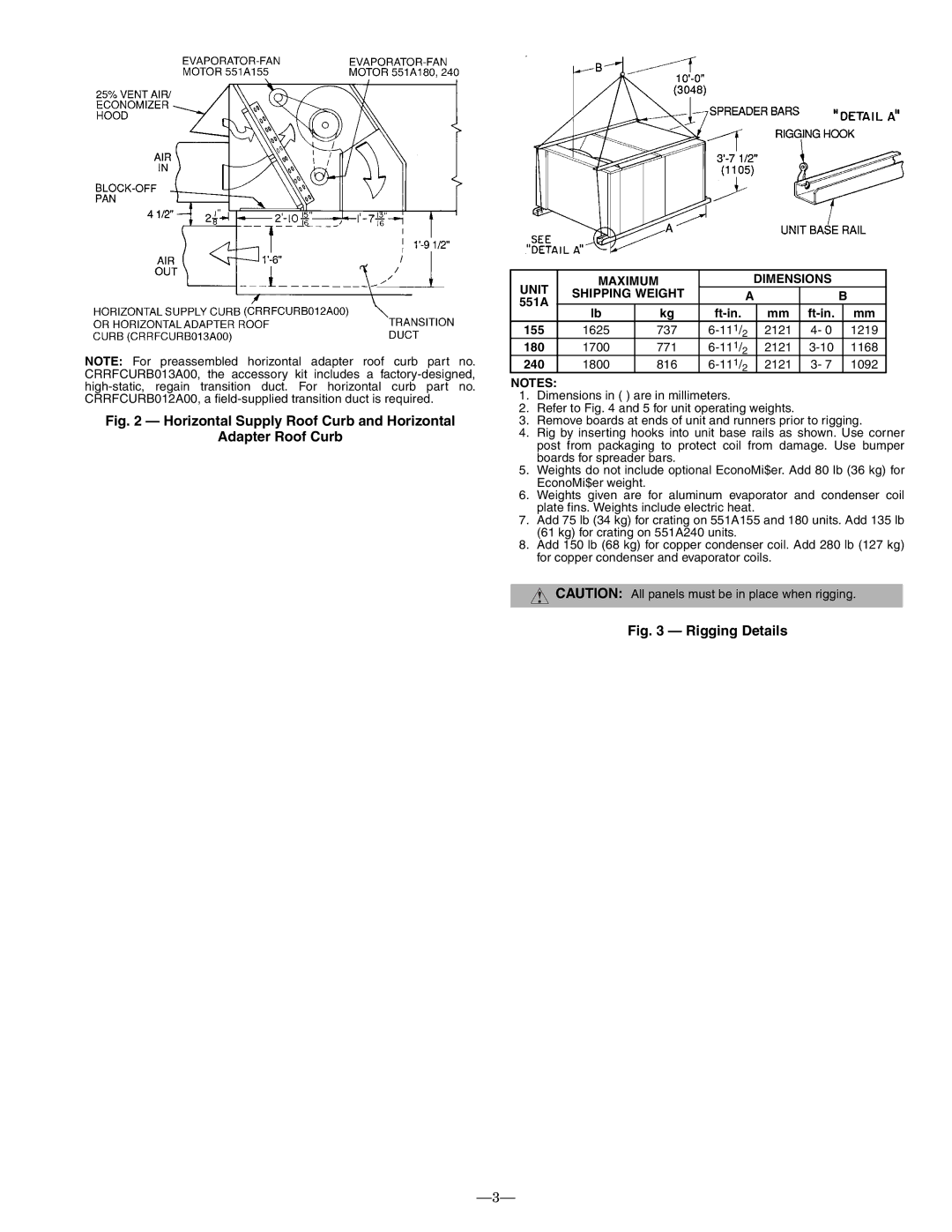

NOTE: For preassembled horizontal adapter roof curb part no. CRRFCURB013A00, the accessory kit includes a

Fig. 2 — Horizontal Supply Roof Curb and Horizontal

Adapter Roof Curb

UNIT | MAXIMUM |

|

| DIMENSIONS |

|

| ||||

SHIPPING WEIGHT |

| A |

| B | ||||||

551A |

|

|

| |||||||

|

| lb | kg |

|

| mm |

|

| mm | |

155 |

| 1625 | 737 | 2 |

| 2121 | 4- 0 |

| 1219 | |

180 |

| 1700 | 771 | 2 |

| 2121 |

| 1168 | ||

240 |

| 1800 | 816 | 2 |

| 2121 | 3- 7 |

| 1092 | |

NOTES:

1.Dimensions in ( ) are in millimeters.

2.Refer to Fig. 4 and 5 for unit operating weights.

3.Remove boards at ends of unit and runners prior to rigging.

4.Rig by inserting hooks into unit base rails as shown. Use corner post from packaging to protect coil from damage. Use bumper boards for spreader bars.

5.Weights do not include optional EconoMi$er. Add 80 lb (36 kg) for EconoMi$er weight.

6.Weights given are for aluminum evaporator and condenser coil plate fins. Weights include electric heat.

7.Add 75 lb (34 kg) for crating on 551A155 and 180 units. Add 135 lb (61 kg) for crating on 551A240 units.

8.Add 150 lb (68 kg) for copper condenser coil. Add 280 lb (127 kg) for copper condenser and evaporator coils.

![]() CAUTION: All panels must be in place when rigging.

CAUTION: All panels must be in place when rigging.