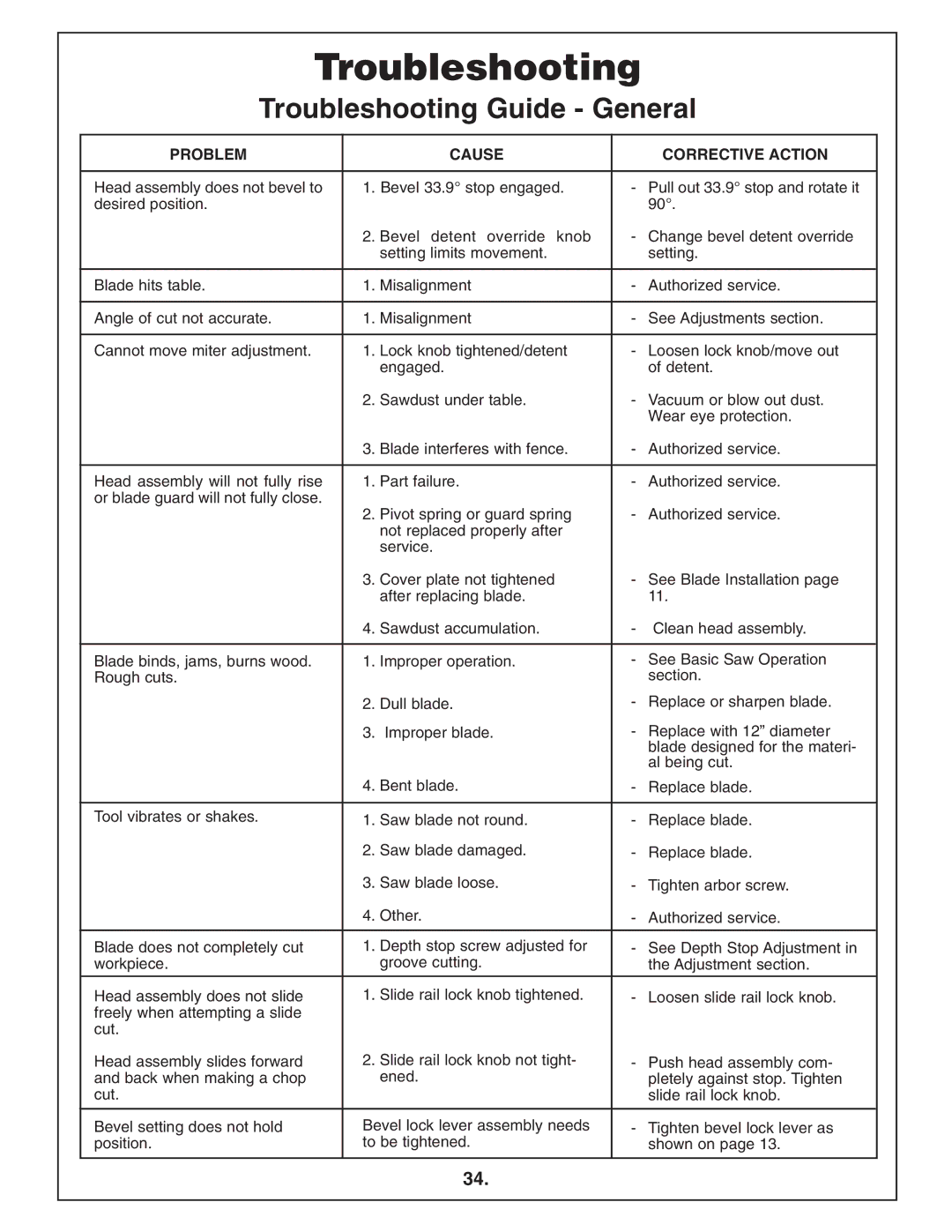

Troubleshooting

Troubleshooting Guide - General

PROBLEM |

| CAUSE |

| CORRECTIVE ACTION |

|

|

| ||

Head assembly does not bevel to | 1. Bevel 33.9° stop engaged. | - Pull out 33.9° stop and rotate it | ||

desired position. |

|

|

| 90°. |

| 2. | Bevel detent override knob | - Change bevel detent override | |

|

| setting limits movement. |

| setting. |

|

|

|

|

|

Blade hits table. | 1. | Misalignment | - | Authorized service. |

|

|

|

|

|

Angle of cut not accurate. | 1. | Misalignment | - | See Adjustments section. |

|

|

|

| |

Cannot move miter adjustment. | 1. | Lock knob tightened/detent | - Loosen lock knob/move out | |

|

| engaged. |

| of detent. |

| 2. | Sawdust under table. | - Vacuum or blow out dust. | |

|

|

|

| Wear eye protection. |

| 3. | Blade interferes with fence. | - | Authorized service. |

|

|

|

|

|

Head assembly will not fully rise | 1. | Part failure. | - | Authorized service. |

or blade guard will not fully close. | 2. | Pivot spring or guard spring | - | Authorized service. |

| ||||

|

| not replaced properly after |

|

|

|

| service. |

|

|

| 3. | Cover plate not tightened | - See Blade Installation page | |

|

| after replacing blade. |

| 11. |

| 4. | Sawdust accumulation. | - | Clean head assembly. |

|

|

|

| |

Blade binds, jams, burns wood. | 1. | Improper operation. | - See Basic Saw Operation | |

Rough cuts. |

|

|

| section. |

| 2. | Dull blade. | - Replace or sharpen blade. | |

| 3. | Improper blade. | - Replace with 12” diameter | |

|

|

|

| blade designed for the materi- |

|

|

|

| al being cut. |

| 4. | Bent blade. | - | Replace blade. |

|

|

|

|

|

Tool vibrates or shakes. | 1. | Saw blade not round. | - | Replace blade. |

| 2. | Saw blade damaged. | - | Replace blade. |

| 3. | Saw blade loose. | - | Tighten arbor screw. |

| 4. | Other. | - | Authorized service. |

|

|

|

| |

Blade does not completely cut | 1. | Depth stop screw adjusted for | - See Depth Stop Adjustment in | |

workpiece. |

| groove cutting. |

| the Adjustment section. |

|

|

|

| |

Head assembly does not slide | 1. | Slide rail lock knob tightened. | - Loosen slide rail lock knob. | |

freely when attempting a slide |

|

|

|

|

cut. |

|

|

|

|

Head assembly slides forward | 2. | Slide rail lock knob not tight- | - Push head assembly com- | |

and back when making a chop |

| ened. |

| pletely against stop. Tighten |

cut. |

|

|

| slide rail lock knob. |

|

|

| ||

Bevel setting does not hold | Bevel lock lever assembly needs | - Tighten bevel lock lever as | ||

position. | to be tightened. |

| shown on page 13. | |

|

|

|

|

|

34.