Saw Operations

Miter Cut

—A “miter cut” is a

—A miter cut is made at 0° bevel and any miter angle in the range from 52° left to 60° right.

—The miter scale shows the angle of the blade relative to the fence angle is

—Positive detents have been provided for fast and accurate mitering at 0°, 15°, 22.5°, 31.6° and 45° left and right and 60° right.

—The crown molding detents (left and right) are at 31.6° (See Cutting Crown Molding for more infor- mation page 29).

—For precision settings at angles next to the detents, use the detent override to lock out the detent. This prevents the wedge on the detent lever from slipping back into the detent.

—A miter cut can be made as either a chop cut or a slide cut, depending on the width of the work- piece.

—The kerf inserts should be as close to the blade as possible without touching the blade (see Kerf Inserts for adjustment procedures).

Follow these instructions for making your miter cut:

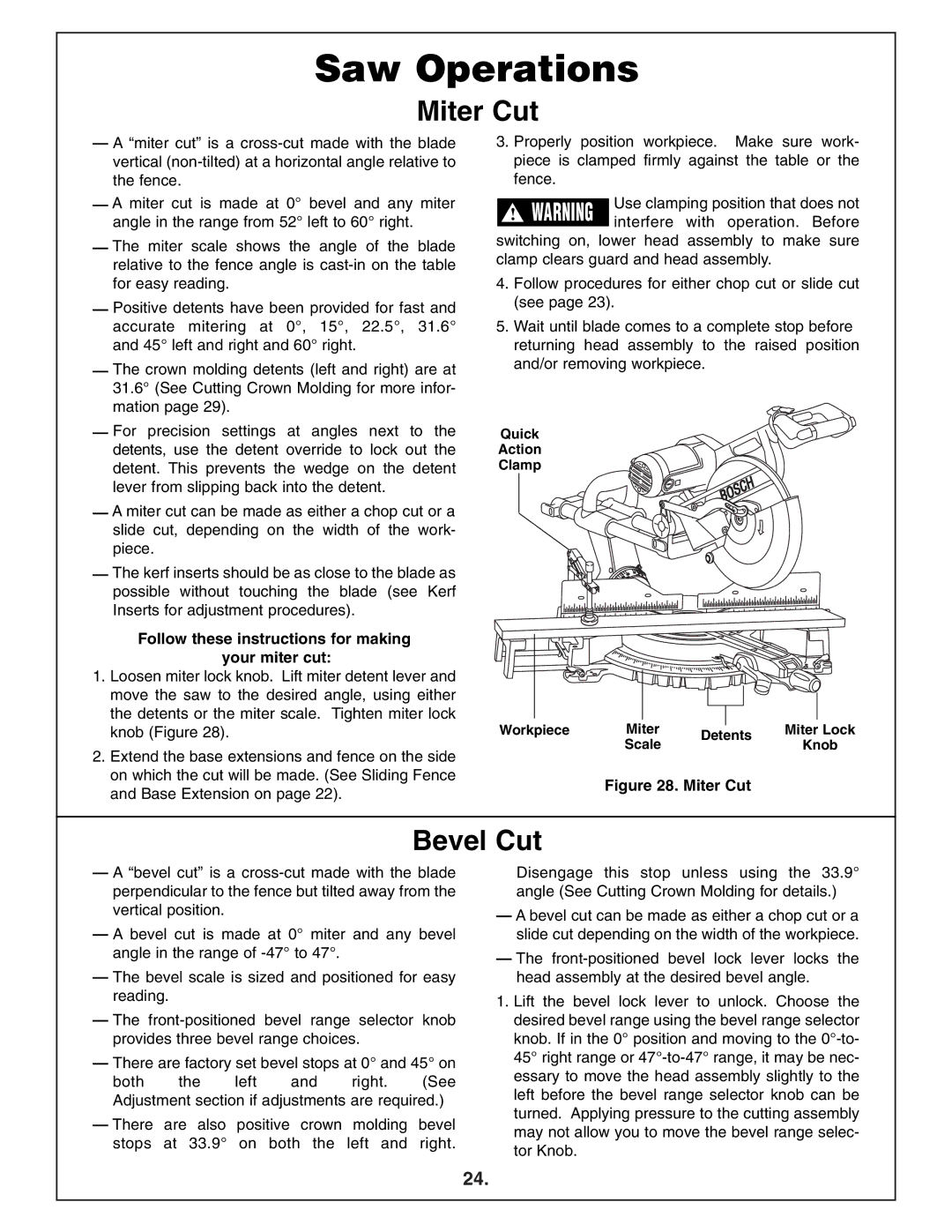

1.Loosen miter lock knob. Lift miter detent lever and move the saw to the desired angle, using either the detents or the miter scale. Tighten miter lock knob (Figure 28).

2.Extend the base extensions and fence on the side on which the cut will be made. (See Sliding Fence and Base Extension on page 22).

3.Properly position workpiece. Make sure work- piece is clamped firmly against the table or the fence.

Use clamping position that does not ! WARNING interfere with operation. Before

switching on, lower head assembly to make sure clamp clears guard and head assembly.

4. Follow procedures for either chop cut or slide cut (see page 23).

5. Wait until blade comes to a complete stop before returning head assembly to the raised position and/or removing workpiece.

Quick

Action

Clamp

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

Workpiece | Miter |

|

|

|

| Miter Lock | ||||

Detents | ||||||||||

|

| Scale | Knob | |||||||

|

|

|

|

|

| |||||

Figure 28. Miter Cut

Bevel Cut

— A “bevel cut” is a | Disengage this stop unless using the 33.9° | ||||||||

perpendicular to the fence but tilted away from the | angle (See Cutting Crown Molding for details.) | ||||||||

vertical position. |

|

|

|

|

| — A bevel cut can be made as either a chop cut or a | |||

|

|

|

|

|

|

|

| ||

— A bevel cut is made at 0° miter and any bevel | slide cut depending on the width of the workpiece. | ||||||||

angle in the range of |

|

| — The | ||||||

|

|

|

|

|

|

|

| ||

— The bevel scale is sized and positioned for easy | head assembly at the desired bevel angle. | ||||||||

reading. |

|

|

|

|

|

| 1. Lift the bevel lock lever to unlock. Choose the | ||

|

|

|

|

|

|

|

| ||

— The | desired bevel range using the bevel range selector | ||||||||

provides three bevel range choices. |

| knob. If in the 0° position and moving to the | |||||||

— There are factory set bevel stops at 0° and 45° on | 45° right range or | ||||||||

essary to move the head assembly slightly to the | |||||||||

both | the | left | and | right. | (See | ||||

left before the bevel range selector knob can be | |||||||||

Adjustment section if adjustments are required.) | |||||||||

turned. Applying pressure to the cutting assembly | |||||||||

— There | are | also | positive | crown | molding | bevel | |||

may not allow you to move the bevel range selec- | |||||||||

stops | at | 33.9° | on | both | the | left and | right. | ||

tor Knob. | |||||||||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| 24. | |