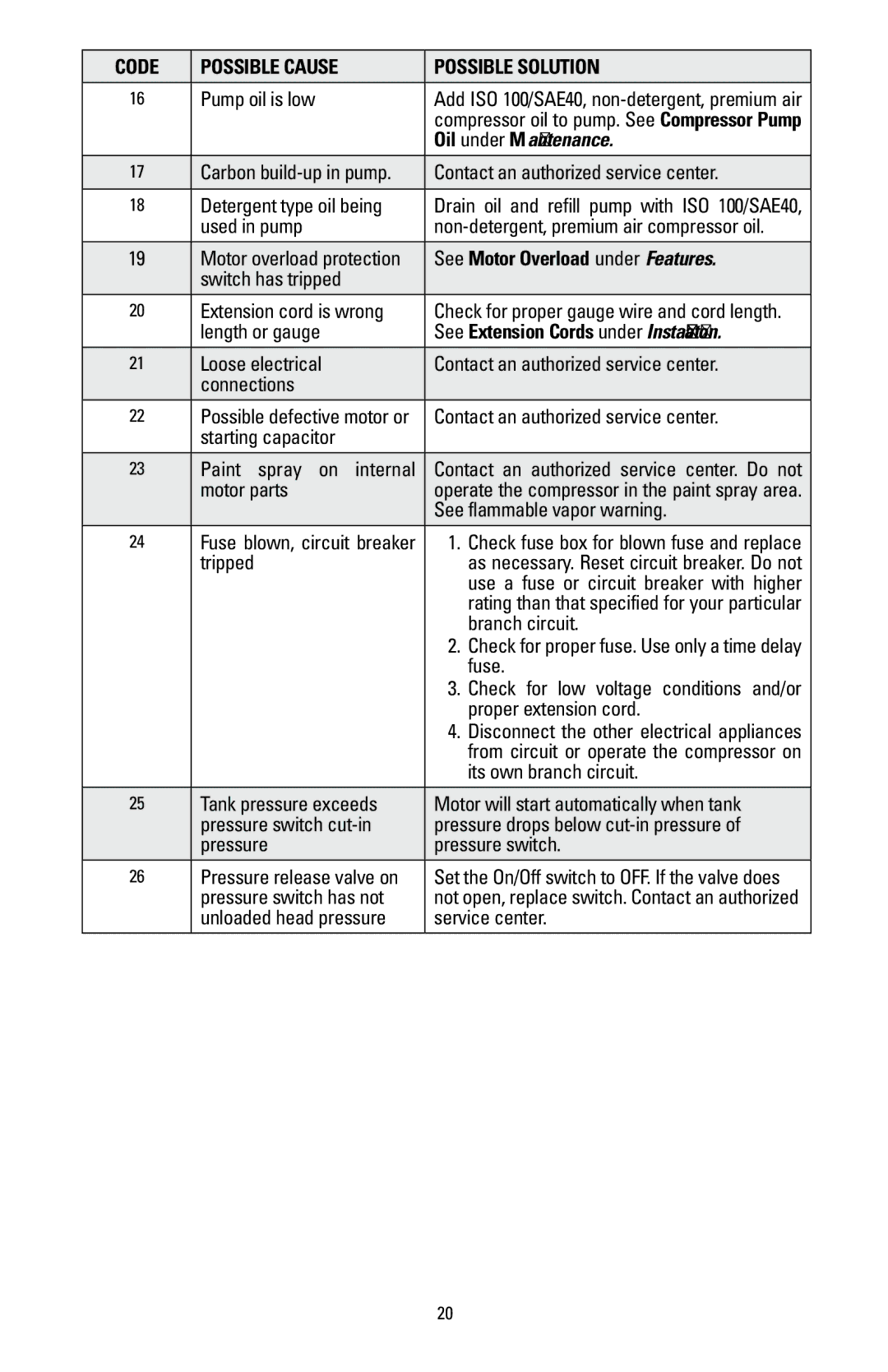

Code | possible cause | POSSIBLE SOLUTION |

|

|

|

16 | Pump oil is low | Add ISO 100/SAE40, |

|

| compressor oil to pump. See Compressor Pump |

|

| Oil under Maintenance. |

17 | Carbon | Contact an authorized service center. |

18Detergent type oil being Drain oil and refill pump with ISO 100/SAE40,

| used in pump | |

|

|

|

19 | Motor overload protection | See Motor Overload under Features. |

| switch has tripped |

|

20Extension cord is wrong Check for proper gauge wire and cord length.

| length or gauge | See Extension Cords under Installation. |

|

|

|

21 | Loose electrical | Contact an authorized service center. |

| connections |

|

22 | Possible defective motor or | Contact an authorized service center. |

| starting capacitor |

|

23Paint spray on internal Contact an authorized service center. Do not

| motor parts | operate the compressor in the paint spray area. |

|

| See flammable vapor warning. |

24 | Fuse blown, circuit breaker | 1. Check fuse box for blown fuse and replace |

| tripped | as necessary. Reset circuit breaker. Do not |

|

| use a fuse or circuit breaker with higher |

|

| rating than that specified for your particular |

|

| branch circuit. |

|

| 2. Check for proper fuse. Use only a time delay |

|

| fuse. |

|

| 3. Check for low voltage conditions and/or |

|

| proper extension cord. |

|

| 4. Disconnect the other electrical appliances |

|

| from circuit or operate the compressor on |

|

| its own branch circuit. |

25 | Tank pressure exceeds | Motor will start automatically when tank |

| pressure switch | pressure drops below |

| pressure | pressure switch. |

26 | Pressure release valve on | Set the On/Off switch to OFF. If the valve does |

| pressure switch has not | not open, replace switch. Contact an authorized |

| unloaded head pressure | service center. |

20