Installing Hoses

![]()

![]()

![]()

![]()

![]()

![]() Risk of unsafe operation. Firmly grasp hose in hand when installing or disconnec- ting to prevent hose whip.

Risk of unsafe operation. Firmly grasp hose in hand when installing or disconnec- ting to prevent hose whip.

1.Ensure Regulated Pressure Gauge (C) reads 0 psi.

2.Grasp the hose at the Quick Connect (E) plug and push the plug into the Quick Connect (E) body. Coupler will snap into place.

3.Grasp the hose and pull to ensure coupler is seated.

Disconnecting Hoses

![]()

![]()

![]()

![]()

![]()

![]() Risk of unsafe operation. Firmly grasp hose in hand when installing or disconnec- ting to prevent hose whip.

Risk of unsafe operation. Firmly grasp hose in hand when installing or disconnec- ting to prevent hose whip.

1.Ensure Regulated Pressure Gauge (C) reads 0 psi.

2.Pull coupler on Quick Connect (E) body back to release Quick Connect (E) plug on hose.

Lubrication and Oil

![]()

![]()

![]()

![]()

![]() The compressor was shipped with oil in the crankcase. Closely follow Initial

The compressor was shipped with oil in the crankcase. Closely follow Initial

![]()

![]()

![]()

![]()

![]()

1.Place unit on a level surface.

2.Remove the crankcase plug used for shipping. This is installed in Dipstick (J) hole. NOTE: See Specifications for pump oil capacity.

![]()

![]()

![]()

![]()

![]() Risk of unsafe operation. Overfilling with oil will cause premature compressor failure. Do not overfill.

Risk of unsafe operation. Overfilling with oil will cause premature compressor failure. Do not overfill.

3. Install Dipstick (J) provided with compressor.

Grounding Instructions

![]() Risk of electrical shock. In the event of a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

Risk of electrical shock. In the event of a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

The portable air compressor is equipped with a cord having a grounding wire with an appropriate grounding plug.

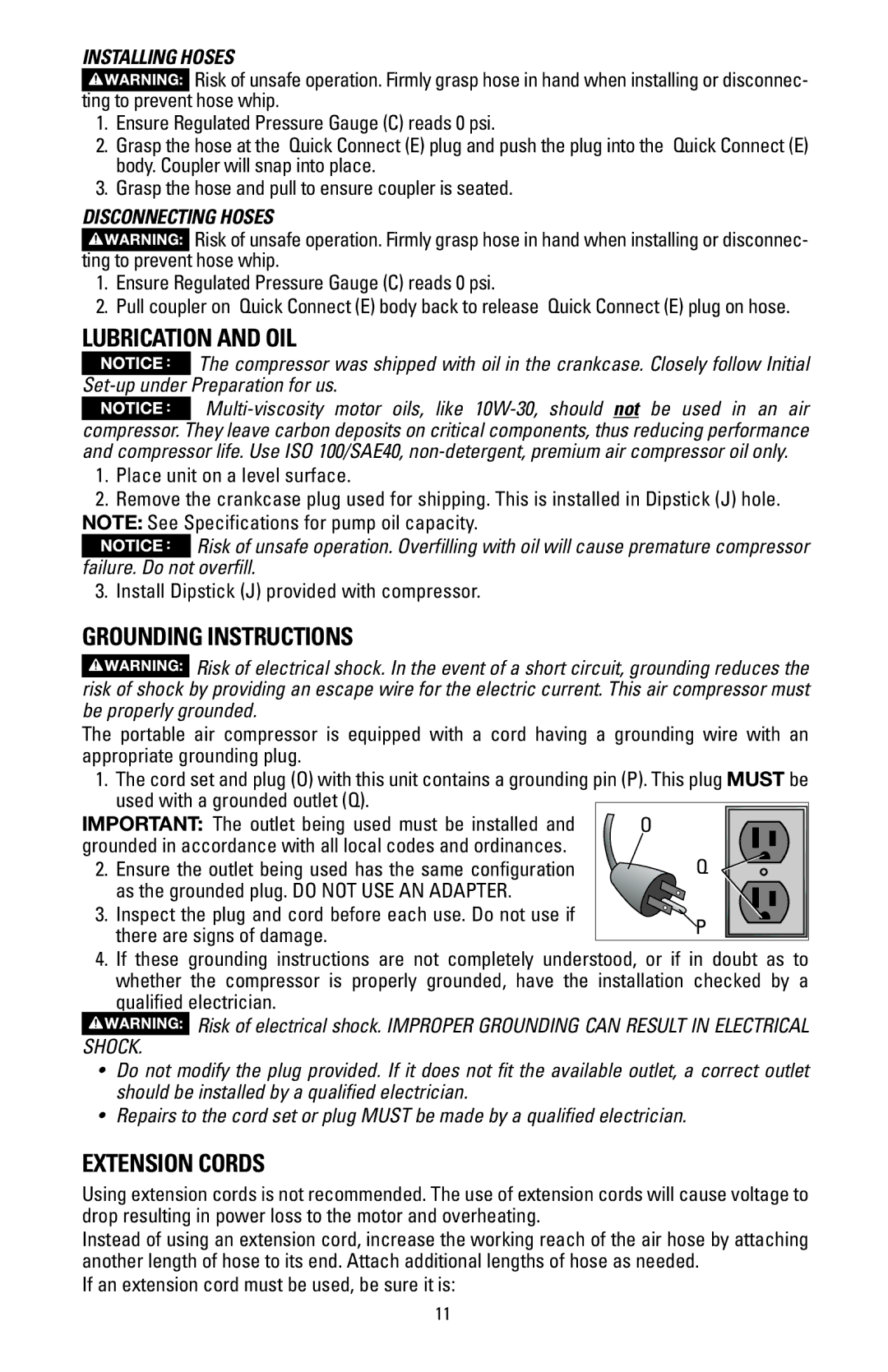

1.The cord set and plug (O) with this unit contains a grounding pin (P). This plug MUST be used with a grounded outlet (Q).

IMPORTANT: The outlet being used must be installed and |

| O |

|

|

|

|

| |

grounded in accordance with all local codes and ordinances. |

|

| Q |

|

|

|

| |

|

|

|

|

|

| |||

2. | Ensure the outlet being used has the same configuration |

|

|

|

|

|

| |

| as the grounded plug. DO NOT USE AN ADAPTER. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

3. | Inspect the plug and cord before each use. Do not use if |

|

| P |

|

|

|

|

| there are signs of damage. |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

4.If these grounding instructions are not completely understood, or if in doubt as to whether the compressor is properly grounded, have the installation checked by a qualified electrician.

![]()

![]()

![]()

![]()

![]()

![]() Risk of electrical shock. IMPROPER GROUNDING CAN RESULT IN ELECTRICAL SHOCK.

Risk of electrical shock. IMPROPER GROUNDING CAN RESULT IN ELECTRICAL SHOCK.

•Do not modify the plug provided. If it does not fit the available outlet, a correct outlet should be installed by a qualified electrician.

•Repairs to the cord set or plug MUST be made by a qualified electrician.

Extension Cords

Using extension cords is not recommended. The use of extension cords will cause voltage to drop resulting in power loss to the motor and overheating.

Instead of using an extension cord, increase the working reach of the air hose by attaching another length of hose to its end. Attach additional lengths of hose as needed.

If an extension cord must be used, be sure it is:

11