![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Risk of bursting. Drain air tank daily. Water will condense in air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

Risk of bursting. Drain air tank daily. Water will condense in air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

5.Allow the compressor to cool down.

6.Wipe air compressor clean and store in a safe,

Maintenance

The following procedures must be followed when maintenance or service is performed on the air compressor.

1.Ensure On/Off switch is in the OFF position.

2.Remove air compressor plug from outlet.

3.Drain air tank.

4.Allow air compressor to cool down before starting service.

NOTE: All compressed air systems contain maintenance parts (e.g., oil, filters, separators) that are periodically replaced. These used parts may contain substances that are regulated and must be disposed of in accordance with local, state, and federal laws and regulations.

NOTE: Take note of the positions and locations of parts during disassembly to make reassembly easier.

NOTE: Any service operations not included in this section should be performed by a BOSTITCH factory service center or a BOSTITCH authorized service center.

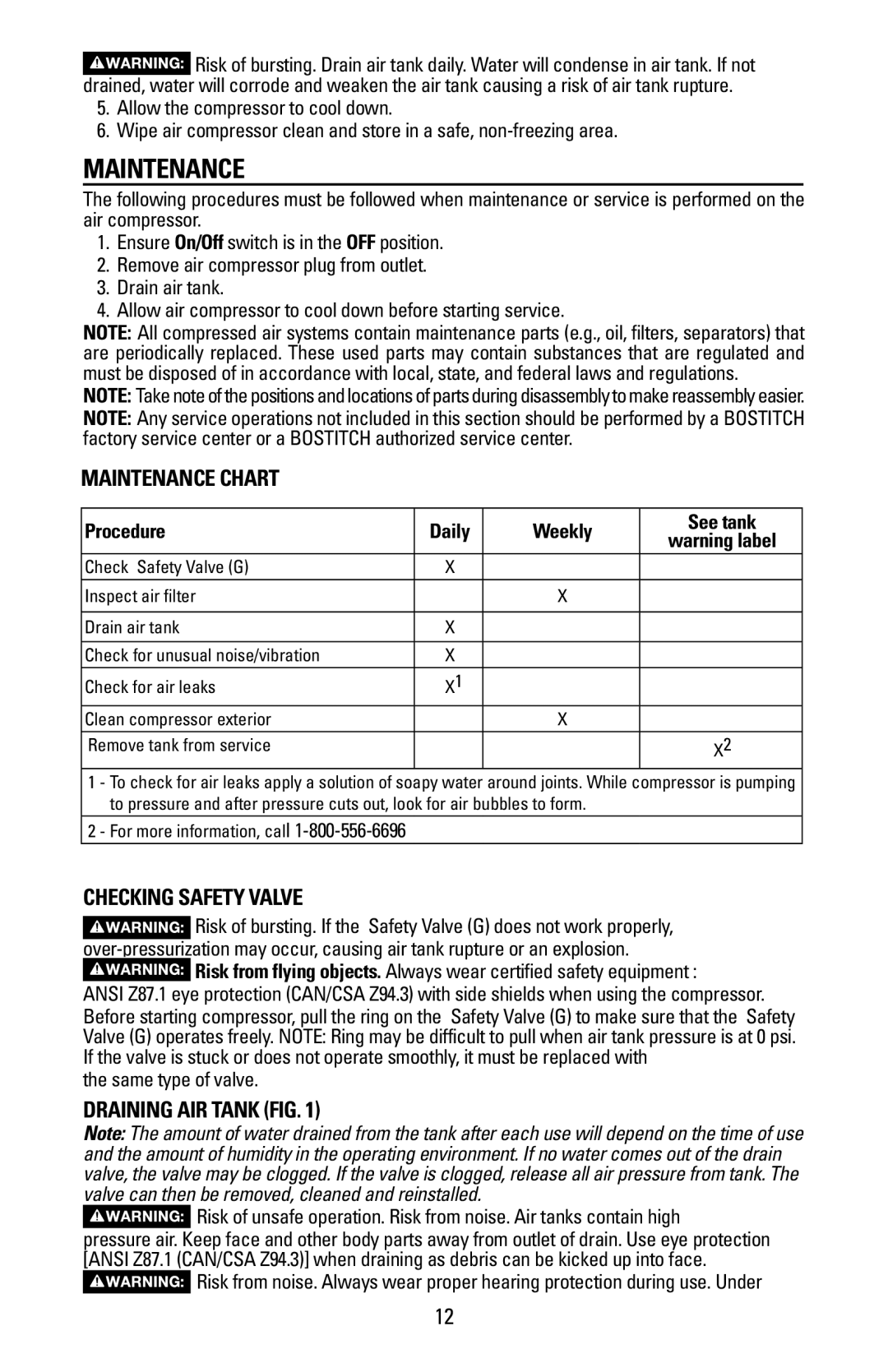

Maintenance Chart

Procedure | Daily | Weekly | See tank | |

warning label | ||||

|

|

| ||

Check Safety Valve (G) | X |

|

| |

Inspect air filter |

| X |

| |

|

|

|

| |

Drain air tank | X |

|

| |

|

|

|

| |

Check for unusual noise/vibration | X |

|

| |

Check for air leaks | X1 |

|

| |

Clean compressor exterior |

| X |

| |

Remove tank from service |

|

| X2 |

1 - To check for air leaks apply a solution of soapy water around joints. While compressor is pumping to pressure and after pressure cuts out, look for air bubbles to form.

2 - For more information, call

Checking Safety Valve

![]()

![]()

![]()

![]()

![]()

![]() Risk of bursting. If the Safety Valve (G) does not work properly,

Risk of bursting. If the Safety Valve (G) does not work properly,

Risk from flying objects. Always wear certified safety equipment :

ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields when using the compressor.

Before starting compressor, pull the ring on the Safety Valve (G) to make sure that the Safety Valve (G) operates freely. NOTE: Ring may be difficult to pull when air tank pressure is at 0 psi. If the valve is stuck or does not operate smoothly, it must be replaced with

the same type of valve.

Draining Air Tank (Fig. 1)

Note: The amount of water drained from the tank after each use will depend on the time of use and the amount of humidity in the operating environment. If no water comes out of the drain valve, the valve may be clogged. If the valve is clogged, release all air pressure from tank. The valve can then be removed, cleaned and reinstalled.

Risk of unsafe operation. Risk from noise. Air tanks contain high

pressure air. Keep face and other body parts away from outlet of drain. Use eye protection [ANSI Z87.1 (CAN/CSA Z94.3)] when draining as debris can be kicked up into face.

![]() Risk from noise. Always wear proper hearing protection during use. Under

Risk from noise. Always wear proper hearing protection during use. Under

12