VI. CONDENSER-FAN ADJUSTMENT

A. 551A155 and 180 Units (Fig. 33)

1.Shut off unit power supply.

2.Remove access panel(s) closest to the fan to be adjusted.

3.Loosen fan hub setscrews.

4.Adjust fan height on shaft using a straightedge placed across the fan orifice.

5.Tighten setscrews and replace panel(s).

6.Turn on unit power.

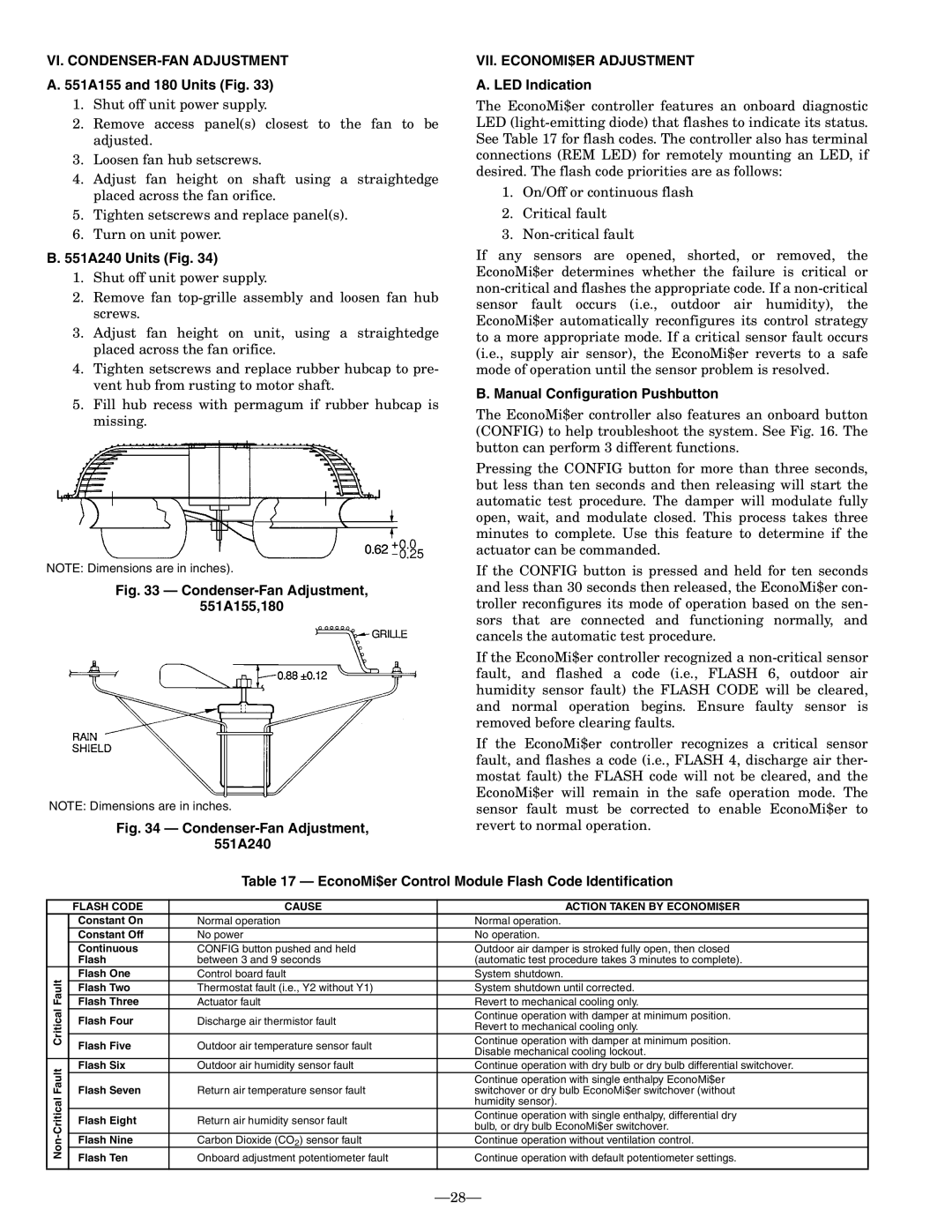

B.551A240 Units (Fig. 34)

1.Shut off unit power supply.

2.Remove fan

3.Adjust fan height on unit, using a straightedge placed across the fan orifice.

4.Tighten setscrews and replace rubber hubcap to pre- vent hub from rusting to motor shaft.

5.Fill hub recess with permagum if rubber hubcap is missing.

NOTE: Dimensions are in inches).

Fig. 33 — Condenser-Fan Adjustment,

551A155,180

NOTE: Dimensions are in inches.

Fig. 34 — Condenser-Fan Adjustment,

551A240

VII. ECONOMI$ER ADJUSTMENT

A. LED Indication

The EconoMi$er controller features an onboard diagnostic LED

1.On/Off or continuous flash

2.Critical fault

3.

If any sensors are opened, shorted, or removed, the EconoMi$er determines whether the failure is critical or

B. Manual Configuration Pushbutton

The EconoMi$er controller also features an onboard button (CONFIG) to help troubleshoot the system. See Fig. 16. The button can perform 3 different functions.

Pressing the CONFIG button for more than three seconds, but less than ten seconds and then releasing will start the automatic test procedure. The damper will modulate fully open, wait, and modulate closed. This process takes three minutes to complete. Use this feature to determine if the actuator can be commanded.

If the CONFIG button is pressed and held for ten seconds and less than 30 seconds then released, the EconoMi$er con- troller reconfigures its mode of operation based on the sen- sors that are connected and functioning normally, and cancels the automatic test procedure.

If the EconoMi$er controller recognized a

If the EconoMi$er controller recognizes a critical sensor fault, and flashes a code (i.e., FLASH 4, discharge air ther- mostat fault) the FLASH code will not be cleared, and the EconoMi$er will remain in the safe operation mode. The sensor fault must be corrected to enable EconoMi$er to revert to normal operation.

Table 17 — EconoMi$er Control Module Flash Code Identification

| FLASH CODE | CAUSE | ACTION TAKEN BY ECONOMI$ER | |

| Constant On | Normal operation | Normal operation. | |

| Constant Off | No power | No operation. | |

| Continuous | CONFIG button pushed and held | Outdoor air damper is stroked fully open, then closed | |

| Flash | between 3 and 9 seconds | (automatic test procedure takes 3 minutes to complete). | |

Fault | Flash One | Control board fault | System shutdown. | |

Flash Two | Thermostat fault (i.e., Y2 without Y1) | System shutdown until corrected. | ||

Flash Three | Actuator fault | Revert to mechanical cooling only. | ||

Critical |

|

| Continue operation with damper at minimum position. | |

| Flash Four | Discharge air thermistor fault | Continue operation with damper at minimum position. | |

| Revert to mechanical cooling only. | |||

|

|

| ||

| Flash Five | Outdoor air temperature sensor fault | Disable mechanical cooling lockout. | |

|

|

| ||

Fault | Flash Six | Outdoor air humidity sensor fault | Continue operation with dry bulb or dry bulb differential switchover. | |

Flash Seven |

| Continue operation with single enthalpy EconoMi$er | ||

Return air temperature sensor fault | switchover or dry bulb EconoMi$er switchover (without | |||

Critical |

|

| humidity sensor). | |

Flash Eight | Return air humidity sensor fault | Continue operation with single enthalpy, differential dry | ||

| bulb, or dry bulb EconoMi$er switchover. | |||

|

|

| ||

Non- | Flash Nine | Carbon Dioxide (CO2) sensor fault | Continue operation without ventilation control. | |

Flash Ten | Onboard adjustment potentiometer fault | Continue operation with default potentiometer settings. | ||

| ||||

|

|

|

|