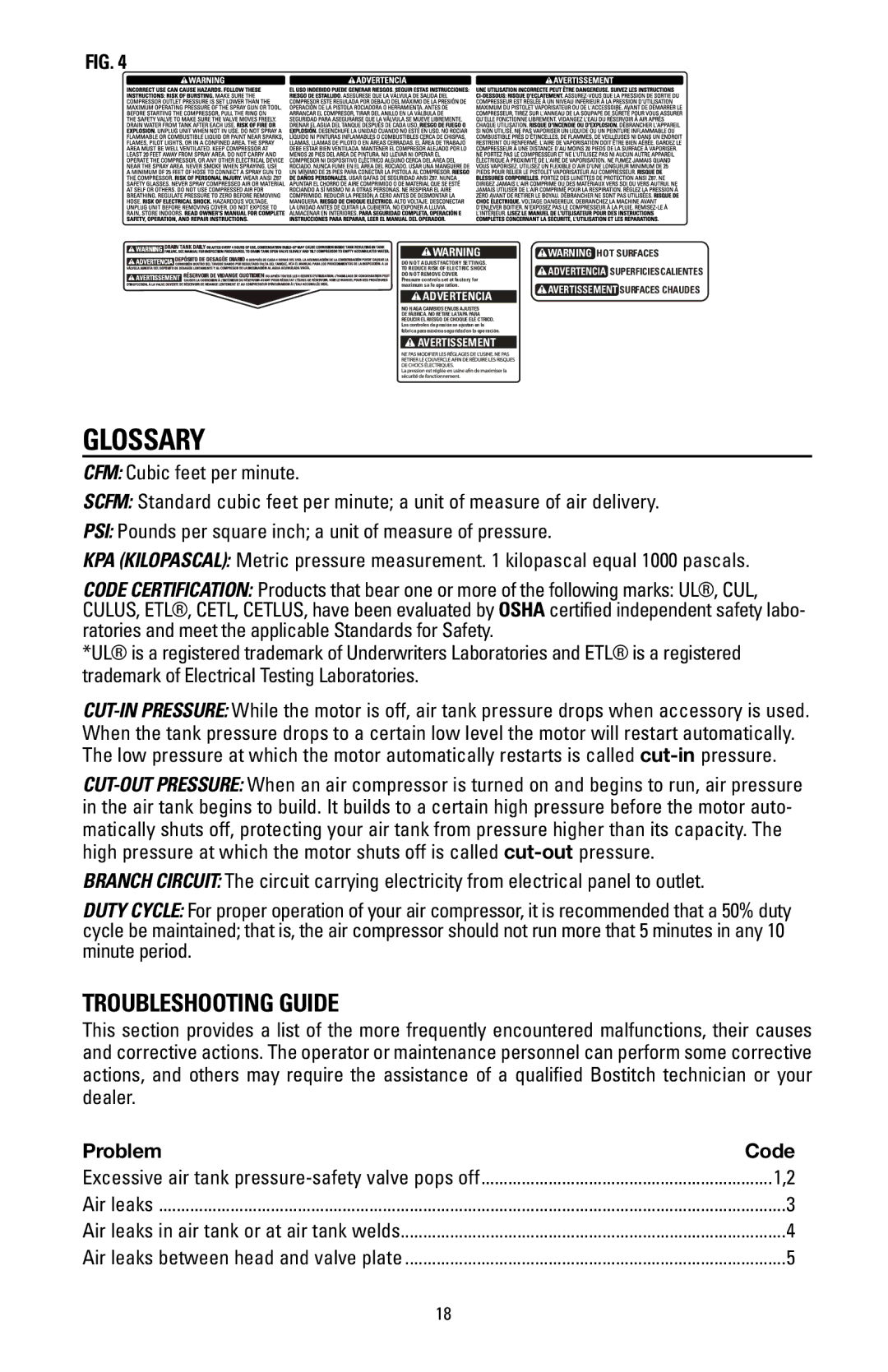

FIG. 4

![]() WARNING

WARNING

DO NOT ADJUSTFACTORY SETTINGS. TO REDUCE RISK OF ELECTRIC SHOCK DO NOT REMOVE COVER.

Pressure controls set at factory for maximum sa fe operation.

ADVERTENCIA

ADVERTENCIA

NO HAGA CAMBIOS ENLOS AJUSTES DE FÁBRICA. NO RETIRE LATAPA PARA REDUCIR EL RIESGO DE CHOQUE ELÉ CTRICO. Los controles de presión se ajustan en la fábrica para máxima seguridad en la ope ración.

![]()

![]() AVERTISSEMENT

AVERTISSEMENT

![]() WARNING HOT SURFACES

WARNING HOT SURFACES

![]() ADVERTENCIA SUPERFICIESCALIENTES

ADVERTENCIA SUPERFICIESCALIENTES ![]() AVERTISSEMENT SURFACES CHAUDES

AVERTISSEMENT SURFACES CHAUDES

Glossary

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSI: Pounds per square inch; a unit of measure of pressure.

kPa (kilopascal): Metric pressure measurement. 1 kilopascal equal 1000 pascals.

Code Certification: Products that bear one or more of the following marks: UL®, CUL, CULUS, ETL®, CETL, CETLUS, have been evaluated by OSHA certified independent safety labo- ratories and meet the applicable Standards for Safety.

*UL® is a registered trademark of Underwriters Laboratories and ETL® is a registered trademark of Electrical Testing Laboratories.

Branch Circuit: The circuit carrying electricity from electrical panel to outlet.

Duty Cycle: For proper operation of your air compressor, it is recommended that a 50% duty cycle be maintained; that is, the air compressor should not run more that 5 minutes in any 10 minute period.

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified Bostitch technician or your dealer.

Problem | Code |

Excessive air tank | .................................................................1,2 |

Air leaks | 3 |

Air leaks in air tank or at air tank welds | 4 |

Air leaks between head and valve plate | 5 |

18