Fig. 10 — Condensate Drain Piping Details

VI. STEP 6 — MAKE ELECTRICAL CONNECTIONS A. Field Power Supply

Unit is factory wired for voltage shown on nameplate.

When installing units, provide a disconnect, per NEC (National Electrical Code) requirements, of adequate size (Table 2). Electrical heater data is shown in Table 3.

All field wiring must comply with NEC and local require- ments.

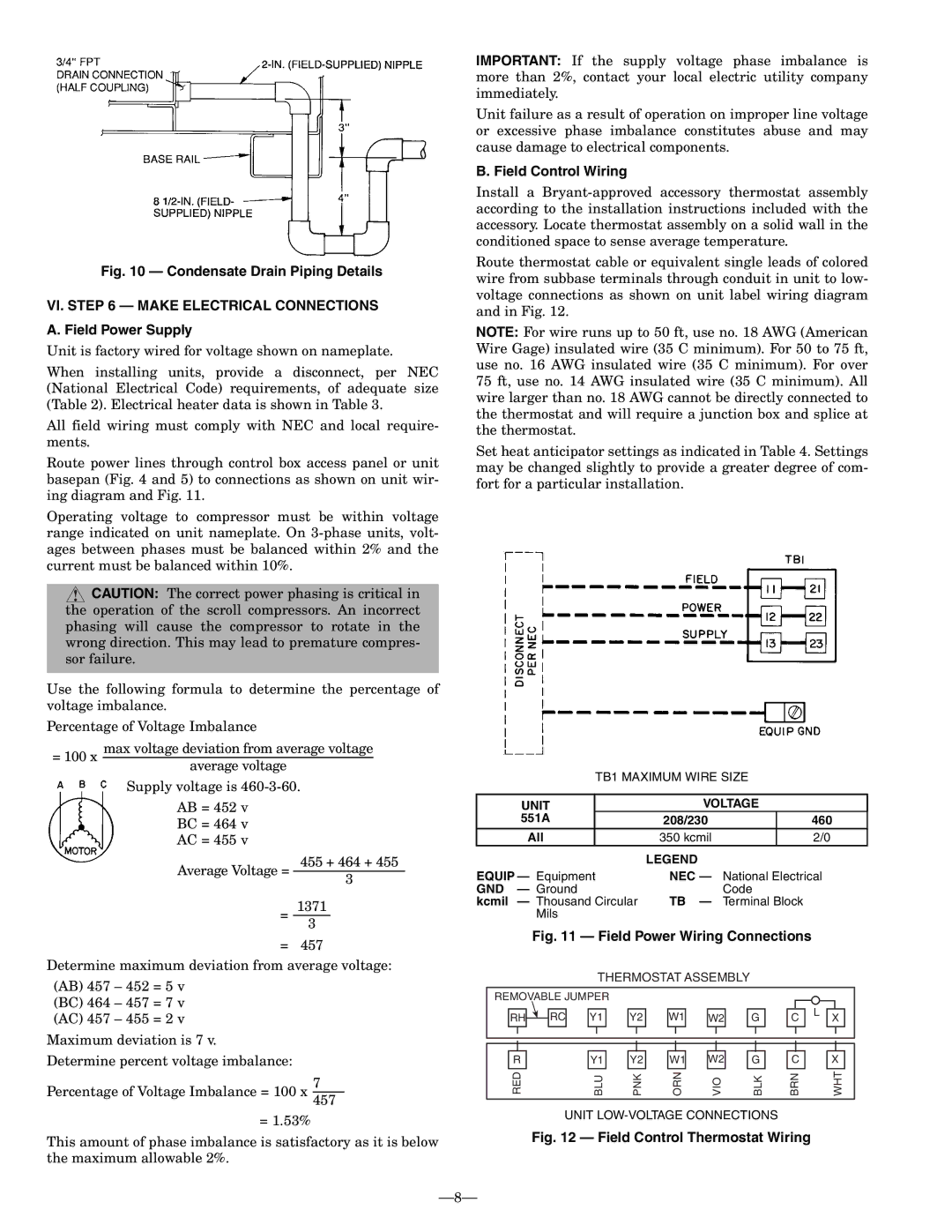

Route power lines through control box access panel or unit basepan (Fig. 4 and 5) to connections as shown on unit wir- ing diagram and Fig. 11.

Operating voltage to compressor must be within voltage range indicated on unit nameplate. On

![]() CAUTION: The correct power phasing is critical in the operation of the scroll compressors. An incorrect phasing will cause the compressor to rotate in the wrong direction. This may lead to premature compres- sor failure.

CAUTION: The correct power phasing is critical in the operation of the scroll compressors. An incorrect phasing will cause the compressor to rotate in the wrong direction. This may lead to premature compres- sor failure.

Use the following formula to determine the percentage of voltage imbalance.

Percentage of Voltage Imbalance

=100 x max voltage deviation from average voltage average voltage

EXAMPLE: Supply voltage is

AB = 452 v

BC = 464 v

AC = 455 v

455 + 464 + 455

Average Voltage =

3

= 1371 3

= 457

Determine maximum deviation from average voltage:

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance:

Percentage of Voltage Imbalance = 100 x 7457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately.

Unit failure as a result of operation on improper line voltage or excessive phase imbalance constitutes abuse and may cause damage to electrical components.

B. Field Control Wiring

Install a

Route thermostat cable or equivalent single leads of colored wire from subbase terminals through conduit in unit to low- voltage connections as shown on unit label wiring diagram and in Fig. 12.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft, use no. 16 AWG insulated wire (35 C minimum). For over 75 ft, use no. 14 AWG insulated wire (35 C minimum). All wire larger than no. 18 AWG cannot be directly connected to the thermostat and will require a junction box and splice at the thermostat.

Set heat anticipator settings as indicated in Table 4. Settings may be changed slightly to provide a greater degree of com- fort for a particular installation.

TB1 MAXIMUM WIRE SIZE

| UNIT |

|

|

|

| VOLTAGE |

|

|

|

| ||

| 551A |

|

|

| 208/230 |

|

|

| 460 |

| ||

| All |

|

|

| 350 kcmil |

|

|

| 2/0 |

|

| |

|

|

|

|

| LEGEND |

|

|

|

|

|

|

|

EQUIP — Equipment |

| NEC — | National Electrical |

|

| |||||||

GND — Ground |

|

|

|

|

| Code |

|

|

|

| ||

kcmil — Thousand Circular | TB | — | Terminal Block |

|

|

| ||||||

| Mils |

|

|

|

|

|

|

|

|

|

|

|

| Fig. 11 — Field Power Wiring Connections |

|

|

| ||||||||

|

|

| THERMOSTAT ASSEMBLY |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |

| REMOVABLE JUMPER |

|

|

|

|

|

|

|

|

| ||

| RH RC | Y1 | Y2 | W1 | W2 | G | C | L | X |

| ||

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

| R | Y1 | Y2 | W1 | W2 | G | C |

| X |

| ||

| RED |

| BLU | PNK | ORN |

| VIO | BLK | BRN |

| WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNIT