EASY MAINTENANCE AND INSTALLATION

FEATURES/BENEFITS

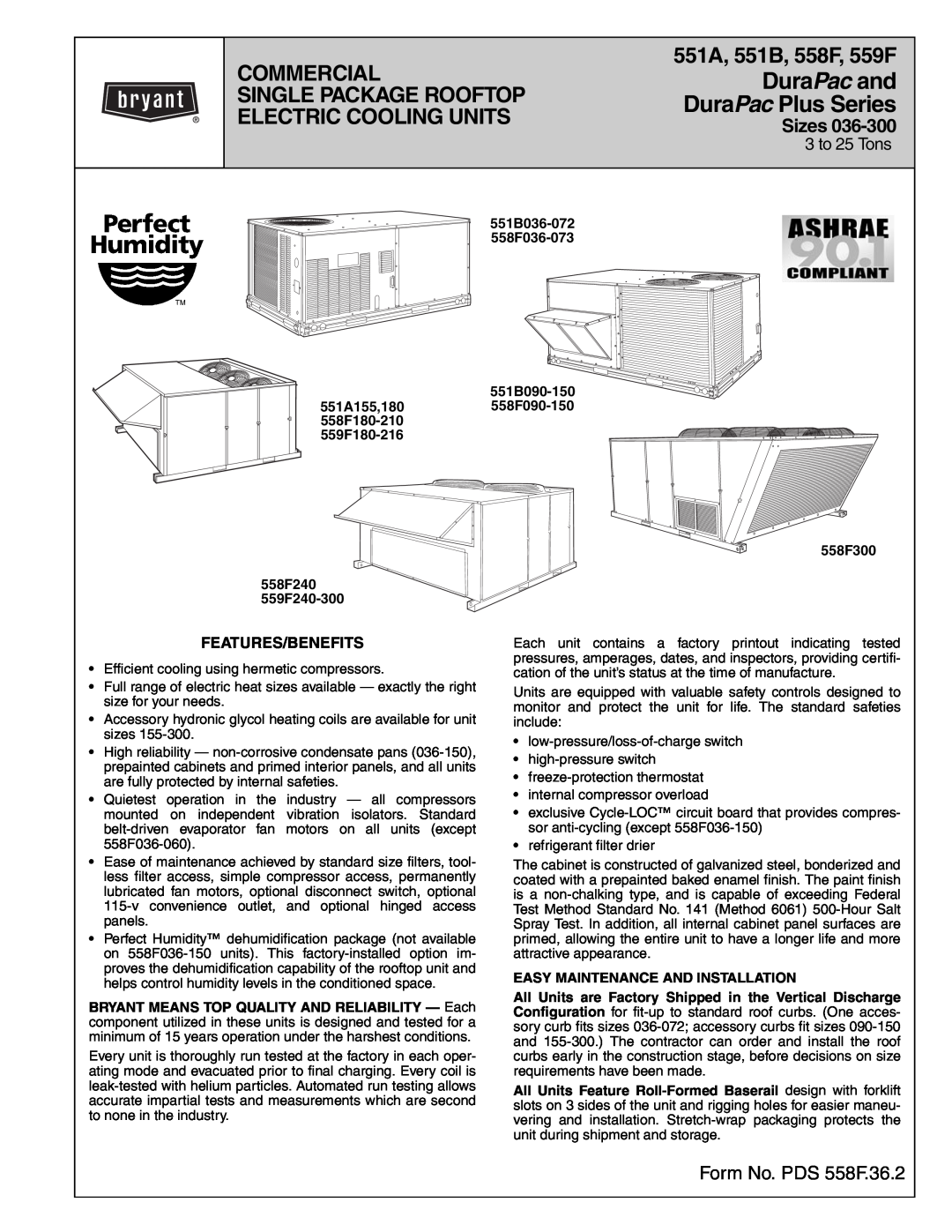

551B036-072 558F036-073 551B090-150 551A155,180558F090-150

558F180-210 559F180-216 558F300 558F240 559F240-300

SERVICEABILITY

Single-Point Electrical Power Connections permit easier

QUIET, EFFICIENT OPERATION AND DEPENDABLE PERFORMANCE

Totally Enclosed Condenser Fan Motors and permanently

Guide Specifications - Sizes

TABLE OF CONTENTS

558F036-150

558F180-300

2. Some options may increase product lead times

OPTIONS AND ACCESSORIES

BAROMETRIC RELIEF/POWER EXHAUST 155-300 Shown

OPTIONS AND ACCESSORIES cont

LOW AMBIENT CONTROLS

CONDENSER COIL PROTECTION APPLICATIONS

DURA-SHIELD CONDENSER COIL OPTIONS

Perfect Humidity DEHUMIDIFICATION PACKAGE

Dura-Shield Option

TIME GUARD CONTROL

LIGHT COMMERCIAL THERMIDISTAT

DURABLADE ECONOMIZER

BRYANT COMMERCIAL THERMOSTAT

CONVENIENCE OUTLET

UNIT-MOUNTED DISCONNECT Sizes

Factory-installed, internally-mounted, NEC National Electri- cal Code and UL Underwriters’ Laboratories approved non-fused switch provides unit power shutoff with disconnect lockout protection capability. The switch is accessible from outside the unit

COIL GUARD GRILLE 036-150 Only

HAIL GUARD

CONTROL BOX HINGED PANEL OPTION 581B036-072 UNITS

COMPRESSOR HINGED PANEL OPTION 581B090-150 UNITS SHOWN

FILTER HINGED PANEL OPTION

EVAPORATOR-FAN HINGED PANEL OPTION

LP CONVERSION KIT

581B036-072

OPERATING SEQUENCE - SIZE 036-073 UNITS

CONTROLS

OPERATING SEQUENCE - SIZE 090-150 UNITS

SEQUENCE OF OPERATION SIZES

CONTROLS cont

Perfect Humidity Dehumidification Option

TYPICAL WIRING SCHEMATIC Single Fan Units, Sizes

EconoMi$er

TYPICAL WIRING SCHEMATIC Two-Fan Units, Size

ACTUATOR

TYPICAL WIRING SCHEMATIC Sizes

3. Jumpers are omitted when unit is equipped with EconoMi$er

EconoMi$er Wiring

TYPICAL WIRING SCHEMATIC cont

Non-Fused Disconnect Optional

Vertical Discharge Ducting

TYPICAL PIPING AND WIRING - SIZES

Horizontal Discharge Ducting

2. Installation must comply with all applicable codes

10. MAXIMUM OPERATING OUTDOOR-AIR TEMPERATURE

APPLICATION DATA

12. PERFECT HUMIDITY DEHUMIDIFICATION PACKAGE

Concentric Duct Distribution Unit Sizes

Applications

APPLICATION DATA cont

c. MUSEUMS AND LIBRARIES - Humidity can damage books and artwork

15. PERFECT HUMIDITY DEHUMIDIFICATION PACKAGE FEATURES AND BENEFITS

Pressure Enthalpy Curve

Without Subcooler

Psychrometric Chart 551B072 Shown

Point 3 - Leaving Air F 63.0 db/56.8 wb With Subcooler

db - Dry Bulb wb - Wet Bulb

558F036

MODEL NUMBER NOMENCLATURE - 558F

ARI* CAPACITY RATINGS

558F E X 090 000 KB

558F036

PHYSICAL DATA - 558F036-073

558F036

PHYSICAL DATA - 558F090-150

558F036-150

BASE UNIT DIMENSIONS - 558F036-072

BASE UNIT DIMENSIONS - 558F073

558F036-150

BASE UNIT DIMENSIONS - 558F090,102,120,150

BASE UNIT DIMENSIONS - 558F091,121

ACCESSORY DIMENSIONS

ACCESSORY DIMENSIONS cont

I DETERMINE COOLING AND HEATING REQUIRE- MENTS AT DESIGN CONDITIONS

SELECTION PROCEDURE with 558F048 example

II SELECT UNIT BASED ON REQUIRED COOLING CAPACITY

III SELECT ELECTRIC HEAT

COOLING CAPACITIES

PERFORMANCE DATA

over

COOLING CAPACITIES cont

PERFORMANCE DATA cont

PERFORMANCE DATA cont

558F036-150

COOLING CAPACITIES cont

558F036-150

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

558F036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

558F036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

558F036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

558F036-150

4. Interpolation is permissible. Do not extrapolate

GENERAL FAN PERFORMANCE NOTES

ACCESSORY/FIOP STATIC PRESSURE* in. wg - 558F090-150

ACCESSORY/FIOP STATIC PRESSURE in. wg - 558F036-073

FAN RPM AT MOTOR PULLEY SETTINGS

EconoMi$er Power Exhaust Performance 558F090-150

EconoMi$er Power Exhaust Performance 558F036-073

OUTDOOR SOUND DATA Total Unit

EVAPORATOR-FAN MOTOR EFFICIENCY

CONTINUOUS BHP

EVAPORATOR-FAN MOTOR PERFORMANCE

MULTIPLICATION FACTORS

ELECTRIC HEATING CAPACITIES

ELECTRICAL DATA - 558F036-073

ELECTRICAL DATA - 558F036-073 cont

ELECTRICAL DATA - 558F036-073 cont

ELECTRICAL DATA - 558F090-150

ELECTRICAL DATA - 558F090-150 cont

2. Unbalanced 3-Phase Supply Voltage

LEGEND AND NOTES FOR ELECTRICAL DATA TABLES PAGES

551B036-150

MODEL NUMBER NOMENCLATURE - 551B

551B E X 090 000 DA

PHYSICAL DATA - 551B036-072

High Efficiency Enhanced Copper Tubes, Aluminum Double-Wavy Fins

PHYSICAL DATA - 551B090-150

Acutrol Metering Device

BASE UNIT DIMENSIONS - 551B036-072

551B036

551B036-150

BASE UNIT DIMENSIONS - 551B090-150

ACCESSORY DIMENSIONS - 551B036-072

ACCESSORY DIMENSIONS - 551B090-150

IV DETERMINE FAN SPEED AND POWER REQUIRE- MENTS AT DESIGN CONDITIONS

SELECTION PROCEDURE With 551B048 Example

V DETERMINE NET CAPACITIES

tldb = tedb

COOLING CAPACITIES, STANDARD UNITS

hlwb = hewb

551B036

COOLING CAPACITIES, STANDARD UNITS cont

551B036

COOLING CAPACITIES, UNITS WITH PERFECT HUMIDITY OPTION

551B036

COOLING CAPACITIES, UNITS WITH PERFECT HUMIDITY OPTION cont

PERFORMANCE DATA CONT

551B036

551B036

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

FAN PERFORMANCE - VERTICAL DISCHARGE UNITS cont

PERFORMANCE DATA cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS

PERFORMANCE DATA cont

PERFORMANCE DATA cont

551B036-150

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

551B036-150

PERFORMANCE DATA cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

FAN PERFORMANCE - HORIZONTAL DISCHARGE UNITS cont

FAN RPM AT MOTOR PULLEY SETTING* HIGH-STATIC MOTOR/DRIVE

FAN RPM AT MOTOR PULLEY SETTING* STANDARD MOTOR/DRIVE

EVAPORATOR-FAN MOTOR PERFORMANCE - STANDARD MOTOR

EVAPORATOR-FAN MOTOR PERFORMANCE - HIGH-STATIC MOTORS

ACCESSORY/FIOP ECONOMIZERS AND

ELECTRIC HEATERS STATIC PRESSURE DROP in. wg 551B036-072

ELECTRIC HEATERS STATIC PRESSURE DROP in. wg 551B090-150

Horizontal EconoMi$er Barometric Relief Damper Characteristics

Vertical EconoMi$er Barometric Relief Damper Characteristics

EconoMi$er Power Exhaust Performance

EconoMi$er Power Exhaust Performance 551B036-072

Vertical EconoMi$er Outdoor-Air Leakage

OUTDOOR SOUND POWER TOTAL UNIT

Vertical EconoMi$er Return-Air Pressure Drop

Horizontal EconoMi$er Return-Air Pressure Drop

LEGEND AND NOTES FOR ELECTRICAL DATA TABLES

STANDARD MOTOR UNITS WITHOUT ELECTRICAL CONVENIENCE OUTLET

ELECTRICAL DATA

STANDARD MOTOR UNITS WITHOUT ELECTRICAL CONVENIENCE OUTLET cont

ELECTRICAL DATA cont

STANDARD MOTOR UNITS WITH ELECTRICAL CONVENIENCE OUTLET

STANDARD MOTOR UNITS WITH ELECTRICAL CONVENIENCE OUTLET cont

HIGH-STATIC MOTOR UNITS WITHOUT ELECTRICAL CONVENIENCE OUTLET

551B090††

HIGH-STATIC MOTOR UNITS WITHOUT ELECTRICAL CONVENIENCE OUTLET cont

551B102††

551B120††

HIGH-STATIC MOTOR UNITS WITH ELECTRICAL CONVENIENCE OUTLET

HIGH-STATIC MOTOR UNITS WITH ELECTRICAL CONVENIENCE OUTLET cont

558F/551B036-150

GUIDE SPECIFICATIONS - SIZES

PART 1 - GENERAL

PART 2 - PRODUCTS

GUIDE SPECIFICATIONS - SIZES 036-150 cont

13. High-Static Motor and Drive 036-120 3-phase units only

5 5 9 F E X 1 8 0 0 0 0 A H C B

MODEL NUMBER NOMENCLATURE - 559F

AIR QUANTITY LIMITS

LOW OUTDOOR TEMPERATURE OPERATING LIMITS F

ARI* CAPACITY RATINGS cont

559F180-300

ELECTRIC RESISTANCE HEATER DATA - 559F180-300

Aluminum Pre-Coated, or Copper Plate Fins

PHYSICAL DATA - 559F180-300

Copper Plate Fins, Face Split

OPTIONS AND ACCESSORIES Weight Adders

OPERATING AND RIGGING WEIGHTS

PHYSICAL DATA - 559F180-300 cont

300-559F180

BASE UNIT DIMENSIONS - 559F180-216

BASE UNIT DIMENSIONS - 559F240-300

DIMENSIONS degrees and inches

Horizontal and Vertical Roof Curbs and Horizontal Adapter Curb

Barometric Relief/Power Exhaust

Horizontal Supply/Return Adapter Installation

Factory-Installed Non-Fused Disconnect

Factory-Installed Convenience Outlet

K.O. - Knockout

III DETERMINE FAN SPEED AND POWER REQUIRE- MENTS AT DESIGN CONDITIONS

SELECTION PROCEDURE with 559F180 example

I DETERMINE COOLING REQUIREMENTS AT DESIGN CONDITIONS

IV DETERMINE NET COOLING CAPACITY

over

559F180-300

Above 80 F edb, add corr factor x cfm to SHC

tldb

559F180

tlwb =

hlwb =

FAN PERFORMANCE - 559F180-300 UNITS

GLYCOL HEATING PERFORMANCE

FAN PERFORMANCE - 559F180-300 UNITS cont

559F180

ACCESSORY/FIOP STATIC PRESSURE in. wg* - 559F180

OUTDOOR SOUND POWER

ACCESSORY/FIOP STATIC PRESSURE in. wg* - 559F216-300

Horizontal Supply/Return Fan Performance with CRRFCURB013A00

Fan Performance Using Accessory Power Exhaust 559F180-300

High Static Regain Adapter

20 Tons

3 Ph, 60 Hz

559F180-300

558F180-300

MODEL NUMBER NOMENCLATURE - 558F180-300

5 5 8 F E X 2 1 0 0 0 0 A A A A

3750

ELECTRIC RESISTANCE HEATER DATA - 558F180-300

558F180

PHYSICAL DATA - 558F180-300

PHYSICAL DATA - 558F180-300 cont

BASE UNIT DIMENSIONS - 558F180

558F180

BASE UNIT DIMENSIONS - 558F240

BASE UNIT DIMENSIONS - 558F300

Standard curb for

Standard curb

units requiring

Side supply and

2 ′-0 ″

PACKAGE NO

Pre-Assembled, High Static

Horizontal Adapter

Factory-Installed Convenience Outlet

SELECTION PROCEDURE with 558F240 Example

558F180

COOLING CAPACITIES LEGEND AND NOTES

This accessory glycol coil is intended for use with a MINIMUM of 25% glycol

558F180

FAN PERFORMANCE - 558F180-300 UNITS

FAN PERFORMANCE - 558F180-300 UNITS cont

ACCESSORY/FIOP STATIC PRESSURE in. wg* - 558F180-300

Fan Performance Using Accessory Power Exhaust 558F180-300

ELECTRICAL DATA - 558F180-300

ELECTRICAL DATA - 558F180-300 cont

551A155-180

MODEL NUMBER NOMENCLATURE - 551A

551A E X 155 000 AJ C B

COOLING OPERATION AIR QUANTITY LIMITS

INDOOR SOUND DATA TOTAL UNIT

ELECTRIC RESISTANCE HEATER DATA

Face Split

PHYSICAL DATA - 551A155,180

PHYSICAL DATA cont

OPTIONS AND ACCESSORIES

Weight Adders

BASE UNIT DIMENSIONS - 551A155,180

551A155-180

ACCESSORY DIMENSIONS

Horizontal Supply/Return Adapter Installation

ACCESSORY DIMENSIONS cont

Barometric Relief/Power Exhaust

551A155-180

Factory-Installed Convenience Outlet

VI SELECT THE UNIT THAT CORRESPONDS TO POWER SOURCE AVAILABLE

SELECTION PROCEDURE

V DETERMINE NET COOLING CAPACITIES

ENTERING AIR DRY-BULB TEMP F

BYPASS

FACTOR

551A155

ENTERING AIR DRY-BULB TEMP F

under

FACTOR

551A155

FAN PERFORMANCE - 551A155,180 UNITS

FAN PERFORMANCE - 551A155,180 UNITS cont

ACCESSORY/FIOP STATIC PRESSURE in. wg - 551A155,180 UNITS

ACCESSORY/FIOP STATIC PRESSURE in. wg* - 551A155,180

EVAPORATOR FAN MOTOR PERFORMANCE

Fan Performance Using Accessory Power Exhaust 551A155,180

551A155

ELECTRICAL DATA - 551A155,180

551A/558F/559F155-300

1. Unit shall be capable of starting and running at 125 F

GUIDE SPECIFICTIONS - SIZES 155-300 cont

ambient outdoor temperature per maximum load cri

gas passing through motor windings and shall have

GUIDE SPECIFICATIONS - SIZES 155-300 cont

551A/558F/559F155-300

21-25

INDEX

89-92

50-60

UNIT MUST BE INSTALLED IN ACCORDANCE WITH INSTALLATION INSTRUCTIONS

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Copyright 2002 Bryant Heating & Cooling Systems

Printed in U.S.A