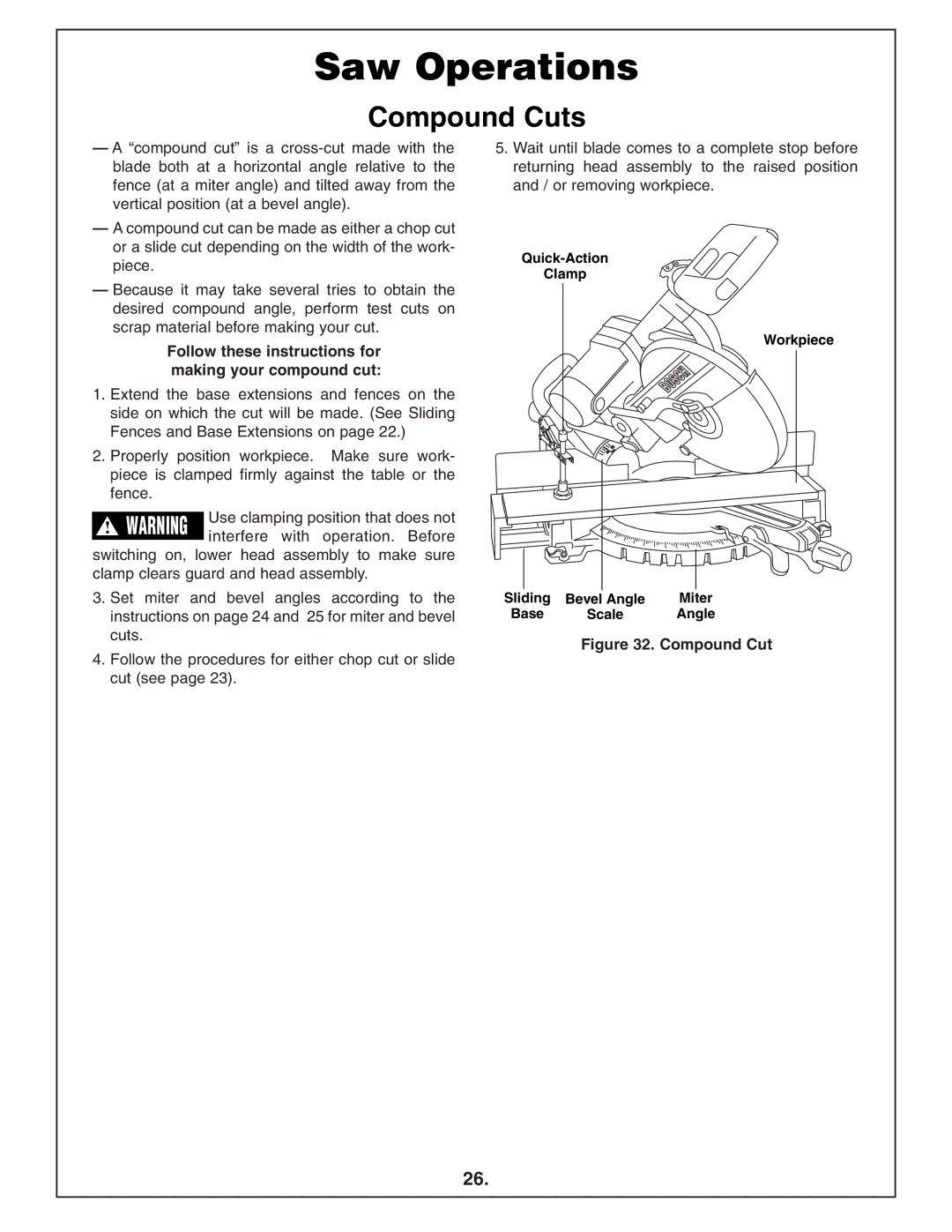

Quick-Action

Clamp

Workpiece

Sliding | Bevel Angle | Miter |

Base | Scale | Angle |

Figure 32. Compound Cut

26.